Until now, the programming of robot motion has been a cumbersome manual task requiring advanced skills. ABB’s new RobotStudio® Automatic Path Planning is radically changing this paradigm. The tool reduces offline robot motion programming to a few clicks and produces motions that outperform those developed by robotics experts in several areas. In short, robots can now be told what to do but are free to translate such orders into the motions that best meet their capabilities and the requirements of their environment.

Nima Enayati, Arne Wahrburg ABB Corporate Research, Ladenburg, Germany, nima.enayati@de.abb.com, arne.wahrburg@de.abb.com; Mikael Norrlof, Mattias Björkman, Morten Akerblad ABB Robotics & Discrete Automation, Västerås, Sweden, mikael.norrlof@se.abb.com, mattias.bjorkman@se.abb.com, morten.akerblad@se.abb.com; Magnus Seger ABB Robotics & Discrete Automation, Gothenburg, Sweden, magnus.seger@se.abb.com

Many decades ago, when people started mimicking robot movements in dances, their jerky and sudden movements were meant as a caricature of the state of the art in robotic motion planning. Today, however, such motions are miles away from being an accurate representation of the state of the art. Nevertheless, since robot programming is difficult and time consuming, inefficient robot programs are still ubiquitous. Even expert robot programmers may produce programs that are not optimal. The reason for this is that articulated robots live in a different mathematical space (a so-called joint space governed by six dimensions) rather than our 3D world.

In practical terms, this means that what humans consider to be the shortest path between two points is very different when translated into the equivalent path for a robot’s joint actuators. Furthermore, the idea of manually optimizing a robot’s every move may not be the best use of resources in a business – a factor that is particularly salient for smaller companies that may lack advanced robotics knowledge. In view of these trends, it is time to start moving toward a world in which robot programming is left to the robots themselves. In short, a user should just tell a robot what needs to be done, and not have to bother with how the robot translates such input into specific individual movements.

Task and transfer motions

A typical industrial robot program can be divided into task-related and transfer motions. The former includes tasks such as welding, gluing, sanding, and tightening screws, where the robot path is for the most part dictated by the task. In most transfer motions and some task-related motions (eg, material handling), the robot path is typically not required to follow a pre-defined geometry, and the user is only interested in the robot traveling from one part of a cell to another in a time-efficient manner. To program such a transfer motion between a start and a goal, a robot programmer iteratively adds via points and checks whether the robot and its attachments remain free of collision with the environment and with themselves along the path. At the same time, programmers often try to shape a path to be reasonably short in order to achieve a shorter motion duration. Finally, the via points must be reachable by the robot. Although this may sound trivial at first, anyone who has spent time on robot programming has likely faced situations where the robot is not able to follow the desired path because of its joints’ limitations or associated so-called kinematic singularities.

As cost-saving measures shrink the size of robot cells, programming collision-free, reachable, and efficient transfer motions becomes more challenging and time consuming. In view of this, the recently introduced collision-free path planning feature in ABB RobotStudio allows programmers to generate an efficient path in seconds by simply selecting start and goal targets, as well as robot speed, and then clicking the “create” button. In addition to reducing programming time from several minutes to a few seconds, the resulting path possesses the following advantages:

• It is generated in ABB RAPID Move commands, allowing it to be easily integrated in ABB RAPID programs.

• Regardless of the size or the shape of the obstacles or robot attachments, the nominal path is guaranteed to be collision-free.

• Thanks to the fact that it is optimized for the robot’s joint spaces, the path is particularly short.

• Since it is short, the path is energy efficient.

• It is guaranteed to be reachable and free of singularities.

• As the path is extremely smooth in terms of a robot’s joint space, it contributes to improved motion duration, reduced energy consumption and reduced stress on robot mechanics.

The last of the above advantages is achieved thanks to the automatic zone parameterization feature of the collision-free path planner. In other words, if a robot is not forced to stop at each via point and instead take a shortcut, its movement path can be traversed more quickly. Shortcuts are defined by the zone parameter for a given target, which specifies, for instance, the maximum distance that a robot’s Tool Center Point (TCP) can deviate from a target. With a larger zone parameter, the path can become smoother and shorter.

However, users often need to resort to trial and error to find a zone parameter that is sufficiently large but that does not lead to collisions. Furthermore, this must be done for all via points. This cumbersome process often results in users selecting a small zone for all the via points in a path, thus unnecessarily limiting the performance and smoothness of the intended motion. RobotStudio’s Automatic Path Planning completely automates this process such that the resulting path maximizes the number and size of collision-free zones. In addition, programming can be further simplified by selecting several goal targets for any given start target. In this case, a single click in RobotStudio will result in multiple collision-free paths.

Experts vs. Robots

Although there is no question that automatic path planning lowers the barrier to entry for many smaller companies and saves programming time, prospective users may wonder whether an automatically generated motion can offer the same level of performance as the motions programmed by experts. With this in mind, ABB recently conducted a user study [1] in which the performance of the transfer motions generated by the RobotStudio path planner were compared to the performance of the motions developed by robot programmers on a real-world robot station.

The user study focused on a robotic gluing cell from the automotive industry. The cell was characterized by a tight layout that makes it complicated to program the robot motion while avoiding collisions. The robot’s assignment was divided into several task-related motions (picking, placing, cleaning and gluing) and six transfer motions. After removal of its original program, the RobotStudio station selected for the study was sent to three RobotStudio programmers who had up to 23 years of experience in robot simulation.

Results

The experts were given written instructions to program the transfer motions of the start-goal target pairs, while trying to achieve good overall motion duration and minimal energy consumption with ordinary effort in optimizing the program. They were also asked to note down the

time from opening the station until finishing the programming.

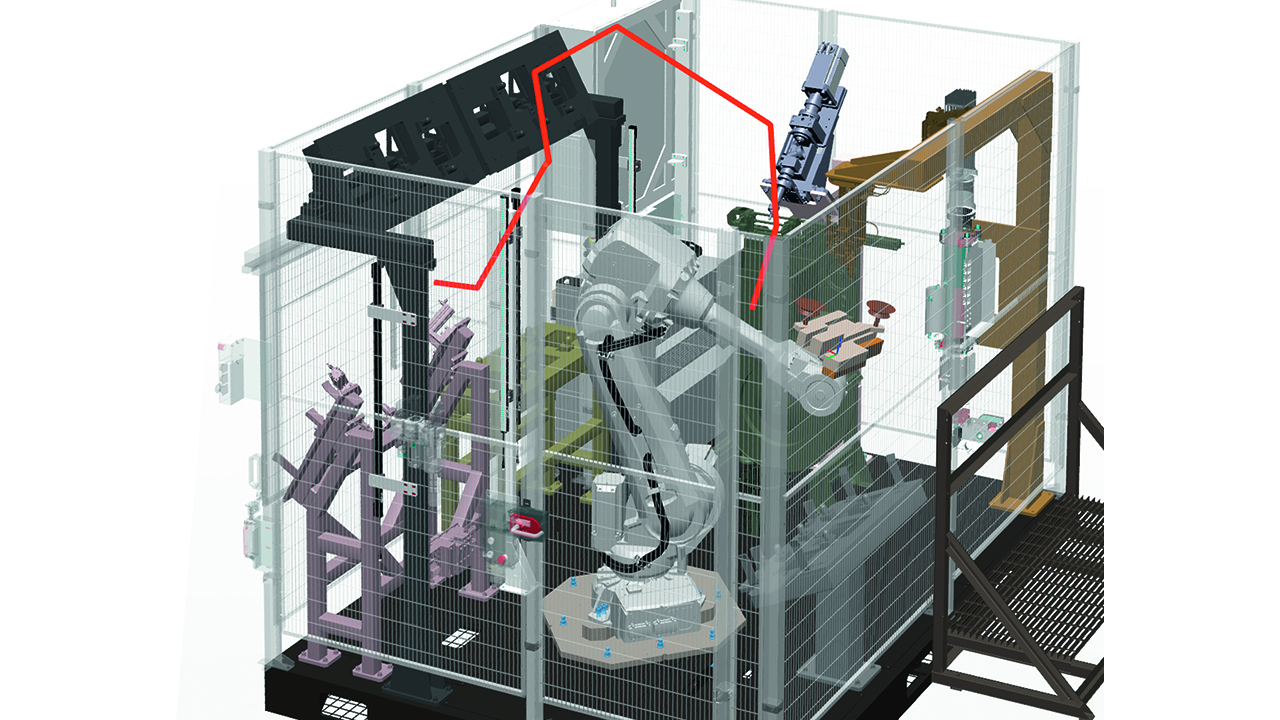

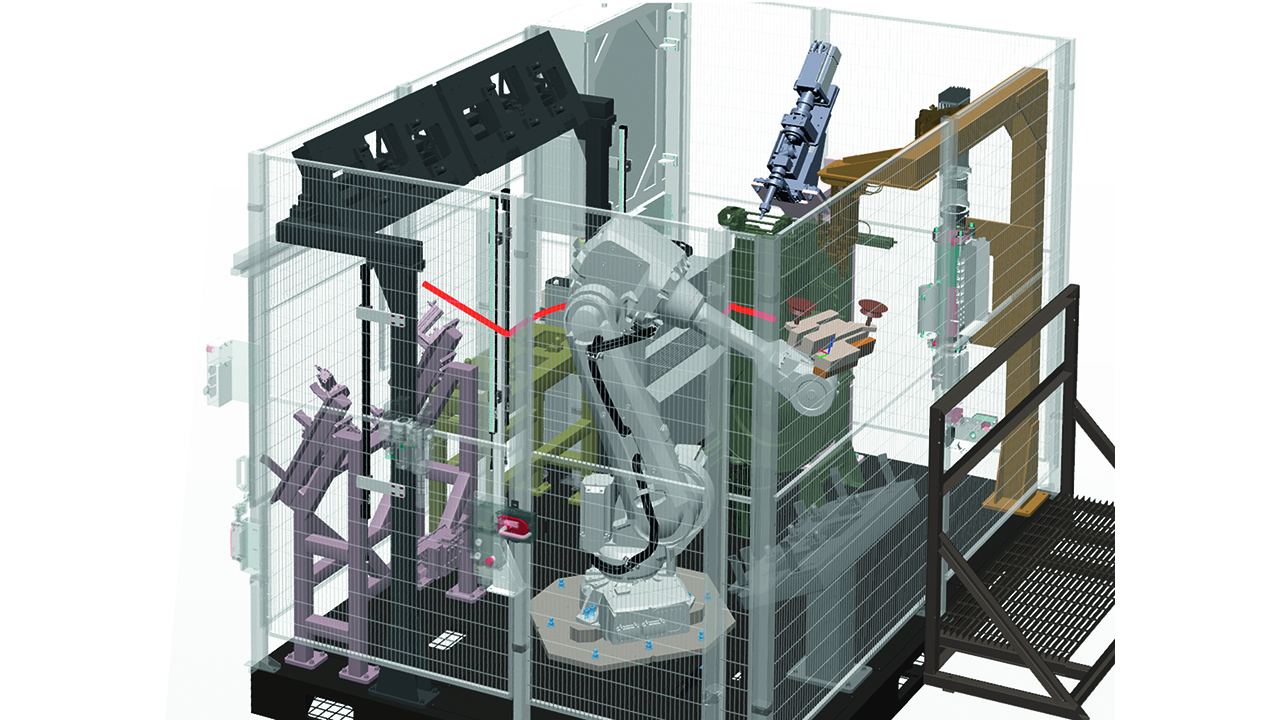

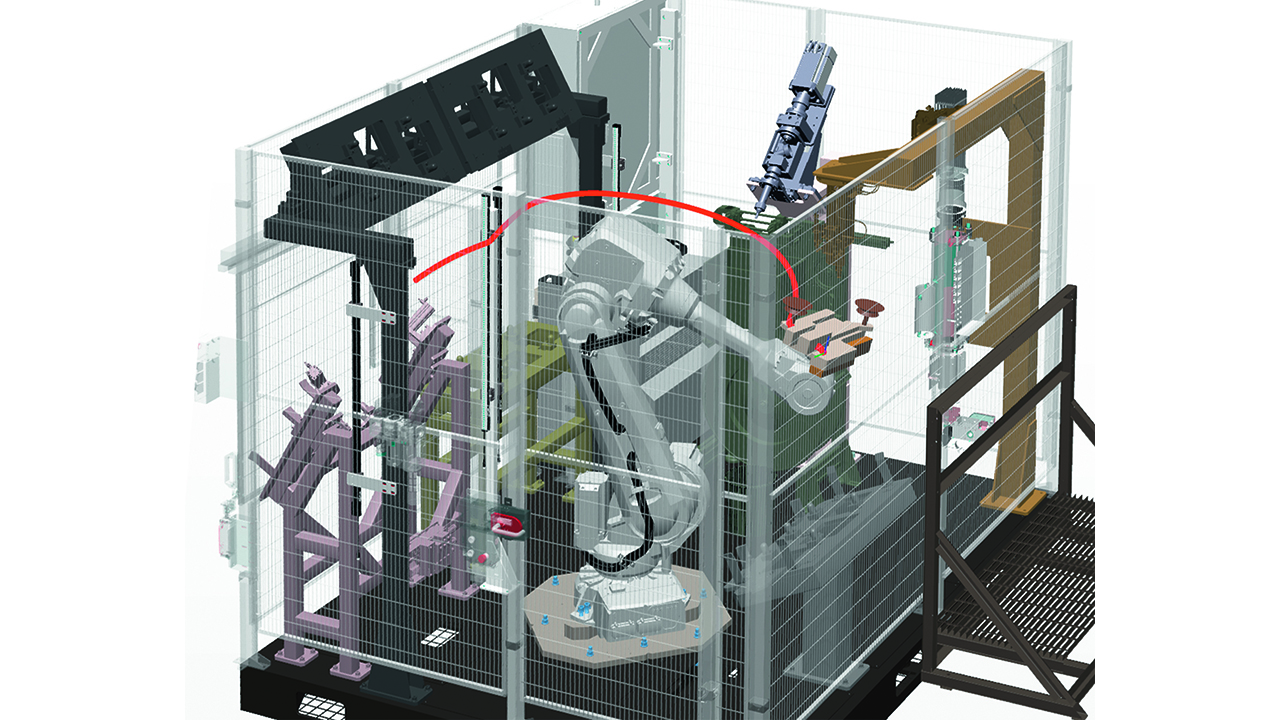

→01 shows one of the transfer motions from the original program, one from the experts, and the RobotStudio path planning motion. The red line depicts the robot’s TCP path. As expected, the expert and automatic paths are visibly shorter than that of the original program, with motion durations of 5.95 s, 3.48 s, and 2.99 s respectively for the original, expert, and RobotStudio paths. Interestingly, however, despite the seemingly shorter length of the expert path, the RobotStudio path results in a faster motion. The smoothness of the RobotStudio path is also evident in the figure.

01a Original program.

01b Expert programmer.

01c RobotStudio Automatic Path Planning

01 Comparison of robot transfer paths. Motion durations are, respectively: 5.95 s, 3.48 s, and 2.99 s.

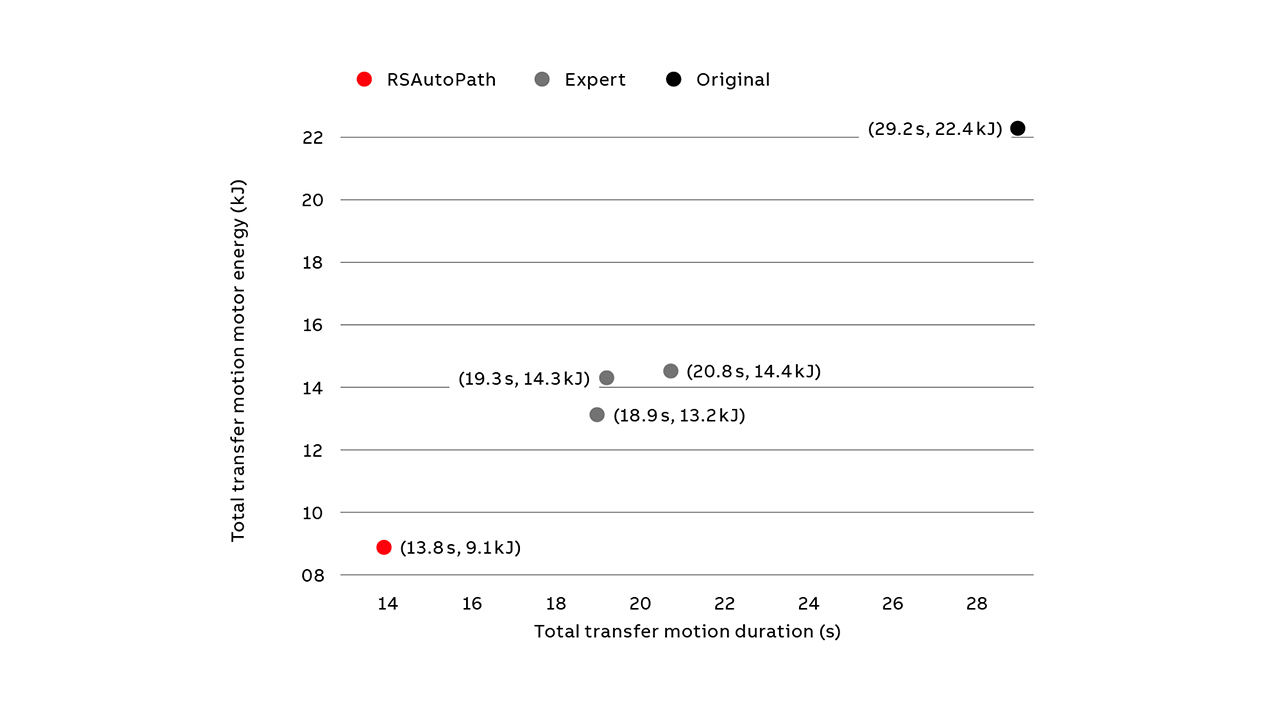

→02 depicts the overall achieved performance from each user, not only in terms of motion duration but also that of estimated energy consumed, combined for all six transfer motions. As can be seen, RobotStudio Automatic Path Planning outperforms all the users including the three experts by a wide margin in both categories. Note that all paths were programmed with the same speed parameter.

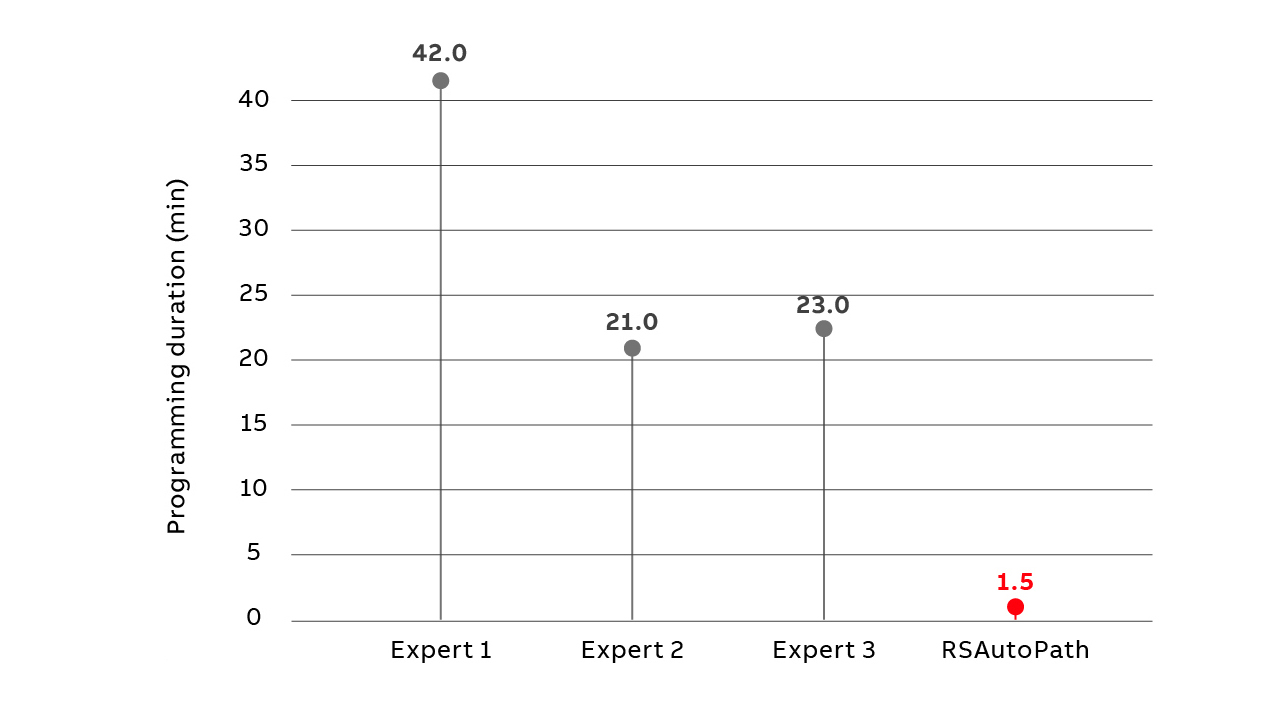

Although motion duration is often the principal performance metric of a robotics application, energy efficiency is becoming increasingly important. However, when manual programming is involved, applying a systematic approach to optimizing motion-related energy consumption, especially when a fixed speed is involved, is not practical. This is where motion planning algorithms such as RobotStudio’s offer unique value. Of course, it is possible that if experts spent more effort on optimizing a program, they would achieve higher performance. However, as shown in →03, the results of such efforts are overshadowed by RobotStudio Automatic Path Planning, which enabled the user to accomplish the task in an almost negligible 1.5 minutes, compared to 21 minutes for the fastest expert.

The 1.5 minutes achieved by RobotStudio auto programming includes converting the path to RAPID and synchronizing it with the controller (the path generation computation takes less than a second per path). Therefore, it can be argued that when it comes to transfer motion programming, experts will be able to rely on RobotStudio Automatic Path Planning in general and spend their effort on optimizing special cases, such as those for which automatic path planning fails to find a solution.

Despite having examined only one robot station and a handful of users for this article, the study’s results point to the significant potential of ABB RobotStudio’s Automatic Path Planning as a unique offering that can enable novice users to generate highly efficient robot motion programs, save considerable programming effort for experts, and reduce the runtime CO₂ emissions of robotic cells →04. This is just the beginning of an era of unmatched motion performance, greater ease of use, and new levels of robotic autonomy.

References

[1] ABB internal study. Further information available on request.