Ben Goossens ABB Continuous Gas Analyzers, Frankfurt am Main, Germany, ben.goossens@be.abb.com; Karsten Brink Floor Managing Director, FLO2R, Hadsund, Denmark

With over 30 years of experience and more than 600 kiln systems supplied worldwide, ABB is the market leader in providing gas analyzers for cement plants. These analyzers are indispensable for this application as they play a crucial role in ensuring optimal operational efficiency, compliance with environmental regulations and the effective utilization of fuels and raw materials.

Analysis systems are installed at the inlet of the cement kiln to monitor and analyze the composition of gases entering the cement-making process, offering operators valuable information on combustion efficiency and emission levels. Gases monitored include oxygen (O₂), carbon dioxide (CO₂), nitrogen oxides (NOx) sulfur dioxide (SO₂) and carbon monoxide (CO). O₂ exit concentrations, for example, are used as a kind of lambda sensor to help set kiln operating parameters. CO measurements, as another example, indicate process O₂ deficiency or surplus and give early warning of potentially explosive conditions developing, especially at start-up or shut-down or under process imbalance conditions.

The harsh environment found at the kiln inlet precludes the use of in-situ equipment, so the dominant commercially available devices rely on sample-extraction designs. However, the introduction of new processes and additives and, increasingly, alternative fuels and raw material (AFR), is testing sample extraction probes to the limits. The most serious detrimental effect seen is scaling on the probe surface and sample intake area. Material fall-through in the kiln riser duct has also become more frequent, increasing the risk of probe damage.

With the increased use of AFR (some plants may use up to 95 percent AFR), complete combustion can be more difficult to achieve than with conventional fuels. Further, due to the greater weight and more complex composition of AFR, it is more liable to fall and burn in direct contact with the bed material of the kiln, causing localized unfavorable conditions or damage. AFR can also increase the quantity of vaporized volatile components in the kiln. These factors make reliable gas sampling all the more necessary.

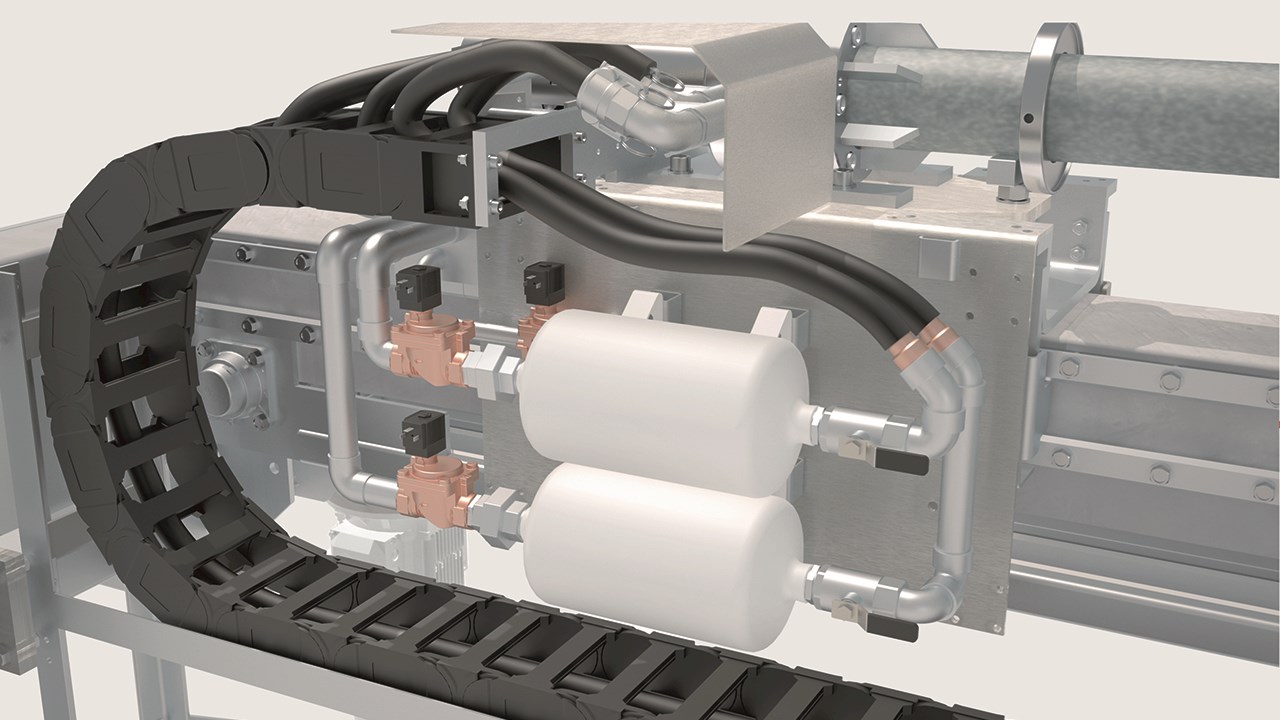

02a “X-ray” view.

02b Schematic.

02 ABB’s patented ProKiln probe.

ABB’s patented ProKiln probe is a response to the challenges created by these new process conditions. The probe – developed in collaboration with FLO2R, a Danish company with long-established and deep knowledge of kiln inlet measurement – focuses on a more powerful probe cleaning regime and increased mechanical strength →01-02.

Clean and robust sampling

ABB’s ProKiln’s main component is a 3 m-long, water-cooled probe with an extractive filter at the sampling end →02. Two powerful air blasters that blow through up to six internal pipes (to reduce pressure drop – a key design requirement) provide sample flow and cleaning. The probe is installed on a buggy running on a retraction device →03. A failsafe is provided to extract the probe in the event of a power failure (for installations without an uninterruptible power supply, an additional pneumatic motor is included). The buggy retractor runs on debris-resistant tracks that prevent obstruction by foreign material.

A control cabinet with a human-machine interface (HMI) operates and powers the system and connects it to any gas analysis system – of either hot/wet or cold/dry types. The cabinet features common serial interfaces for easy connection to the plant control room. A second unit external to the probe contains the recirculating, non-pressurized cooling system.

Extractive filter in the probe tip

The device’s most critical interface is the filter through which sample gas is separated from the process dust. This filter is located inside the probe cooling jacket, which protects it from direct impacts and eliminates the long sampling pipe in incumbent devices in which dust and sample can combine to form a sticky, pipe-blocking residue. The filtered sample gas is transported away via a constant-temperature (180 °C) heated tube.

Double air blaster cleaning of the probe tip

To avoid complications inside a probe exposed to a 1,200 °C process, the two sample-taking air blasters are also employed to clean the probe tip and filter periphery →04. This is accomplished by a novel 3-D-printed stainless steel nozzle arrangement that allows one blaster to direct air through the center of the probe and filter while the other delivers air to the base of the filter, which cleans the periphery and surface of the filter, blowing any dust back into the process.

Strong mechanical design is needed

The probe design is based on a 4-inch high-temperature austenitic stainless steel pipe. The heavy probe construction is reinforced at the base, much like a kiln burner. The heavy-duty design allows the probe to survive material fall-through from the riser duct. A heat monitoring system continuously evaluates the process conditions and material build-up on and around the probe, triggering the kiln’s standard air blasters in the inlet area when needed.

Simple layout and standard materials

All probe assemblies are based on standard flanges, O-rings, cutting rings, unions and other standard elements. The center pipe that connects one air blaster to the front cleaning nozzle also provides full and easy access for inspection of the entire probe length without using any tools. This examination is possible even when the probe is fully inserted into the process.

The two air blasters are located on the side of the buggy behind a detachable panel →03. The probe package has clean lines and a sturdy layout with only those parts needed for probe operation exposed.

Probing probe performance – field tes

As a part of the product development, tests were conducted at a Holcim plant in Lägerdorf, Germany. The objectives of the trial were to validate:

• System safety

• Maintenance performance – for at least six months of operation

• Probe strength

• Material choices for process and sample parts

• Probe and retractor ability to remove scaling

• Efficiency of air blaster cleaning in a process using AFR with high concentrations of volatiles

• Gas analysis results from the new probe

A test probe was installed in mid-2021. The test installation was equipped with an automated flange to protect personnel and equipment in the event of an overpressure event. The probe was safety cleared for automatic operation and testing continued for over 10 months.

Two modifications were made during the test: the automated flange was strengthened and the probe tip inlet design was changed to provide a more stable flow under conditions of heavy scaling at the inlet.

The use of standard maintenance procedures and materials was very successful and easy to grasp for maintenance personnel (no special training is needed). Typical preventive maintenance and inspection required less than 15 minutes each week.

During the test period, material falling from the riser duct struck the probe several times, with no consequent probe harm. A complete inspection of all internal and external parts after seven and 10 months of operation revealed no corrosion or damage. Indeed, a hard oxidized layer had formed on the surface of the probe that provided additional protection.

The plant used fuels originating from 17 different AFRs during the trial period, resulting in significant fluctuations of the O₂ and CO process values and giving very light to very heavy scaling. Despite these conditions, the probe functioned reliably in automatic operation and no manual cleaning was required – regular cleaning cycles were adequate and during times of heavy scaling, a sample vacuum sensor would initiate additional automatic cleaning. A run factor of over 95 percent was achieved, proving the design and confirming that a double-probe implementation (which is available) will provide a 100 percent run factor →05.

The test kiln had an existing extractive gas analysis system installed in the kiln inlet, which allowed a comparison of results. Even though the analyzers were not supplied with sample gases obtained at the same time and the existing system had a considerably longer sample time, a comparison test showed agreement to within 10 percent.

Cementing the future

The use of AFR in the cement industry has created a more challenging environment for gas analysis equipment due to higher concentrations of volatiles. At the same time, the increased complexities of the process make accurate gas analysis more critical if operations are to achieve efficient combustion, improve quality, reduce emissions and environmental footprint, comply with environmental regulations and effectively incorporate AFR. The ProKiln probe has shown itself capable of facilitating efficacious kiln inlet gas analysis under even the harshest conditions. The return on the investment involved in installing this simple and strong probe can easily be justified by preventing kiln stops alone.

As the industry evolves, gas analysis technology such as ProKiln will remain critical in driving the cement sector toward a greener and more efficient future.

Photo fig. 01: © Drpixel/stock.adobe.com