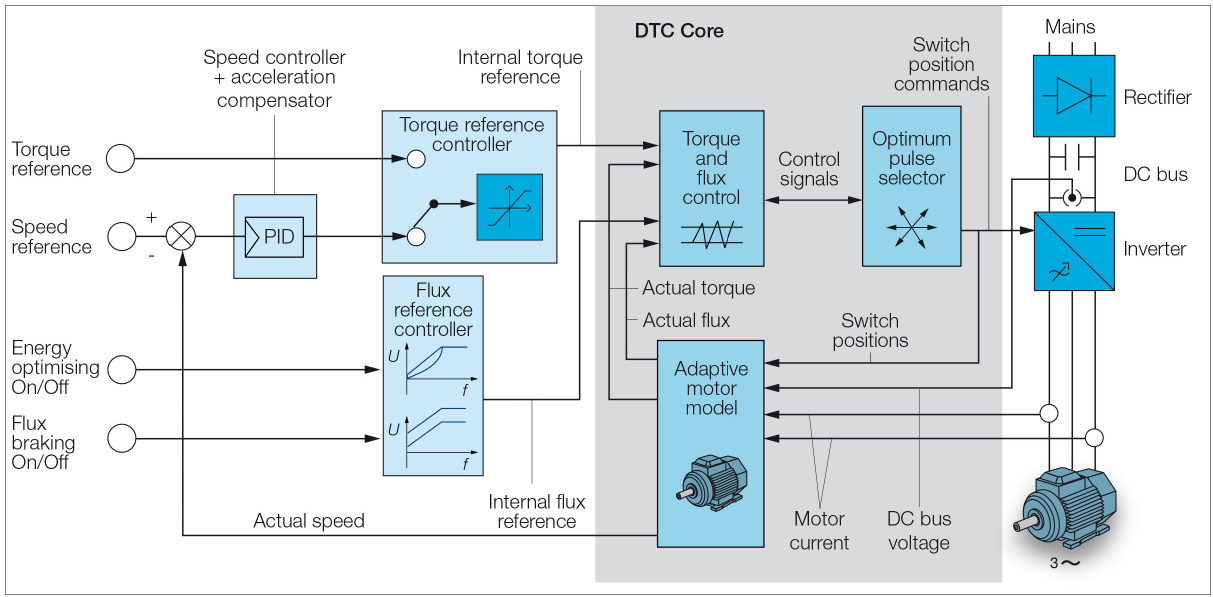

Variable-speed drives (VSDs) have enabled unprecedented performance in electric motors and delivered dramatic energy savings by matching motor speed and torque to the driven load requirements. Most VSDs in the market rely on a modulator stage that conditions voltage and frequency inputs to the motor, but causes inherent time delay in processing control signals. In contrast, premium ABB drives employ innovative direct torque control (DTC)—greatly increasing motor torque response. DTC technology also provides other benefits ranging up to system-level features.

High-performance AC drives from ABB offer an innovative technology called direct torque control (DTC). As the name suggests, the method controls motor flux and torque directly, instead of trying to control motor currents indirectly like AC vector drives and DC drives. This means better accuracy in matching the driven system’s load requirements. Originated by one of the founding companies of ABB and patented in the mid-1980s, DTC eliminates the need for an extra modulator stage thus achieving control dynamics close to the theoretical maximum.

When ABB introduced its first direct torque control AC drive to the market in 1995, DTC was already a leading technology. Subsequent improvements in processor computational power, application programming, and communication interfaces have continually enabled higher DTC performance, providing premium motor control for a broad range of applications.