Andie Zhang ABB Collaborative Robotics Zürich, Switzerland andie.zhang@ch.abb.com

A new era of robotics is gaining momentum – that of collaborative robots (cobots) – robots that work safely alongside humans without the need for protective barriers and without jeopardizing speed and safety. Having introduced the world’s first collaborative robot, YuMi™, in 2015, ABB is recognized as a global leader in robots with more than 500,000 robot solutions shipped to date.

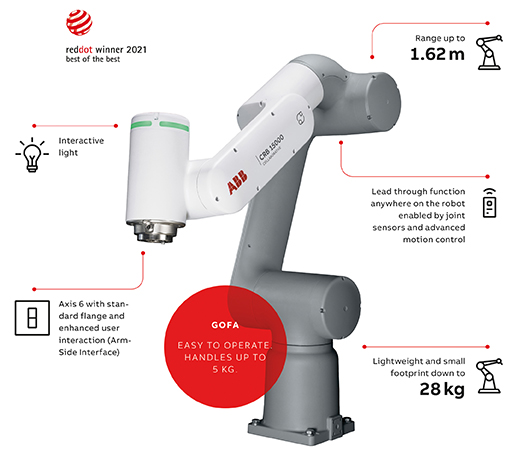

In February 2021, the newest members of ABB’s family of collaborative robots, GoFa™ and SWIFTI™ were introduced in a virtual launch event with around 10,000 live viewers [1]. GoFa handles 10 times heavier loads than YuMi, has higher maximal speed than other cobots on the market; and the integrated sensors in each of its joints ensure collaborative safety. Gofa also comes equipped with Wizard easy programming, which enables first time users to teach the robot programs within minutes. By supporting new tasks and applications, ABB’s GoFa is a game changer. In 2023 ABB launched two more variants of the GoFa CRB 15000, expanding payloads to 10 and 12 kg, and the reach up to 1.62 m as well. These new variants extends GoFa’s capabilities to be able to take on more applications, for example welding and palletizing, etc

Robotics to meet industry’s needs

For many years, industrial robots like those used in the automotive industry, have handled heavy and large payloads, yet required safety fences to keep anyone from coming too close to the robot’s fast-moving arm – a potential hazard. These robots have helped businesses lower operation and labor costs, while improving production output, product quality, and employee safety as they take on the hazardous and repetitive work of humans.

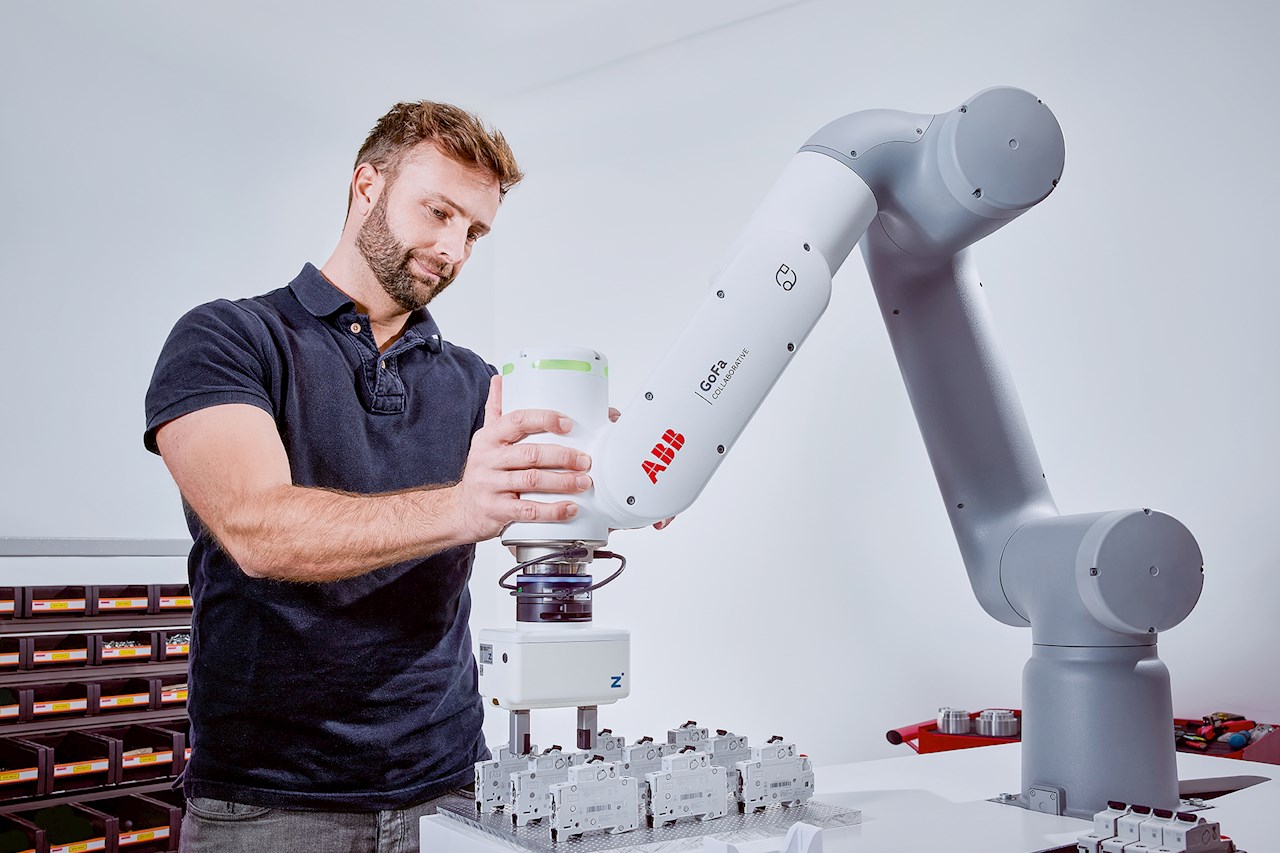

With data services, machine-learning, artificial intelligence, decreased product life cycles and differentiated products driving technology and business nowadays, ABB believes that cobots could speed up automation processes and help businesses adapt quickly to changing circumstances and respond to changing customer demand. But, this requires newly designed and engineered robots to work faster, reach further, operate more flexibly and safely alongside humans. ABB’s newest collaborative robot, GoFa, is designed and engineered with this in mind –as a helping hand for enhanced flexibility and efficiency.

New collaborative solution

Built on the success of YuMi, the new six-axis GoFa™ CRB 15000 Collaborative robot supports the growing demand for varied cobot solutions. Designed to safely work with humans and other robots, GoFa helps businesses automate processes involving heavier loads and longer reaches than previously possible.

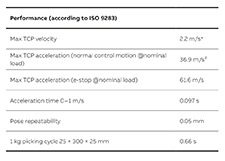

Designed to minimize its footprint and weight while maximizing speed and reach, GoFa provides heightened flexibility. Designed with a maximum speed of up to 2.2m/s and to handle payloads up to 5 kg (10 times more than one-arm YuMi), GoFa weighs only 28 kg, and has a footprint of just 165 mm² and can be mounted in any direction →01 – 02 [2,3,4]. This sleek, compact and portable cobot can be easily moved between locations as needed. And with a reach of 950 mm, GoFa outperforms other cobots that can handle up to 5 kg by approximately 12 percent →01 – 02. With a 70 percent longer reach than ABB’s YuMi single-arm robot, GoFa enables loads to be picked up and moved over greater distances, thereby helping to reduce the number of cobots that may be needed in a single space. All of these features make GoFa ideal for diverse applications, from machine tending and material handling through to picking and packaging [4]. GoFa meets industry needs – stepping in whenever and wherever needed to assist humans and robots directly and continuously.

Better performance and productivity

In addition to assisting workers with repetitive, dangerous and ergonomically challenging tasks, GoFa can support short-term process changes and be deployed quickly to perform new tasks in production lines as required, eg, when there is fluctuating demand or production batches are small. Faster than other cobots in its class →02a, GoFa can perform more operations in a set period than competing cobots. GoFa is therefore, ideal for assembly or picking and packaging tasks where items need to be quickly and accurately transferred between locations. GoFa can even be mounted easily on Automated Guided Vehicles (AGV). The author of this article finds that this ability provides users of all sizes, from SMEs to large companies, with the flexibility to quickly adapt to changing circumstances and respond instantly to changing customer demand without having to incur delays arising from having to find extra staff at short notice.

02 Important specification and performance information for GoFa CRB 15000. 02a A summary of specifications for GoFa CRB 15000.

02 Important specification and performance information for GoFa CRB 15000. 02b List of performance according to ISO 9283. * Safe collaborative speed will be lower, refer to the SafeMove configurator app for recommendation. Customers should always do a safety risk assessment of their cobot application.

GoFa is powered by OmniCore™ with its best-in-class motion control and path accuracy →02a. OmniCore features a 50 percent reduction in footprint compared with previous robot controllers and can be easily integrated with the latest digital production technologies, including a wide variety of communication protocols, fieldbuses and advanced vision systems. →02b.

A safer working partner

With GoFa’s advanced and comprehensive safety functions (certified to Category 3, PL d) risk to human workers is prevented and the need for costly and space-restricting barriers and cages is no longer required [3,4]. Safety is accomplished by factoring in the robot’s speed, the combined mass of the robot and its payload; and the ability of the robot to stop immediately upon contact. Designed with integrated intelligent torque sensors in each of its six joints, GoFa offers superior power and force-limiting performance →01 –02. Together, these features prevent the risk of injury by bringing GoFa to an immediate stop if the robot detects any contact with a human worker.

Moreover, the aluminum and plastic joints that feature a rounded geometry, have no pinch or trap points that could ensnare a human worker. The additional comprehensive set of safety functions provided by ABB’s SafeMove™, with an easy configurator app, ensure safe installation.

Because safety is crucial for all, even first-time users, ABB included a visual safety configurator on its tablet-like FlexPendant to ensure that even novice users can configure the robot safely with SafeMove. Thus, users can avoid issues such as clamping that can affect safe robot operation. Further, with an interaction status light that varies in color, depending on GoFa’s operating status, users quickly know whether the cobot is in standby, programming, operating or in stop mode →01 [2,3].

Form follows function

Despite GoFa’s superb built-in safety features, ABB knows the importance of ensuring workers feel safe and comfortable working alongside cobots. Observations of YuMi, made over five years by the author of this paper, confirm that workers feel safe working alongside the robot thanks to its unique and non-intimidating design. As with YuMi, GoFa was designed with the user at the forefront, using a combination of technological and physical features to make the new cobots approachable and easy to use.

GoFa employs slim, straight arms that give the cobot a user-friendly, yet strong appearance, while the advanced use of color, material and finish gives GoFa a modern, sleek look. Its simple arm-side interface (ASI) design with two buttons and light ring resembles the easy-to-use interfaces of consumer products. Gofa is therefore more accessible even for first-time robot users who are more accustomed to consumer technology than to industrial machinery.

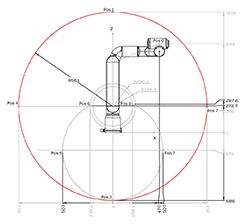

03 GoFa’s working range is depicted. 03a The working range of the robot arm is shown from the side view.

03 GoFa’s working range is depicted. 03b Gofa’s working range makes it useful in diverse settings such as the example shown here.

Award-winning design

Safe, approachable and appealing, GoFa stands out. In 2021, ABB’s GoFa cobot was awarded the prestigious Red Dot Best of the Best Design Award in recognition of its unique design concept, to make the new robot appealing and accessible to users [5].

With the jury assessing thousands of entries every year, Red Dot’s “Best of the Best” award is for groundbreaking design and is the highest award in the competition, reserved for the most aesthetically appealing, functional, smart or innovative design.

Sami Atiya, President of ABB’s Robotics & Discrete Automation Business Area said “Making robots more approachable, easier to use and more intuitive is key to our vision to make robots as familiar in the workplace as a laptop is today.” He added, “GoFa is a gamechanger, reinforcing the importance of good industrial design to make it easier for more people to work with robots. Creating an approachable design will ensure robots are adopted across a range of workplaces outside traditional factory environments.”

Easy to set up and use

Beyond world class design, ABB provides innovative, advanced and connected solutions for all of their collaborative robots and GoFa is no exception. With all functions implemented on the intuitive, graphical, tablet-like FlexPendant, eg, SafeMove configurator, GoFa is a snap to set up, configure and operate →04. Installation includes a start-up package that provides ABB Ability™ condition monitoring and diagnostics as well as a support hotline to access ABB’s expert technical assistance.

The Wizard easy programming feature, possessed by all ABB’s families of new cobots (GoFa™, SWIFTI™, single arm YuMi™) and an increasing number of industrial robots, allows novices to quickly and easily create robot programs even without the ability to code. Users can teach their robot new tasks in minutes by simply dragging and dropping graphical boxes in the app. ABB has added online tutorials and how-to videos on topics from setup and programming, through to operation and troubleshooting.

Experienced ABB robot users have not been neglected either. Wizard Skill Creator allows expert users to create their own customized blocks, known as Skills, which can be produced to control grippers or create actions for specific applications such as laboratory automation.

Existing customers appreciate that their expert ABB robot users can continue to access engineering tools, eg, RAPID programming, RobotStudio®, as they have previously without the need to learn new systems for ABB’s cobots. Overall, GoFa offers beginners and experts alike all the engineering and programming tools they need to create programs and teach their robots easily [1].

Customer value

Not surprisingly, since its launch in 2021, GoFa has received an overwhelmingly positive response from ABB’s customers. Customers especially like the Wizard easy programming feature. Further, both novice and experienced customers appreciate the user-friendly experience, akin to that of tablets, resulting from having functions implemented as apps on the FlexPendant.

Overall, GoFa™ CRB 15000 Collaborative Robot is ushering in a new era of collaborative robots – approachable, fast and intelligent; this cobot reaches further than ever, yet stops in milliseconds upon contact, exactly what workers need from a helping hand.

References

[1] ABB Press Release, “ABB launches GoFa™ higher payload cobot for collaborative tasks up to 5kg”, February 24, 2021, Available: https://new.abb.com/news/detail/74323/prsrl-abb-launches-gofa-higher-payload-cobot-for-collaborative-tasks-up-to-5kg

[2] ABB Product Specifications “GoFa CRB 15000 Technical Data”, Available: https://search.abb.com/library/Download.aspx?DocumentID=9AKK107991A8564&LanguageCode=en&DocumentPartId=&Action-=Launch

[3] M. Mustard, “A new class of coworkers”, ABB Review 3/2021, pp. 46 – 51.

[4] ABB Robotics Solutions, “Collaborative Robotics Portfolio”, 2021, pp. 1 – 16. Available: https://library.e.abb.com/public/147f234ec5fd-4573b7555a1c1-bf64159/-180221%-20Cobot%20-family_Brochure_-digital.pdf[5] ABB Press Release, “ABB’s new GoFa Cobot wins prestigious Best of the Best Red Dot award”, April 12, 2021, Available:https://new.abb.com/news/detail/76652/prsrl-abbs-new-gofa-cobot-wins-prestigious-best-of-the-best-red-dot-award