Plant Optimization Methodology for Battery Manufacturers

Delivering optimized design, project execution excellence, and efficient ongoing operations

The global Lithium-ion battery manufacturing industry is expanding rapidly in response to burgeoning energy requirements. Along with demand, challenges are also growing.

In battery production, these five challenges are the most widely reported—with production efficiency leading the list.

- Improving quality while reducing off-spec material

- Enhancing throughput and maximizing OEE

- Managing cost pressures with decreasing battery prices

- Moving from start-up through scale up

- Ensuring safety and environmental responsibility

Forward-thinking battery manufacturers work to overcome these challenges before the plant is even built. ABB helps design, equip, and operationalize plants, helping improve project execution while also ensuring safety, efficiency, and flexibility at every stage of the lifecycle.

Partner with ABB from the project beginning for the fastest time to market

ABB Plant Optimization Methodology delivers optimized design, project execution excellence, and efficient and integrated operations for battery manufacturers. What does that mean to you?

Capex savings of

15-40%

Start-up hours reduction of

~40%

Schedule compression of

10-30%

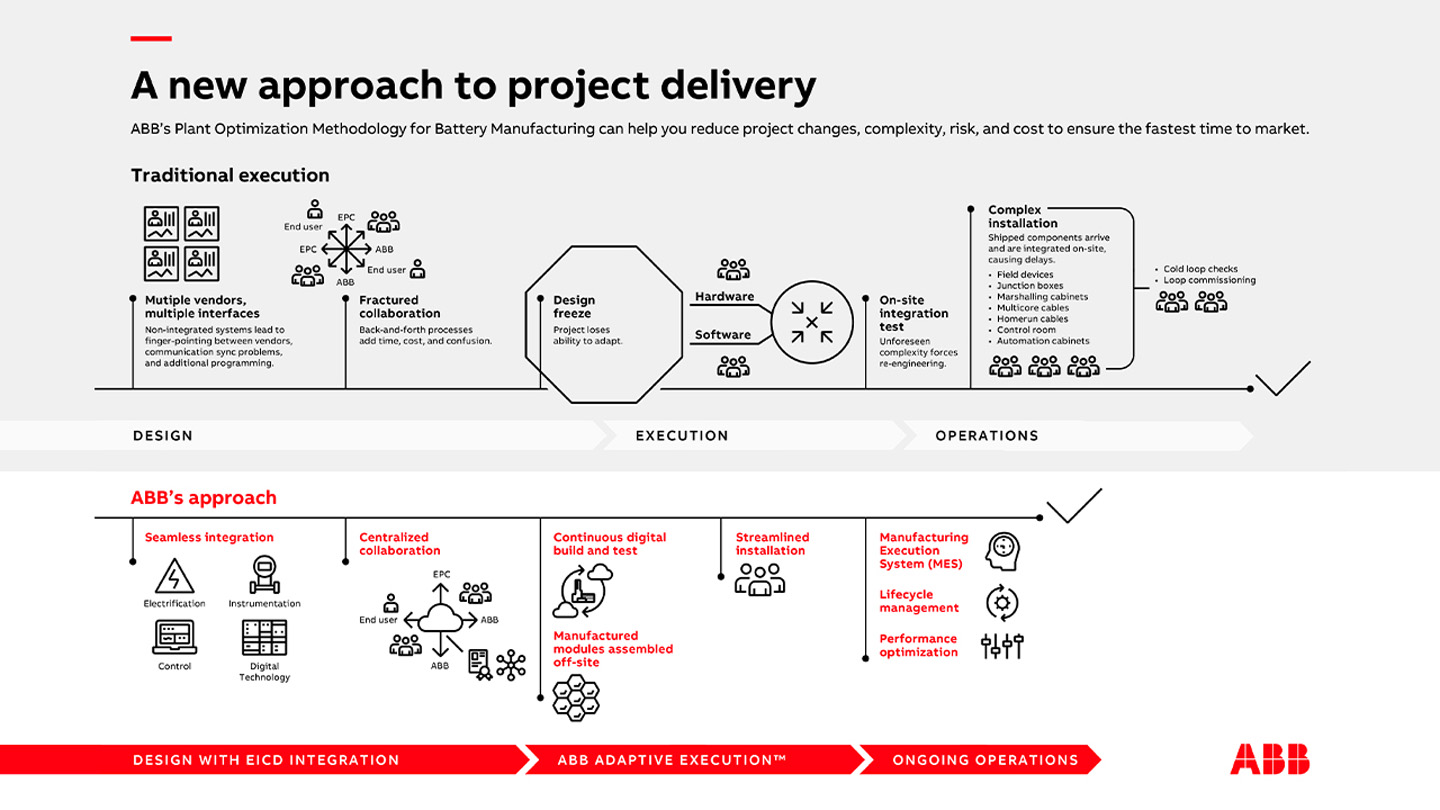

This integrated offering is built upon a solid foundation comprising EICD integration, ABB Adaptive Execution™, and Ongoing operations. By helping you preserve schedules and reduce project changes, ABB helps you achieve the fastest time to market while reducing complexity, risk, and cost.

Learn more about the three pillars of Plant Optimization Methodology

Proven approach for greenfield sites

Plant Optimization Methodology brings together the best people, processes, and infrastructure, as well as the industry-leading technologies to help our customers achieve their goals. See how we supported Tier One* battery supplier Northvolt in saving time and money as they sought to build their first Gigafactory in Skellftea, Sweden:

Learn more

-

Contact us Submit your inquiry and we will contact you

Contact us -

Find a channel partner Quickly find an ABB channel partner

Find a channel partner