Alf Isaksson, ABB Corporate Research, Västerås, Sweden, alf.isaksson@se.abb.com

Thomas Gamer, ABB Corporate Research, Ladenburg, Germany, thomas.gamer@

de.abb.com

Traditionally, an autonomous system is defined as one that can – without manual intervention – change its behavior during operation in response to anticipated or unanticipated events. In 2018, ABB Review published an opinion piece that introduced a more comprehensive definition of an autonomous system and sketched out some potential application areas [1] →01-02. The article was intended to stimulate discussion around the topic. An extended version of the material was presented at a conference on the dynamics of chemical processes (IFAC Dycops 2019) and subsequently published as a journal article in 2020 [2].

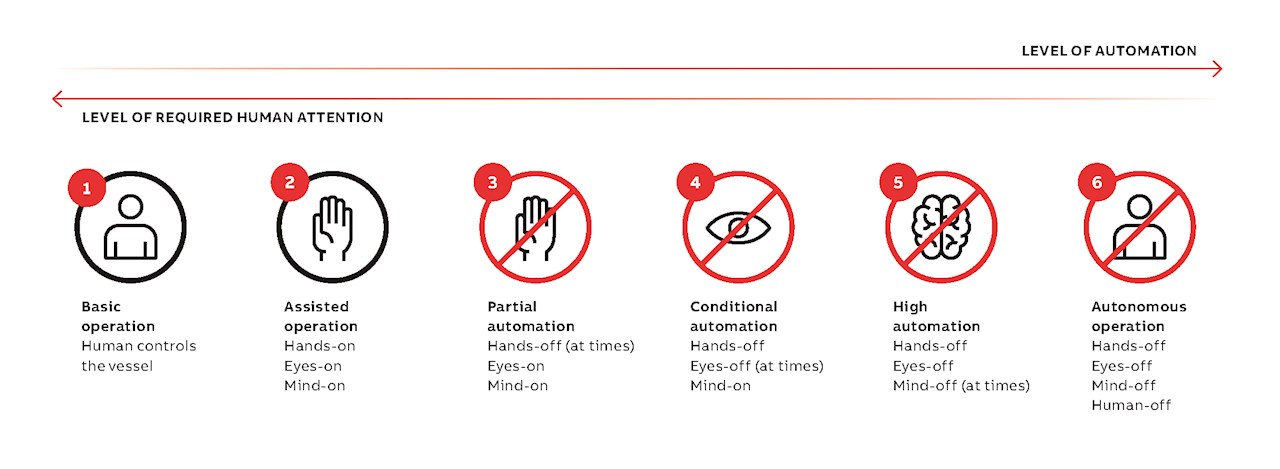

Additionally, the Industry 4.0 community has picked up on the idea and has published, for example, the autonomy levels proposed by ABB [3]. The work was inspired by the already ongoing development of self-driving automobiles and introduced a first taxonomy to describe industrial autonomy in a similar way – ie, with levels ranging from 0 to 5 →03. The ABB Review article observed that, for ABB, autonomy would first appear in applications similar to self-driving automobiles, such as mobile robotics, mining vehicles and machines, ships, cranes, etc. Potential implementations from the mining and marine sectors were described. The conference presentation and journal paper took the discussion further by reflecting on how autonomy might enter the process automation arena.

Now, five years after the first ABB Review publication, may be a good time to reflect on what has happened since in this technical area.

Autonomy in mining and marine

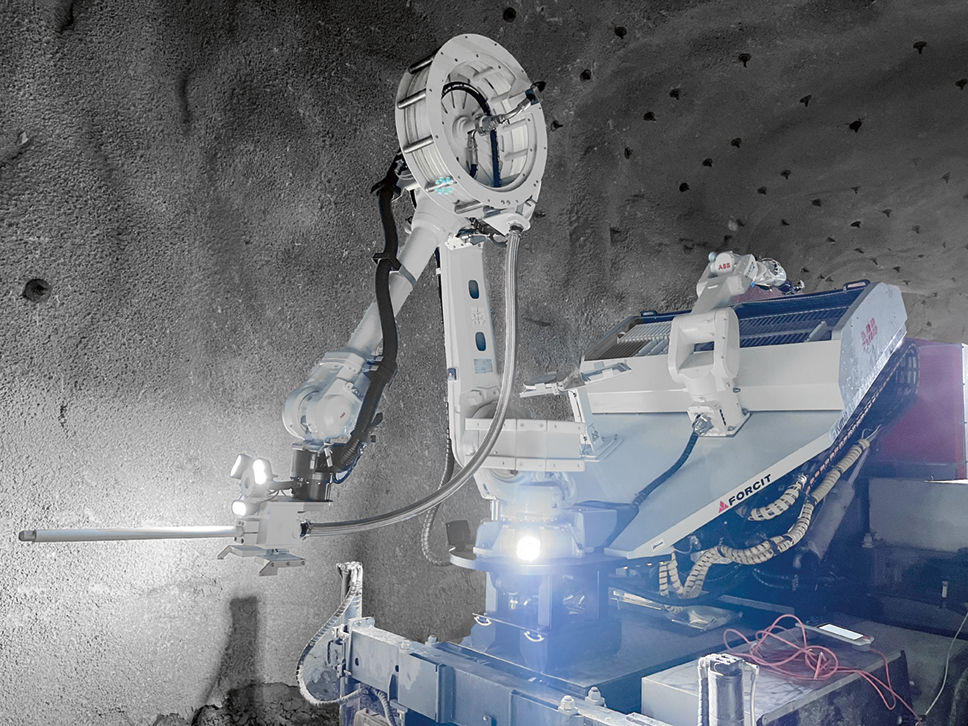

For the process automation discussed here, mining and marine are still the leading candidate application fields. For example, the 2018 ABB Review article mentioned the possibility of a robot autonomously placing explosives in predrilled holes in an underground mine. Such a charging robot has now been field-tested twice in a Swedish underground mine and a third test is underway →04.

![03 Proposed taxonomy of autonomy levels for industrial systems [2].](https://resources.news.e.abb.com/images/2024/5/8/0/4204_e_EN.jpg)

Since much of the safety benefit lies in removing personnel from underground operations, ABB also produced a remote operator station. This station, which has been delivered to multiple customers, interfaces to both ABB and third-party applications. This universality eliminates the inconvenience of multiple operator interfaces from multiple vendors, each with their own look and feel.

Outside of ABB, suppliers of mining vehicles and machines are taking great strides towards equipment autonomy. For example, at the start of 2023, Epiroc (a Swedish manufacturer of mining and infrastructure equipment) announced the conversion of 96 haul trucks to driverless operation at the Roy Hill mine in Western -Australia [4].

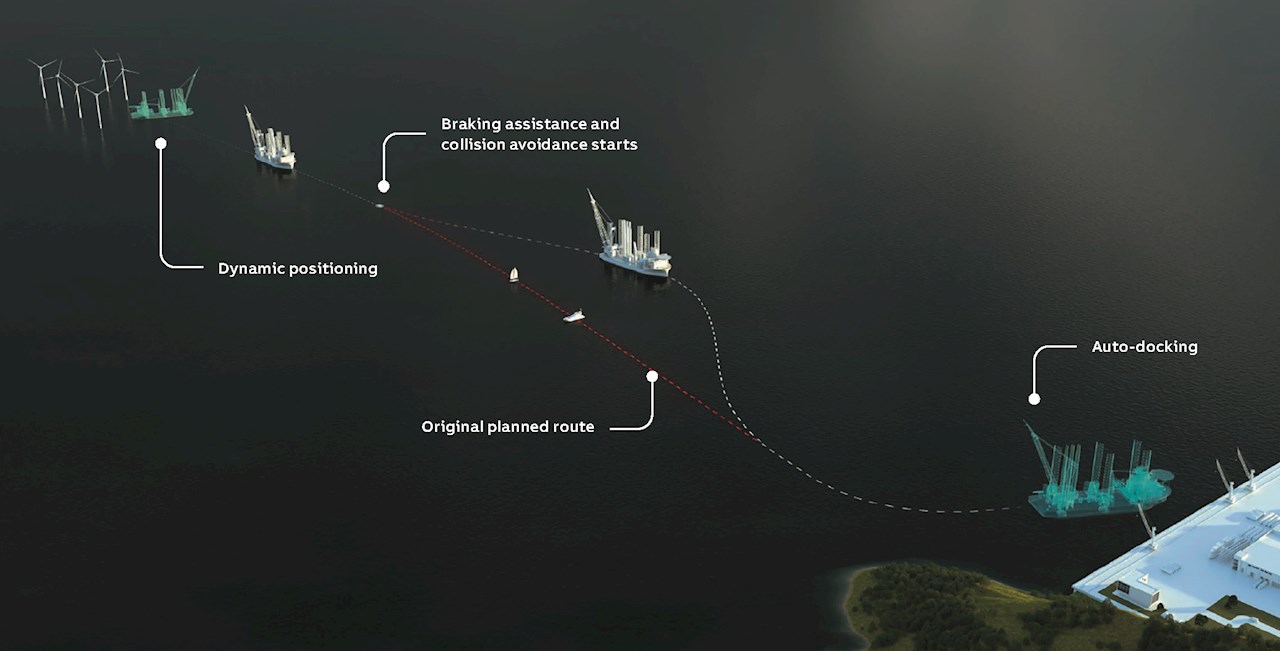

There has also been significant progress in shipping. Five years ago, ABB piloted ABB Ability™ Marine Pilot Vision, which provides a ship’s captain and crew with situational awareness based on multiple sensor sources such as radar, lidar and visual cameras. Since then, ABB has developed a collision avoidance system that utilizes image classification and tracking of other sea vessels (and other obstacles) to follow a new, collision-free path if a hazard is detected →05. The solution was implemented and successfully field-tested on a tugboat in the port of Singapore [5]. ABB has also developed algorithms for autonomous docking but these are yet to be tested live →06.

ABB had a strong influence on the autonomy levels published by the global One Sea Association (an influential non-profit global alliance of leading commercial manufacturers, integrators and operators of maritime technology) [6] →07. Bearing in mind the degree of manual attention needed for a ship’s operation, the autonomy levels in the association’s document are expressed pedagogically in terms of eyes-on or eyes-off, hands-on or hands-off, etc.

Progress in other fields

Even though ABB’s initial publications drew attention to the relevance of autonomy levels for the process industry, it was still surprising how rapidly customer interest arose in that area. For example, even by 2020, the Norwegian company Equinor had announced plans to build an unmanned oil and gas platform in the Krafla field in the North Sea. Since then, ABB has completed a project on “one button start-up” for Equinor’s gas field Aasta Hansteen in the Norwegian Sea, 300 km from land [7]. This installation saves about 5,000 operator clicks during start-up and reduces the start-up time by up to 10 hours. Note that the key here was to automate the knowledge acquired by the supplier and customer during many years of operating oil and gas platforms.

ABB’s Augmented Operator

Recently, ABB conducted a research project called Augmented Operator aimed at raising the level of autonomy in industrial operations by training artificial intelligence (AI) on past operator actions. The workflow for supporting the operator with anomaly detection, for example, is depicted in →08 [8]. Project results have been taken over into product development and presented at the ARC Advisory Group Forum 2023 [9]. In that same year, ABB started a related research project with the goal to use AI to further reduce manual operator interventions. The ambition here is to handle different operating scenarios and, with multiple autonomous agents, control larger process sections or the entire plant autonomously.

![08 The Augmented Operator workflow [8].](https://resources.news.e.abb.com/images/2024/5/8/0/4204_j_EN.jpg)

Overtaking self-driving automobiles

ABB considers it feasible that certain industrial use cases may reach a wide application of autonomy levels 4 or 5 earlier than self-driving automobiles, where progress appears to have slowed in recent years. Such an outcome is no surprise as autonomy in mining or process plants, for example, happens inside well-controlled, fenced-off areas and involves safety--trained personnel. Also, autonomous shipping takes place in an arguably more regulated environment than driving among the general public.

Progress since 2018?

It can be comfortably stated that there has been significant progress in industrial autonomous systems since 2018. There is a clear trend toward raising the level of autonomy in industrial situations by using a combination of AI and conventional control methods, based on different AI learning approaches, historical process data, past operator actions and first-principle process models. The higher levels of autonomy achieved will lead to substantial customer benefits such as improved safety, reduced energy use and increased productivity.

Factors such as skill shortages or the necessity to service remote locations provide further impetus to operators to embrace automation technologies that optimize the utilization of their skilled personnel. After Covid, there is also an understanding that remote working for many professionals is not only desirable and efficient but is also well supported by technology. It is important for ABB to address these rapidly evolving customer needs via the support that further improved levels of automation can offer.

To underline its commitment to driving the future of autonomous systems, ABB is sponsoring, from 2021 to 2025, a position in the Chemical Engineering department at Imperial College London (ICL). Thanks to this initiative, former ABB colleague Mehmet Mercangöz now has the job title “ABB Reader in Autonomous Industrial Systems.”

References

[1] T. Gamer, A. Isaksson, “Autonomous Systems,” ABB Review, 04/2018, pp. 08 – 11.

[2] T. Gamer et al., “The autonomous industrial plant - future of process engineering, operations and maintenance,” Journal of Process Control 88, pp. 101 – 110, 2020.

[3] Plattform Industrie 4.0, “Technology Scenario Artificial Intelligence in Industrie 4.0,” June 2019: Available: https://www.plattform-i40.de/IP/Redaktion/EN/Downloads/Publikation/AI-in-Industrie4.0.html [Accessed 8 January, 2024.]

[4] Epiroc, “Epiroc to support Roy Hill as it enters final stage of project to create world’s largest autonomous mine.” Available: https://www.epirocgroup.com/en/media/corporate-press-releases/2023/20230112-epiroc-to-support-roy-hill-as-it-enters-final-stage-of-project-to-create-world-s-largest-autonomous-mine. [Accessed December 13, 2023.]

[5] ABB “ABB and Keppel O&M verify next level of vessel autonomy with collision avoidance trials.” Available: https://new.abb.com/news/detail/94104/abb-and-keppel-om-verify-next-level-of-vessel-autonomy-with-collision-avoidance-trials. [Accessed 13 December, 2023.]

[6] One Sea Association, “Autonomous Ships – Terms of reference for rule development, White Paper.” Available: https://www.one-sea.org/documents/ [Accessed 21 December, 2023.]

[7] ABB, “ABB to deliver fast upstream start-up for Aasta Hansteen’s first gas production.” Available: https://new.abb.com/news/detail/54140/abb-to-deliver-fast-upstream-start-up-for-aasta-hansteens-first-gas-production [Accessed 21 December, 2023.]

[8] R. Tan et al., “Smooth Operation – Augmented Operator for Efficiency and Consistency,” ABB Review, 03/2022, pp. 18 – 23.

[9] Automation World, “ABB Previews its Forthcoming Autonomous Operator Technology,” April 2023. Available: https://www.automationworld.com/home/article/33002550/abb-previews-its-forthcoming-autonomous-operator-technology. [Accessed 13 December, 2023.]