Bernhard J. Primas, Arzam Kotriwala, Matthias Schloeder, ABB Corporate Research, Ladenburg, Germany, bernhard.j.primas@de.abb.com, arzam.kotriwala@de.abb.com, matthias.schloeder@de.abb.com

Global energy consumption has increased rapidly over the last century and will continue to do so [1]. On top of that, energy prices have risen significantly in recent years and are expected to remain volatile. Additionally, power grids, which previously evolved gradually, are now changing rapidly, with local and decentralized generation and ever more dynamic renewable resources posing grid stability challenges →01. An EMS is a vital tool for addressing these issues.

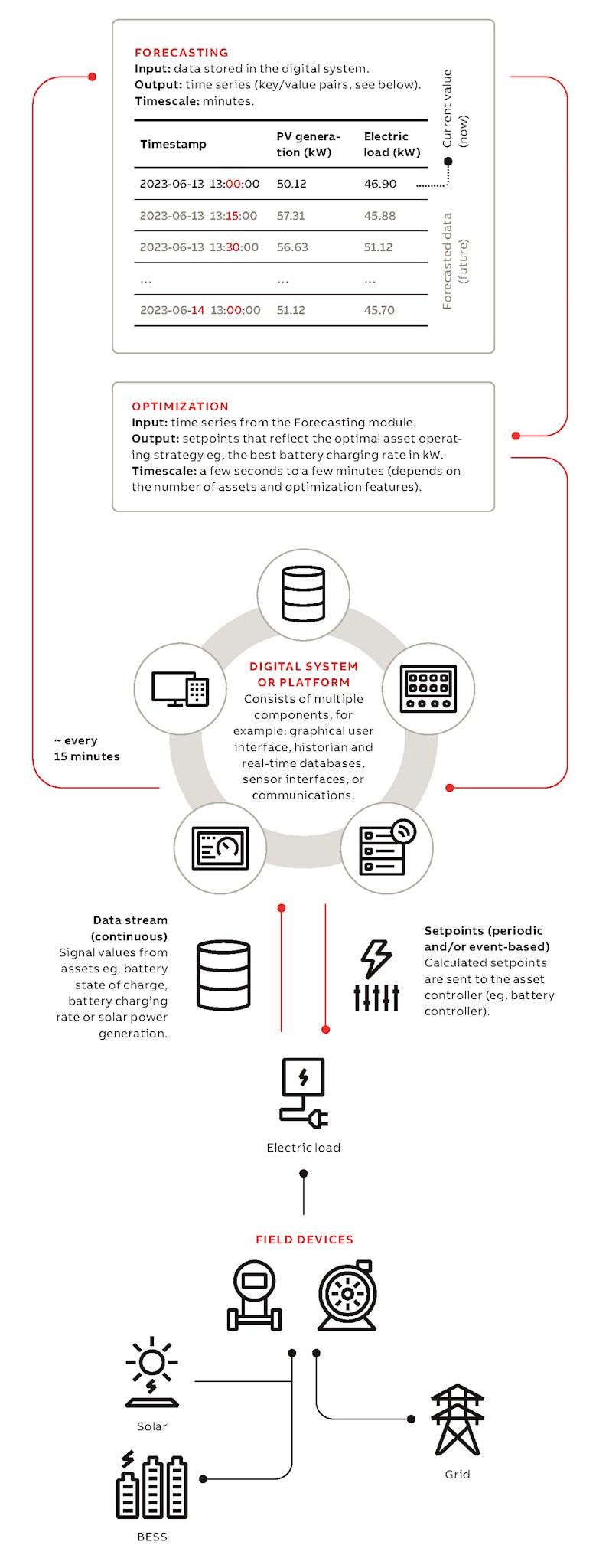

An EMS is designed to monitor, control and optimize the performance of energy consumers, generators and storage –such as a battery energy storage system (BESS) – within an organization. An EMS can be considered to be a framework consisting of various components, modules and processes. Two important functional ingredients for optimal energy management are forecasting and optimization, which ABB implemented as separate modules and are the subject of the discussion in this article →02. These two modules execute regularly (a typical execution frequency is every 15 minutes) with the forecasting module run first and its results input to the optimization module.

A forecast for the next 24 hours, for example, generates data, usually in the form of a time series, that could include expected photovoltaic (PV) generation or electricity demand of different loads.

After forecasting, the optimal asset operation strategies up to the forecasting horizon are calculated based on the forecast time series and site parameters. These strategies are applied until the next timestamp (eg, in 15 minutes). For example, the best vehicle battery charging strategy for the next 15 minutes would be applied, taking into account the renewable energy generation forecast, the energy needed to charge the vehicles and the current energy price profile. Both modules need a continuous data stream from the field as input for their algorithms.

The forecasting and optimization steps contribute the most toward minimizing energy costs. The approach ABB has chosen for these modules scales exceptionally well as it can optimize a very large number of assets simultaneously, covering all scalability requirements. Further, the optimization is performed in a global manner, ie, asset groups are not considered in isolation from each other but simultaneously as a whole.

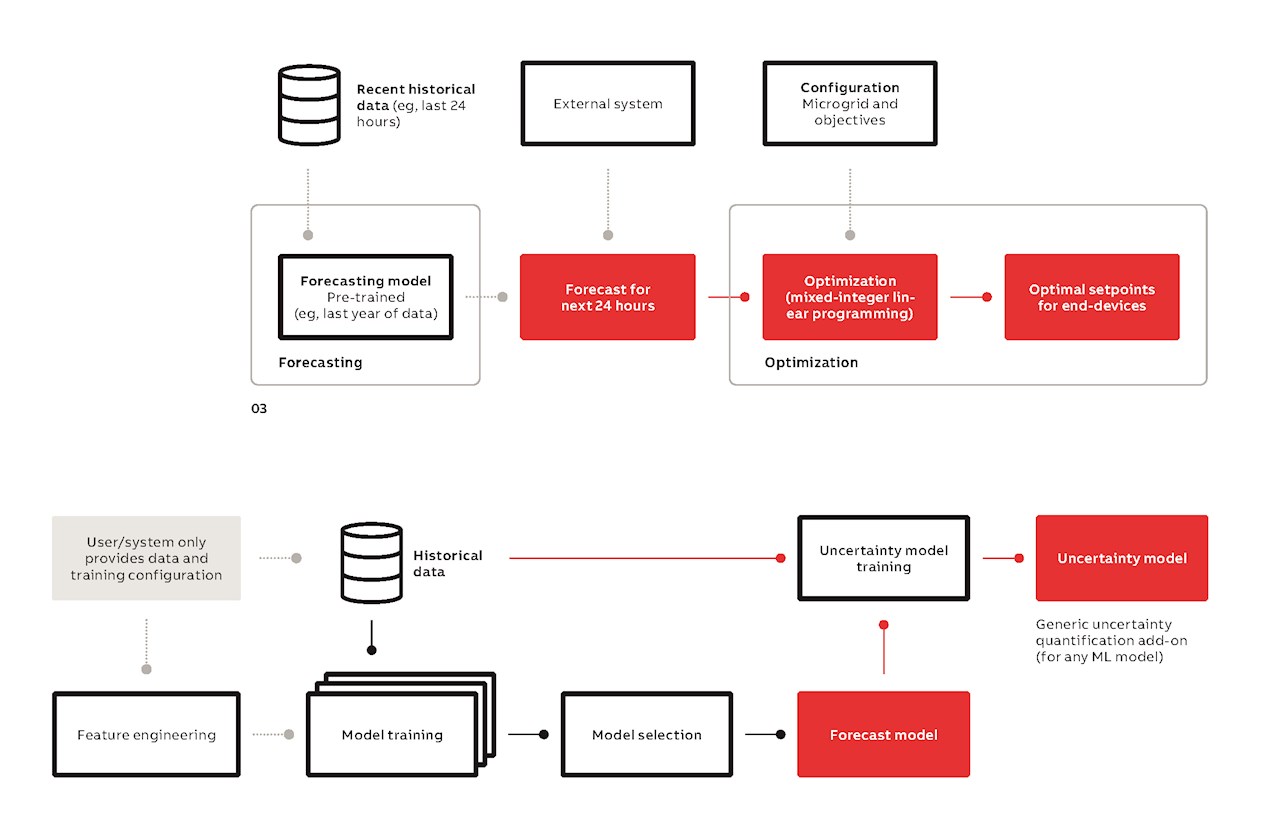

ABB’s core EMS algorithm includes AI-based generation of forecasts for the production and consumption of power, as well as mathematical optimization of setpoints →03. The lightweight solution requires only a limited number of configuration parameters but guarantees a sufficient quality of physical asset modeling.

Forecasting – how it works

Forecasting is an essential component of an EMS because being able to forecast, for example, a peak in load demand for a few hours in a day enables the system to optimize energy use and storage accordingly, thus reducing costs.

ABB developed a generic forecasting module based on automated machine learning (AutoML). AutoML algorithms and techniques improve the efficiency and accuracy of finding the most appropriate machine learning (ML) model and its parameters by automating the search. This automation includes data preparation, feature engineering, hyperparameter tuning, model selection and evaluation steps →04.

The AutoML solution is tailored for sequential or time-series data. The module performs feature engineering relating to lags, seasonality, transformations, trends, etc. that enriches time-series data. Concerning energy management, an important requirement and attribute of ABB’s forecasting solution is that it produces models that output sequence forecasts. For example, at the time of inference, the electrical load values of the past few hours (eg, 12 hours), when provided to the ML model, would generate a forecast of the electrical load over the next few hours (eg, 24 hours) at an even sample rate (eg, every 15 mins).

The forecasting module covers renewable energy generation and consumption and various electrical loads (eg, lighting or air conditioning), but the generic nature of the approach means it can, given sufficient training data, also be used to train models for other continuous quantities, such as the thermal load of a building or industrial process.

Handling forecast uncertainty

Forecasts of energy consumption and load are beneficial, but energy management can profit further from anticipating likely deviations from the forecast values. For this reason, ABB has incorporated automated training of a generic uncertainty quantification model into the forecasting module →05. Regardless of which ML technique is chosen as the best-performing by AutoML, an independent post-hoc uncertainty quantification model is created. Uncertainty quantification provides forecast intervals comprised of upper and lower bounds that should contain the true value of the load with a certain probability. Such uncertainty quantification conveys how reliable and trustworthy a forecast is. For example, narrower intervals can indicate that the machine learning algorithm is more confident in its forecasts.

Mathematical optimization

Once the forecasting module has decided what is likely to happen to energy generation and consumption over the given time horizon, it is up to the optimization module to determine the strategy that will best suit the energy targets.

Besides static data, eg, the network topology or various asset parameters, there are also flexibilities that involve active decisions – eg, the battery charging/discharging strategy. This dynamic environment means that multiple – perhaps even infinitely many – possible strategies exist, all of which are physically valid. Because the strategy chosen can have a significant financial and/or environmental impact, the task is to find a physically feasible solution that satisfies all user requirements and minimizes costs. Mathematical optimization is an excellent way to determine such a solution strategy.

Mathematical optimization requires multiple inputs, such as the technical properties of the assets (maximum battery charging rate, battery state of charge, etc.), their interconnections, asset-wise forecasted time series for consuming and generating assets over a given time horizon (usually 24 hours) as well as grid prices for the same horizon and an optimization goal with respect to which the optimal solution shall be computed. It should be emphasized that all forecasts need not necessarily be provided by the forecasting module described above but can also originate from an external provider, thereby making the ABB solution very flexible.

Using the input information, a mathematical model is constructed that describes the evolution of the electrical network over a forecast horizon as a consequence of control decisions and the resultant costs, which one aims to minimize. The available control decisions may include a battery’s charging or discharging behavior and the activation or deactivation of a flexible load. The underlying optimal control problem is modeled as a mixed-integer linear programming (MILP) problem.

Efficient solution

For MILP problems, exact solution algorithms exist that can efficiently find global solutions – ie, best-possible strategies among all possibilities. For the optimization discussed here, depending on the size of the network and the number of binary variables involved, solution times range from a few seconds to a minute.

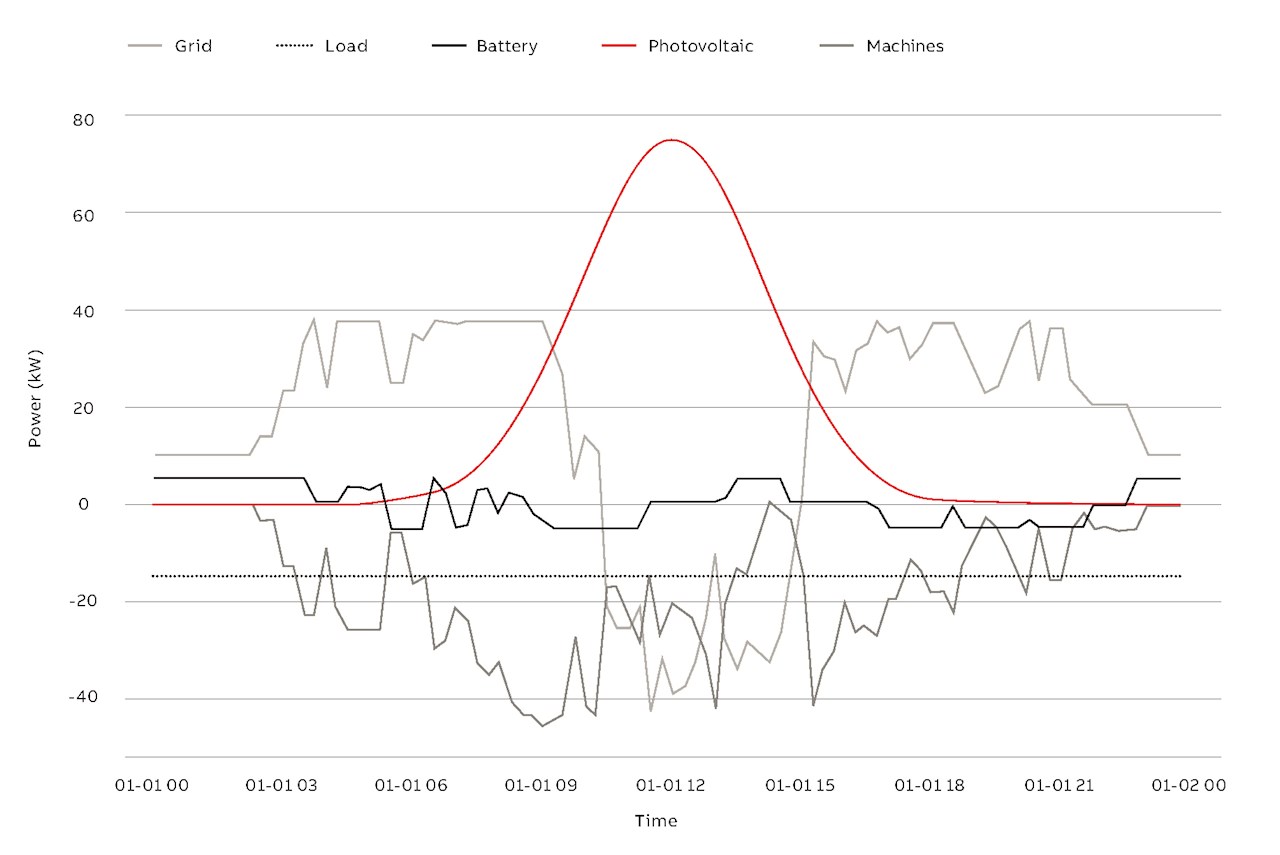

The MILP model integrates a day-ahead operation of the energy network. Thus, all information available in the next, for instance, 24 hours impacts which setpoints are sent back to the field. For example, if there is a cloudy weather forecast for the next day, the optimization algorithm may decide to keep more energy in the battery overnight as it expects less PV generation. For a sunny forecast, battery energy may be used immediately →06.

General applicability

The ABB EMS solution is general and can be used in multiple applications, ranging from commercial and residential buildings through industrial buildings to battery charging depots. In fact, any network built from supported asset types is covered, including:

- Renewable energy sources

- Electrical loads with fixed demand (ie, an electrical load with a fixed consumption pattern)

- Electrical loads that offer certain flexibilities in their usage (eg, flexible starting time and duration with a fixed overall consumption)

- Stationary battery storage systems as well as electric vehicle charging

ABB’s EMS is capable of executing various optimization strategies – depending on the particular customer’s aim. These strategies include peak shaving, energy arbitrage, load shifting and load shedding (shut-off of single loads) but also advanced objectives such as profile smoothing (minimization of fluctuations in grid or battery energy inflows or outflows) are covered. A combination of these strategies is also possible.

An easier path to a sustainable future

ABB’s EMS is a lightweight framework for automatic and optimal energy management that leverages AI-based forecasting techniques along with sophisticated mathematical optimization. The solution requires only the most essential configuration parameters, making it easy to set up and operate. Additional parameters can also be set, depending on the degree of sophistication desired by the user. With this EMS, users can reduce costs and environmental impact, paving the way to a clean, electrified and sustainable future.

Reference

[1] Statista, “Energy consumption worldwide from 2000 to 2019, with a forecast until 2050, by energy source.” Available: https://www.statista.com/statistics/222066/projected-global-energy-consumption-by-source/. [Accessed December 24, 2023.]