Green hydrogen production relies on efficient electrolysis systems to split water into hydrogen and oxygen. One of the key challenges in scaling up this technology is managing electrical losses that can occur due to stray currents, also known as shunt currents. These unwanted currents can reduce overall alkaline system efficiency, leading to higher operational costs.

To address this issue, Stargate Hydrogen, ABB, and LUT University have formed a research partnership to study shunt currents in an alkaline electrolysis medium-voltage system (medium-voltage typically refers to voltages up to 1500 VDC). By analyzing the effects of stray currents in a medium-voltage alkaline electrolysis setup, the project aims to improve efficiency and reduce costs associated with power supply components.

As of present, the study has made steady progress, and the researchers at LUT University were able to measure the individual cell voltages of a smaller set-up, comprised of two Stargate special-purpose stacks connected in series.

That is only the starting point of the study that will reach the final stage, where larger systems of up to 10 stacks will be tested while powered by ABB’s power supply.

The objective of the study

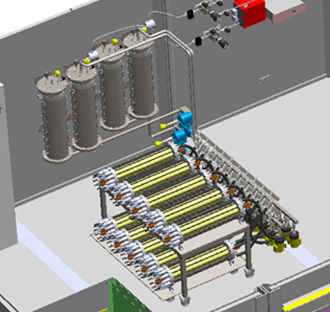

The primary goal of this study is to reduce system costs and study the connection of alkaline stacks by measuring and analyzing stray currents within the balance of plant (BoP) and electrolyzer stacks in a water electrolysis system. The research will focus on understanding how shunt currents behave, starting from a 2 stack set-up and moving up until the size of the system reaches the final 10 electrolyzer stacks with 48 cells each, identifying the impact of stray currents on current efficiency, and exploring ways to optimize system voltage levels while maintaining stable and efficient operation. To achieve these objectives, researchers will examine how electrolyte hoses connecting the stacks to manifolds influence current leakage.

The cost of power supply systems (rectifier, transformer, and switchgear) is a significant factor affecting the balance of plant cost and further cost of green hydrogen. Current handling capability is the dominating factor in the cost of power electronics needed for AC to DC rectification. The proportional cost of power electronics can be minimized by increasing the system voltage level towards the 1500 Vdc limit defined by the low voltage directive. Simultaneously, lower current level decreases the cost of other parts of the power supply system, e.g. transformer, busbars, and circuit breakers.

The electrolyzer system voltage level can be increased either by building longer stacks or connecting stacks electrically in series. However, stray currents and mechanical limitations set practical limits for the length of a single stack, and finding optimal stack length is an issue for technoeconomic optimization. Thus, serial connection of relatively short stacks is the chosen approach.

1000 V setup with ten stacks connected in series

Setup with 2 stacks to measure the cell voltage characteristics and the current efficiency of a single stack or two stacks connected in series.

Atmospheric alkaline water electrolysis test setups:

- 1) 1000 V setup with ten stacks connected in series

- 2) Setup with 2 stacks to measure the cell voltage characteristics and the current efficiency of a single stack or two stacks connected in series. The stacks are custom-built by Stargate for the project and are scaled-down versions of industrial alkaline electrolysis stacks.

The research setup and participants

The study aims to be performed, at its conclusion, in a large-scale test system comprising ten electrolyzer stacks, each with 48 cells, connected in series. The laboratory-scale stacks, equipped with cell-level voltage probes, are designed and manufactured by Stargate Hydrogen. Key parameters of the test setup include:

- System voltage: 1000 V

- Nominal current: 60 A (selected based on ABB’s industrial power converter, ACS880)

- Grounded steel piping connecting manifolds to separation tanks

- Insulating electrolyte hoses used to connect stacks to manifolds

The participating institutions and key stakeholders involved in the study are:

- Stargate Hydrogen: Rainer Küngas.

- ABB: Simo Säynevirta, Simo Vuorsalo, Matti Kauhanen.

- LUT University: Associate Professor Vesa Ruuskanen, Professor Jero Ahola, Professor Pertti Kauranen, Junior Researcher Toni Viinanen and Markku Niemelä the Research Director.

By combining expertise in electrolyzer development, power electronics, and industrial research, the team is well-positioned to generate meaningful results.

The importance of industry-academia partnerships

Collaboration between stack manufacturers, universities, and engineering companies is essential for advancing technology. These partnerships bring together theoretical knowledge, practical engineering expertise, and industrial scalability, creating a strong foundation for innovation.

By working together on this project, stakeholders can accelerate the development of efficient and economically viable electrolysis systems. Academic institutions provide the research infrastructure and expertise needed to conduct rigorous experiments, while industry partners offer the manufacturing capabilities and market insight necessary for large-scale implementation.

These collaborations reduce development time, lower costs, and improve the reliability of emerging technologies, making hydrogen production more competitive within the energy market and help turn scientific discoveries into practical solutions that benefit the entire hydrogen economy.

This partnership between Stargate Hydrogen, ABB, and LUT University highlights how collaboration drives meaningful advancements in electrolyzer technology.

Advancing electrolyzer technology

The partnership between Stargate Hydrogen, ABB, LUT University, and Aalto University is just at the beginning and is an important step towards refining water electrolysis system design. The findings from this study will be used to shape future electrolyzer development.

Results of the study

The results will be presented at the ICE2025 conference by Professor Vesa Ruuskanen in August. If you are curious to know more about the results of the full study keep your eyes open for PART 2.

ABB Motion a global leader in motors and drives, is at the core of accelerating a more productive and sustainable future. We innovate and push the boundaries of technology to contribute to energy efficient, decarbonizing and circular solutions for customers, industries and societies. With our digitally enabled drives, motors and services our customers and partners achieve better performance, safety and reliability. We deliver motor driven solutions for a wide range of applications in all industrial segments. Building on over 140 years of domain expertise in electric powertrains, our more than 22,000 employees across 100 countries learn and improve every day. abb.com/motion

Stargate Hydrogen - Stargate Hydrogen was founded in 2021 to make green hydrogen affordable for hard-to-decarbonise industries like steel, fertilisers, and chemicals. Our focus: improving electrolyser efficiency and cutting costs using novel ceramic catalysts and patented stack design. With €50M+ in funding from strong investors and IPCEI status we’re scaling production to 140 MW annually. Our customers spread across Europe, Turkey, and India. receive extensive engineering support while integrating our products into their operations. We deliver real results through efficient and scalable hydrogen solutions. Stargate Hydrogen - Electrolysers

LUT - The LUT University is an international community of over 9,000 curious minds is dedicated to addressing global challenges through science, technology, business, and social innovation. Since 1969, it has pioneered interdisciplinary solutions for clean energy, water, and air—essential resources for a sustainable future. With campuses in Lappeenranta and Lahti, and a mindset that transcends borders, the institution empowers individuals to think differently, experiment boldly, and create meaningful impact. Uteliaiden yliopisto | LUT-yliopisto