Carsten Habersetzer ABB Process Automation, Goettingen, Germany, Francisco Mendoza ABB Corporate Research Center, Ladenburg, Germany, francisco.mendoza@de.abb.com; Tilo Merlin ABB Process Automation, Frankfurt, Germany, tilo.merlin@de.abb.com

The measurement of parameters such as temperature, pressure, flow, density, concentration and level is essential for monitoring and controlling industrial processes. Moreover, increased energy and raw material costs, greater environmental awareness and higher quality standards drive operators to monitor these processes more closely than ever. Such scrutiny is not trivial when even a midscale plant can have as many as 10,000 field devices that measure and report process parameters.

Traditionally, these constellations of field devices have individually communicated with controllers and engineering tools located in a central control room via 4 to 20 mA analog current loops, commonly using HART protocol to transfer data. The introduction of fieldbuses – such as PROFIBUS, Foundation Fieldbus and Modbus – ushered in an era of digital communication for field devices, but HART retains its hold: the majority of field devices currently installed still use this champion of the industry.

A 4 to 20 mA HART loop typically consumes less than 40 mW, which is sufficient for communication with temperature, pressure, or level sensors and with some types of flow measurement, such as vortex and swirl flow meters. While they also fulfill requirements for cable length, intrinsic safety, robustness and simplicity, current loops have three major limitations:

• The transmission speed of 1,200 Baud falls far below modern expectations.

• The communication protocol is tightly linked to the physical layer and does not tolerate any other protocol in the same network, even assuming that modern protocols such as OPC UA would run over 1,200 baud on a 4 to 20 mA loop.

• HART telegrams are not routable through the IP-based networks found on upper layers of the automation pyramid and do not have any semantic, functional safety and security capabilities.

Further, modern flow, level, pressure and temperature devices, for instance, can supply diagnostic and ancillary data along with the primary measurement. Such data is not deliverable when 4 to 20 mA loops are not properly laid out and commissioned to support HART communication.

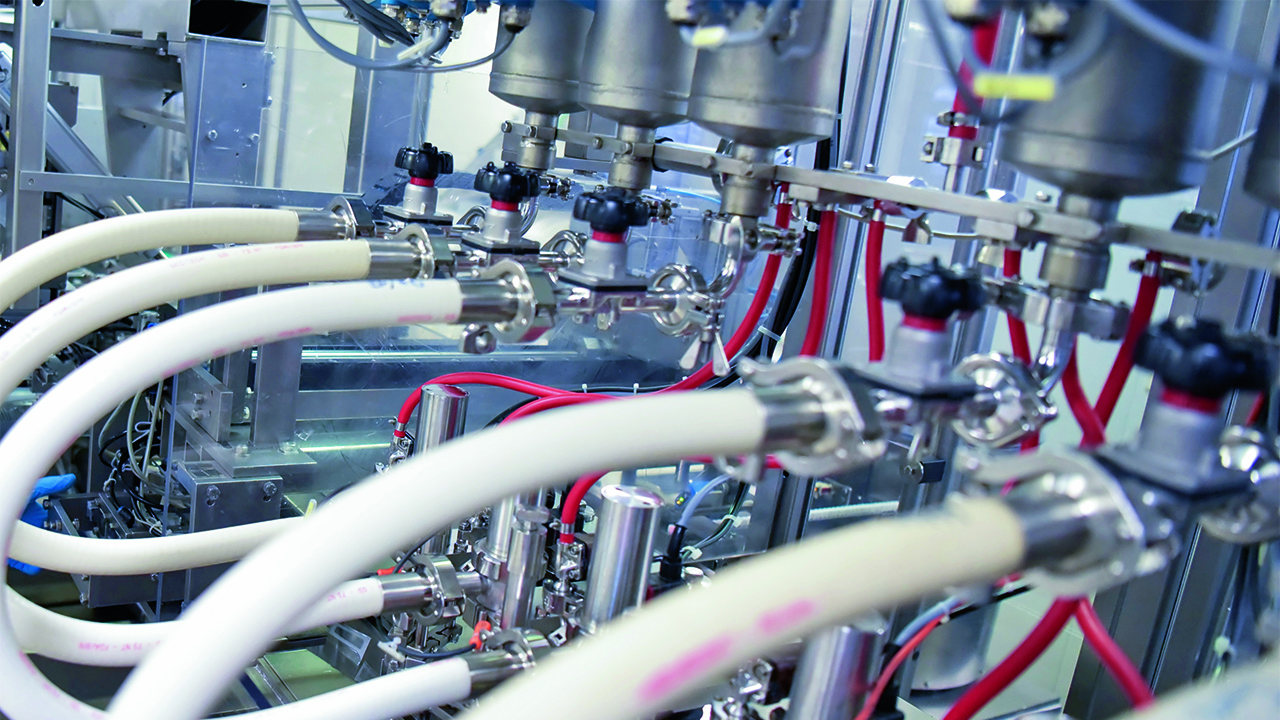

All in all, HART communication comes from an earlier time. The way forward for communications in the process industries is a new standard: Ethernet-APL. For example, for a vortex flow meter, Ethernet-APL can be used to communicate the device’s volume flow, mass flow, process temperature, totalizer values, vortex frequency and diagnostic information. Here, the traditional 4 to 20 mA output would only deliver the basic flow reading, assuming HART communication is not commissioned – which is the case in most installations in the process industry →01. The advantages of Ethernet-APL, however, extend much further – for instance, the protocol facilitates the automation of process plant design and operation and simplifies the tricky task of bringing greater intelligence into potentially explosive environments.

Ethernet-APL

Ethernet-APL represents the culmination of a decade-long journey in standardization to bring Ethernet to the field level of the process industries. Ethernet-APL is fully compatible with the IEEE 802.3 standard while satisfying specific criteria for the process industries, including intrinsic safety. Development of the protocol was backed by the leading industry standard development organizations (SDOs): FieldComm Group, ODVA, the OPC Foundation and PROFIBUS and PROFINET International. →02 summarizes how the physical layer specifications of Ethernet-APL fulfill, and in most cases exceed, HART and other technologies.

Ethernet-APL and the automation of process construction, commissioning and operation

The Industrial Internet of Things (IIoT) and Industry 4.0 are already part of everyday operations in manufacturing. Soon, these technologies will also enter the field of process automation and instrumentation. Here, for example, they will play a critical role in domain-specific concepts like the NAMUR Open Architecture (NOA) or the Open Process Automation Standards (O-PAS™) created by the Open Process Automation Forum (OPAF). These initiatives are attempting to simplify the construction, commissioning and operation of process plants. Broader use of wireless solutions, simplified field device integration and more prolific Ethernet communications are integral components of these concepts [1]. One way to advance this transformation is to agree on common communication protocols across the industry. Here, Ethernet-APL is ideal as a common communication backbone as it is – like standard Ethernet – agnostic in terms of the communication protocol and multiple protocols can, to a certain extent, run in parallel in the same network.

Useful in potentially explosive environments

One area in which Ethernet-APL is of particular interest is in potentially explosive environments. Field devices are often installed in spaces in which an explosive atmosphere may arise. Any equipment installed in these locations – and external equipment connected via cable to it – must be designed according to standards such as IEC 60079 and is subject to government regulation →03-04.

Intrinsically safe equipment is usually preferred over placing equipment in an explosion-proof housing due to the advantages of easier installation and working procedures. A device or cable is then simply classed as “safe in itself.” The key to avoiding hot surface temperatures that might initiate an explosion in these environments is a strict power limitation for any signal cable entering a relevant zone, in combination with a low-power design for the equipment itself. As it is standard practice for field instruments to comply with intrinsic safety regulations, it is also standard practice to limit their required current and voltage levels. This restriction makes it impossible to use traditional technologies, such as standard industrial Ethernet.

Ethernet-APL provides the solution because its underlying 2-wire intrinsically safe Ethernet (2-WISE) concept [2] limits voltage and current going to the field device. There is also electronic circuitry at each device input and output that prevents ignition levels of electrical energy from reaching the connector. These attributes allow the installation of Ethernet-APL devices in even the very most hazardous zones and facilitate remote service assistance in the event of process or device issues. Moreover, the power levels allowed in 2-WISE let devices perform more complex computations than in the past, enabling more precise and reliable measurements and more diagnostics. Note, too, that the two-wire implementation makes field upgrades from the two-wire HART and Fieldbus possible without expensive rewiring, as would be the case with four-wire Ethernet.

Introducing Ethernet-APL into ABB vortex meters

ABB has implemented Ethernet-APL into its FSx430 and FSx450 vortex/swirl flowmeters. This exercise was helped by the company’s long experience in industrial communication and collaboration with internal communication and security experts as well as technology suppliers and customers.

The development is based on ABB’s successful Common Top Works platform concepts for instrumentation: 2-wire and 4-wire Common Top Works (2WCTW and 4WCTW). These platforms bundle together measurement-independent features, such as the communication interface, software, power supply, explosion protection, electromagnetic compatibility, human-machine interface (HMI) and housing.

Bluetooth meets process instrumentation

Besides Ethernet-APL, another modern communication technology in the industrial space was integrated into the FSX430 and FSX450: Bluetooth →05.

Although robustness, stability and EMC considerations still impose limitations on it, at one sweep, Bluetooth can eliminate many of the complex tools, cable adapters and specific communication drivers needed by classic field instruments. Bluetooth makes local access easy with a secure smartphone app →06. Using Bluetooth for local device access has many advantages over wired access, for instance:

• Safety: There is no need to physically access the device, which can be installed several meters above ground or between hot pipes.

• Electrostatic protection: No electrostatic discharge is created as there is no contact when using wireless communication.

• Security: Bluetooth and a smartphone offer more efficient user authentication password protection than a locally integrated display on the device.

Casting a wider net

ABB’s roadmap includes applying Ethernet-APL to other field measurements – for example, temperature and pressure – as well as further enhancements, such as using PROFIsafe to apply Ethernet-APL and PROFINET to applications requiring a functional safety integrity level (SIL) →07. ABB’s TopWorks platform paves the way for upgrading ABB’s entire field device portfolio with much less effort compared to running individual projects. Resources can then concentrate on enhancing customer value.

APL will bring Ethernet to process automation – even to its most critical areas. ABB is shaping a future of a connected industrial world and is fully committed to the vision of a network-centric architecture in automation →08. Ethernet-APL will break down the barriers between the layers of the automation pyramid and turn it into a space containing just servers holding data and functions, and clients in possession of comprehensive control, visualization and optimization capabilities.

![08 Future converged Ethernet networks in the process industry, including 4 to 20 mA brownfield devices and IIoT-enabled field devices based on Ethernet-APL and multiprotocol capabilities [3].](https://resources.news.e.abb.com/images/2024/1/29/3/Leading_the_field_m3513_08_EN.jpg)

References

[1] APL consortium, “Ethernet – To the Field.” Available: https://www.ethernet-apl.org/document/ethernet-to-the-field-whitepaper. [Accessed August 3, 2023.]

[2] IEC, International Electrotechnical Commission, “IEC 60079-47 – Explosive atmospheres – Part 47: Equipment protection by 2-wire intrinsically safe ethernet concept (2-WISE)” 2021.

[3] S. Bollmeyer and F. Mendoza, “ABB brings Ethernet-APL with OPC UA to the field,” ABB Review 03/2021, pp. 58 – 65.

Photo fig. 01: © Kalyakan/stock.adobe.com

Photo fig. 04: © industrieblick/stock.adobe.com