Today marks the 55th anniversary of Earth Day. Beginning as a national day of protest in the US, Earth Day has grown to a global event for environmental protection recognized by individuals, local organizations, governments, and corporations alike.

Much has changed in the last 55 years. Perhaps the most notable change since 1970 has been technological advancements and, in particular, digitalization. This year’s theme for Earth Day is Our Power, Our Planet™, emphasizing the importance of clean power and energy efficiency to the climate movement. As an electrification and automation technology leader, ABB is proud to celebrate Earth Day with the announcement of new, cutting-edge software capabilities that will help industry protect the planet:

ABB Ability™ Energy Management System (EMS) enabled with Artificial Intelligence / Machine Learning (AI/ML)

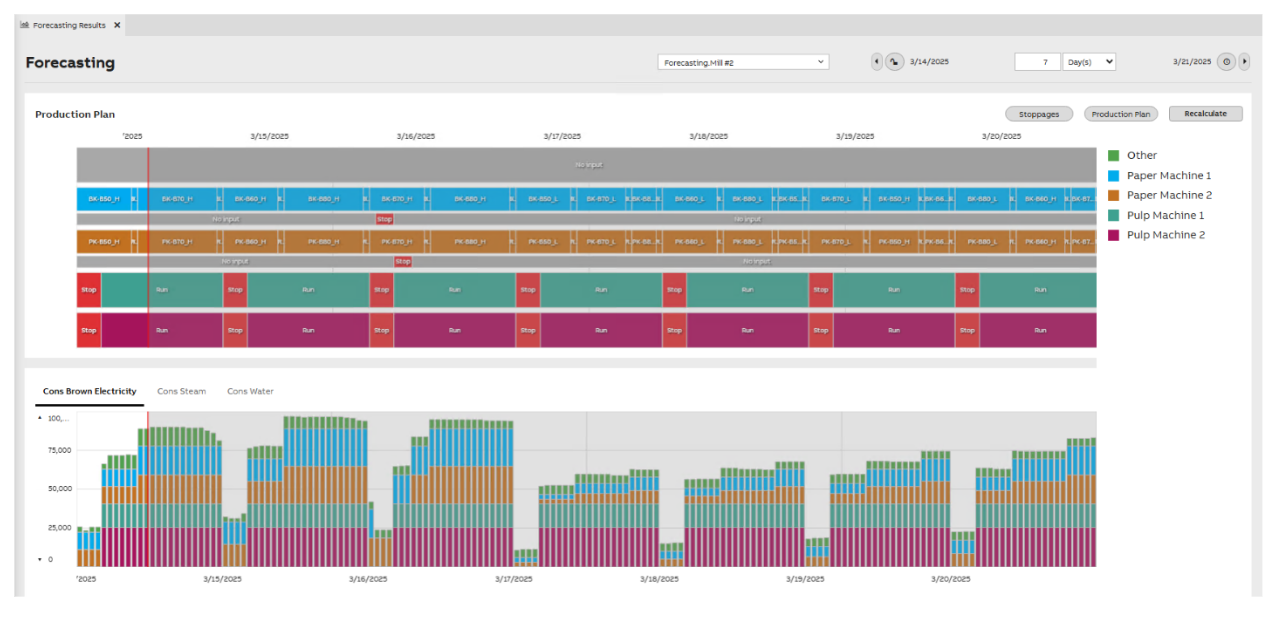

EMS can predict the energy consumption of an entire industrial plant and its process areas, allowing our industrial customers to save money by more efficiently managing their energy procurement & planning. Traditionally, we have done this using a plant’s production plans to forecast future energy consumption, but we would run into a challenge when a production plan was not available for certain equipment and process areas and/or if the available production plan was not detailed enough. Now, EMS uses an ML method to calculate energy consumption based on historical and/or anticipated process parameters. The ML model makes it easy to identify the hidden patterns between process parameters and energy consumption.

EMS also uses AI to detect anomalies in energy consumption behavior. Most energy monitoring solutions can alert operators when energy is being consumed out of the expected range and/or above preset energy consumption targets, and normally, this is done by manually setting the expected range for energy consumption for each piece of equipment. However, this process of manually setting thresholds is time consuming, and the presets can quickly become inaccurate when the equipment is operated in different modes that consume more or less energy. Additionally, as equipment ages, its energy efficiency changes over time, so the manual presets will have to continually be updated. Our AI anomaly detection generates the expected energy consumption range based on historical behavior and retrains itself as new data comes into the system. The range will adjust automatically as needed as the operating mode changes and the equipment ages. Thus, the EMS AI anomaly detection saves configuration time and reduces the risk of false positive alerts due to inaccurate preset consumption ranges.

To stay on top of the latest information about EMS, including success stories about EMS with AI/ML, sign up to receive email updates.