- ABB showcased its cutting-edge gearless grinding and mining solutions at the 15th anniversary edition of the International ‘Astana Mining & Metallurgy’ Congress—one of Central Asia’s premier mining events—through an innovative stand tailored to the local market

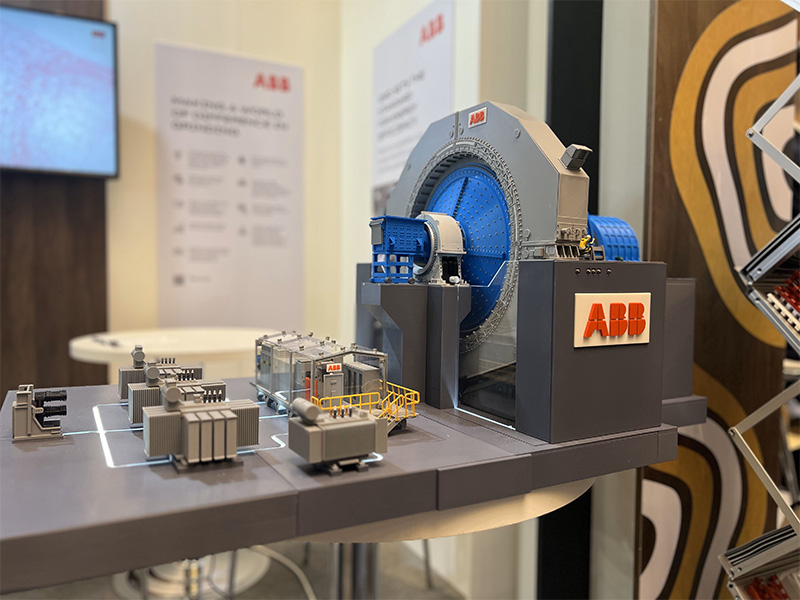

- ABB Kazakhstan’s stand captured significant attention with a striking 3D model of the Gearless Mill Drive (GMD), showcasing the company’s commitment to technical innovation and enhanced mining efficiency.

ABB Kazakhstan participated in the 15th anniversary of the International "Astana Mining & Metallurgy" Congress, reaffirming its role as a global technology leader in electrification and automation, enabling a more sustainable and resource-efficient future. The annual AMM Congress—one of Kazakhstan’s premier industry events—brought together key stakeholders for two days of high-impact engagement across exhibitions, meetings, and the prestigious Golden Hephaestus awards. The Congress serves as a vital platform for knowledge exchange, business collaboration, and policy discussion—underscoring its strategic value to Kazakhstan’s resource-driven economy.

The company was represented by Marcelo Perrucci (Global Head of Product Management, Marketing & Sales – Grinding, ABB Switzerland) ,Rustem Sharipov (Area Sales Manager, ABB Switzerland), Philipp Scholze (Sales Manager, ABB Germany) and Dossan Jumagaziyev (Local Business Line Manager for Mining & GMD, ABB Kazakhstan) as well as by other representatives from ABB Kazakhstan. Among the stand visitors were representatives from Kazakhmys, ERG, Kazzinc, Solidcore Resources, Qarmet, NFC, KAZ Minerals, and the Embassy of Sweden—strengthening our industry network within the event.

ABB Representatives on the First Day of AMM Congress 2025 near ABB stand

ABB Representatives on the Second Day of AMM Congress 2025 near ABB stand

From the first day, ABB’s exhibition stand became a focal point, driven by strong interest in its interactive 3D model of the Gearless Mill Drive (GMD). The GMD solution, which eliminates the need for a mechanical gearbox by directly coupling the motor rotor to the grinding mill, is a standout in ABB’s grinding solutions portfolio. This innovative design leads to higher system efficiency, reduced maintenance, and greater operational uptime—attributes that are critical in demanding mining environments where every second of operation counts.

3D GMD Model representation on ABB Stand

3D GMD Model representation on ABB Stand

A highlight of the first day was the visit by Rau Albert Pavlovich, Deputy Chairman of the Majilis (lower house of Kazakhstan’s Parliament), who received a comprehensive introduction to ABB’s footprint in Kazakhstan and its GMD technology.

Rau Albert Pavlovich, Deputy Chairman of the Majilis, visits ABB Stand on AMM Congress 2025

Mr. Sharipov explains more about GMD and Mining solution to Rau Albert Pavlovich

Mr. Sharipov explains more about GMD and Mining solution to Rau Albert Pavlovich

Day two of AMM 2025 continued ABB’s high engagement with a series of focused meetings that connected ABB experts with both current clients and potential partners. These discussions were centered on developing tailor-fit digital and automation solutions for Kazakhstan’s unique mining challenges. ABB’s reputation for adaptability and local partnership came to the forefront in these conversations—reinforcing the company’s commitment to empowering domestic industry capabilities.

Later that day, Mr. Rustem Sharipov joined a high-level strategic panel session titled “Domestic Value and Inter-Sectoral Cooperation”, held at AMM Congress. The session brought together industry and policy leaders to discuss Kazakhstan’s efforts to localize production, stimulate cross-sector cooperation, and create long-term domestic value in the mining and metallurgical sectors.

Rustem Sharipov presentation on the panel session

Group Photo of panel session participants

Mr. Sharipov‘s message echoed the broader ABB mission: delivering reliable, innovative technology that supports Kazakhstan’s resource sector in becoming more productive, competitive, and future-ready.

ABB Kazakhstan’s participation at AMM Congress 2025 underlines its long-term vision: enabling mining operations to move beyond routine performance to enduring productivity, efficiency, and sustainability. From showcasing advanced technology to shaping conversations around digital mining, ABB is building the foundation for a future where Kazakhstan’s mineral sector is not just running—but Engineered To Outrun.

ABB is a global technology leader in electrification and automation, enabling a more sustainable and resource-efficient future. By connecting its engineering and digitalization expertise, ABB helps industries run at high performance, while becoming more efficient, productive and sustainable so they outperform. At ABB, we call this ‘Engineered to Outrun’. The company has over 140 years of history and around 110,000 employees worldwide. ABB’s shares are listed on the SIX Swiss Exchange (ABBN) and Nasdaq Stockholm (ABB). www.abb.com

ABB’s Process Automation business automates, electrifies and digitalizes industrial operations that address a wide range of essential needs – from supplying energy, water and materials, to producing goods and transporting them to market. With its ~20,000 employees, leading technology and service expertise, ABB Process Automation helps process, hybrid and maritime industries outrun – leaner and cleaner. go.abb/processautomation