ABB Electrification’s Smart Buildings plant in Porvoo, Finland was one of the first sites to embark on a journey to net-zero emissions and more sustainable operations. Since 2021, the 71,000-sq.-ft. facility has significantly reduced energy use and emissions, powered by a combination of data-driven decision making and innovative energy management.

The local team has taken innovative steps to use environmental conditions to its advantage. For example, ABB’s first seasonal geothermal storage system uses retrofitted air compressors to extract wasted heat energy from injection molding processes and pumps it into rock wells 1,000 feet underground, creating a reservoir of renewable energy.

“In the summer, when we don’t need to heat our facilities, energy is stored underground and saved for our harsh winters, when temperatures quickly drop down to 20-below,” explains Petri Kotilainen, site Energy Manager.

The geothermal system has reduced Porvoo’s district heat usage more than 90%, from up to 900 MWh to low single-digits. “We now use district heat only as a backup and are close to eliminating it completely,” Kotilainen adds.

The factory also produces energy through a 250 kWp free-standing photovoltaic system, which self-generates 220 MWh in solar energy per year thanks to Porvoo’s almost year-round sunshine.

Porvoo’s path to net zero has been powered by a combination of data-driven decision making and automation. More than 100 energy measurement points are connected to the ABB Ability™ Energy Management System, which analyzes energy consumption and costs in real-time.

“Capturing reliable data is crucial to driving energy efficiency,” says Josi-Pekka Roppola, site Facility Manager. “Knowing exactly where, when and how we use energy helps us decide where to invest.”

A Culture of Continuous Improvement

Collaboration has accelerated Porvoo’s success. In addition to leaning on the expertise of partners, employees’ crowdsourced ideas fuel the plant’s progressive journey. The team showcases these best practices with customers and stakeholders through interactive site tours and product demos.

“We wanted to be seen as early adopters and pioneers since the beginning, and we are,” Roppola says. “We don’t do any of this because we have to… it’s in our DNA. Our commitment to sustainability — which extends well beyond energy efficiency — sets us apart in a market that demands commitment and action.”

Beyond Emissions

Since achieving Mission to Zero status, Porvoo has come up with increasingly creative ways to operate more sustainably and protect local biodiversity, including by installing an on-site bug hotel and birdhouse community. A colony of 100,000 bees pollinates more than 1 million flowers daily and produces honey, which is given to visiting customers as a gift.

The facility’s environmental stewardship strategy also includes programs to conserve water and reduce waste. Innovative injection molding processes set aside plastic waste from production lines to convert into oil (through chemical recycling) for use by the broader plastics industry. Additionally, SAGA™ light switches and accessories made in Porvoo use ISCC PLUS-certified bio-circular, recycled material. They have earned third-party verified Environmental Product Declarations (EPDs) and are part of the ABB EcoSolutions™ product portfolio.

This ongoing work ladders up to ABB’s global circularity model to minimize waste and maximize resource efficiency at all stages of the product lifecycle.

“The story we have to tell perfectly combines what we’re doing on Mission to Zero, which naturally includes many of our own solutions, with our commitment to product circularity,” says Mia Astikainen, Sustainability Specialist. “We hope to make an even bigger impact as we continue on this journey and, hopefully, inspire others to join us.”

The Road Ahead

Looking ahead, Porvoo is focused on tracking and reducing Scope 3 emissions with its supplier network, pursuing Zero Waste to Landfill certification, and adding low carbon transportation solutions to its supply chain. The team stresses the importance of both due-diligence and agility.

“Patience is crucial,” Roppola says. “You must first understand your environment, processes, and energy resources before you can make the right decisions. And that means being prepared to do the work instead of expecting turnkey solutions.”

Importantly, the plant’s Mission to Zero journey has created a positive ripple effect. “Our enthusiasm and passion have generated a lot of positive interest and curiosity," Astikainen concludes. "We consistently hear, 'Wow, you're doing such great things. How did you do all of this?'"

Mission Possible

Five years ago, ABB turned ambition into action with the launch of Mission to Zero. To date, more than 20 facilities on four continents have achieved Mission to Zero status through a combination of smart building solutions, renewable energy, electrification, and resource-efficient tools and technologies from both ABB and third parties.

Porvoo’s Mission to Zero by the numbers: an estimated 636 tons of CO2e emissions are reduced annually compared to 2019 baseline; the site has also achieved a 30% increase in energy efficiency overall and a 50% reduction in mixed plastic waste. The site has improved its recycling rate by 20%, reflecting an increase in the amount of materials recycled or recovered from waste and the inclusion of recycled materials in products.

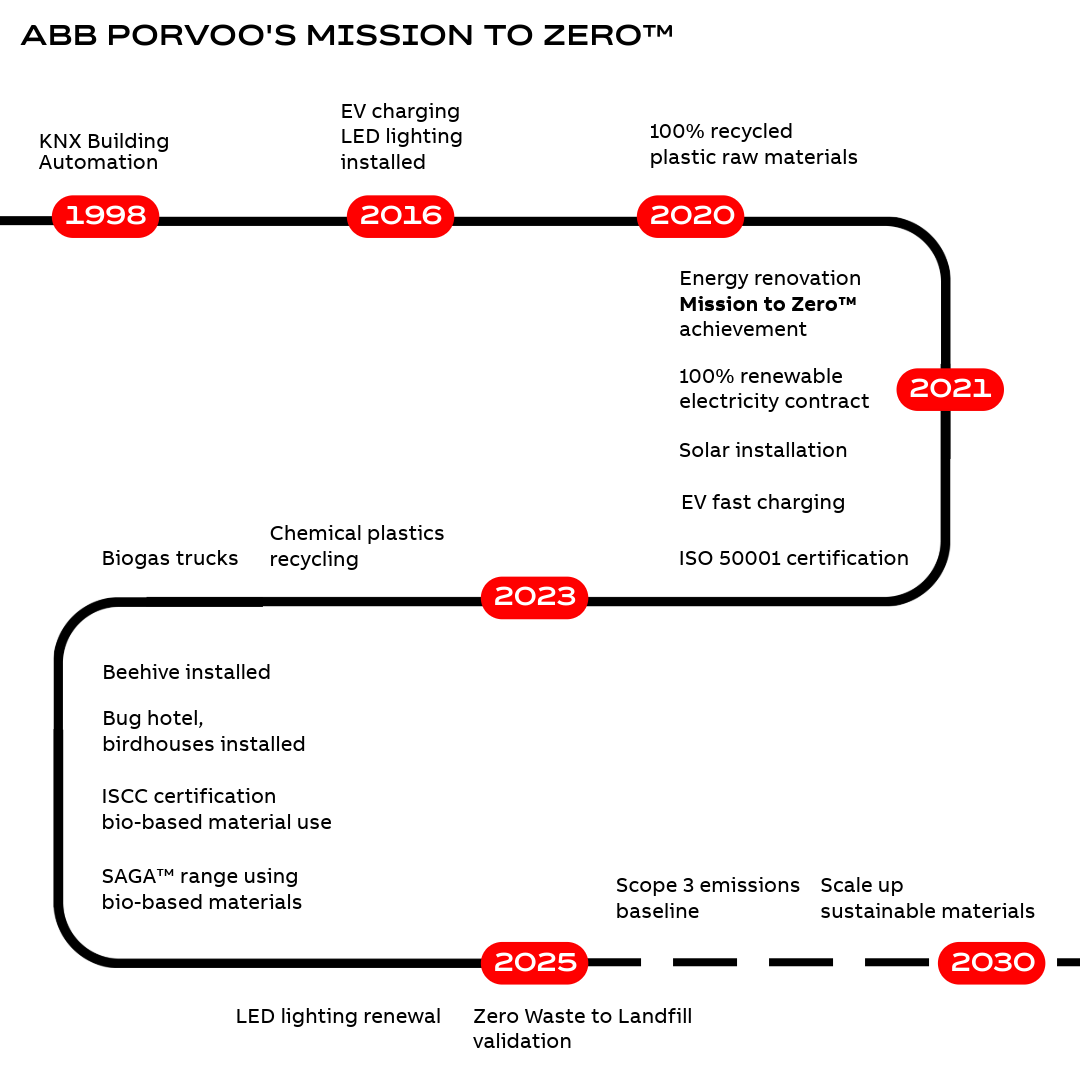

Porvoo’s Mission to Zero journey over time, including steps taken to expand environmental stewardship and further reduce emissions since achieving Mission to Zero status in 2021.

This story is part of a series about progress made at our first Mission to Zero™ sites around the world. Mission to Zero is our journey to reach net-zero emissions and more sustainable operations. Bringing together technologies using ABB digital solutions and renewable energy, we’re increasing efficiency and reducing emissions at our sites. To learn more, visit our webpage.