For over 90 years, Melbourne-based company Davey Water Products has been at the forefront of water management innovation, transforming the way it is conserved, treated, and filtered. From humble beginnings as a singular-person-operated business in Carlton, Victoria, Davey has grown into an iconic Australian brand known for its dependable and high-quality products. Whether it's ensuring perfect water pressure, providing healthy drinking water, protecting homes from fire and flood, delivering reliable water solutions to businesses or farms, or helping people maintain their clean and relaxing pools and spas - Davey’s solutions are trusted by customers worldwide.

ABB Motion Australia recently had the opportunity to sit down with key members of the Davey team: David Potts, Product Specialist – Commercial Business Unit; Matthew Dell’Olio, Category Manager- Water Transfer and Treatment; and Larry Wijesinghe, Production Manager- Commercial Business Unit. In this insightful discussion, they shared how Davey is developing a diverse range of solutions to meet the custom demands of their clients in sectors like irrigation, agriculture, farming, and high-rise commercial buildings. Their tailored systems are helping to address increasing market demands and a requirement to adapt to evolving application needs.

The Davey story

Davey is committed to supporting its Master Dealer network across several key market areas. These include small and large commercial irrigation (such as sports clubs, commercial gardens, and agriculture), commercial water supply, pressure boosting, wastewater management, and fire protection. In the realm of industrial processes, Davey's systems are integral to factory washdowns, quarries, and mining water pumping controls. Renowned for excellence, Davey consistently delivers high-quality, Australian-made solutions for these sectors and its applications.

The project: Controls Modernisation and the challenge to overcome

Davey recently underwent a Controls Modernisation Project aimed at developing advanced, reliable, and energy-efficient water pumping control systems. The company used to source products from over 100,000 different vendors and relied on several legacy pump controllers and drives to manufacture their systems. "It became unsustainable for us," said Larry. "Each component came from different manufacturers, each with its own mounting and assembly methods."

This inefficiency led to excessive Stock Keeping Units (SKUs), increased backend costs, and an ineffective system for Davey’s Master Dealer network. The challenge was to find a more streamlined and efficient solution that could be implemented across their entire business model thereby improving operations for every end customer overall.

Another significant challenge facing Davey was the need to have readily available variable speed drives (VSDs) to incorporate into their end-to-end solutions across both three-phase and single-phase power supplies). This availability of this offering would allow them to expedite the delivery of their offering to the market.

Why ABB Drives?

After a lengthy period of reviewing available technology providers, Davey chose ABB for their range of ACQ580 water-dedicated drives. These drives offered:

- Single-phase and three-phase power supply compatibility.

- A consistent yet versatile range.

- Improved backend processes, reducing SKUs and manufacturing times for their pump sets thanks to reduced components.

- Alignment with Davey’s premium brand positioning.

- Easy services-related support for both their company and customers.

- Seamless integration into the Davey pump control system, ensuring exceptional user-friendliness for their end customers.

- Reduced manufacturing and procurement costs for the drives used in their pump sets.

- Intelligent Pump Control functionality (IPC).

Davey has acquired ACQ580 drives with a range of different kilowatt ratings. These drives are used in various configurations, primarily for constant pressure water delivery with one or multiple pumps. Other applications include rainwater reuse and IoT-connected solutions.

"We’ve not only consolidated our offering but also entered into an important Original Equipment Manufacturing (OEM) partnership with ABB. This partnership has allowed us to successfully expand our range thanks to ABB’s drives," said Larry.

Davey’s 2MLV model pump set.

Davey’s 1MLV model pump set featuring an ABB drive on display for customers.

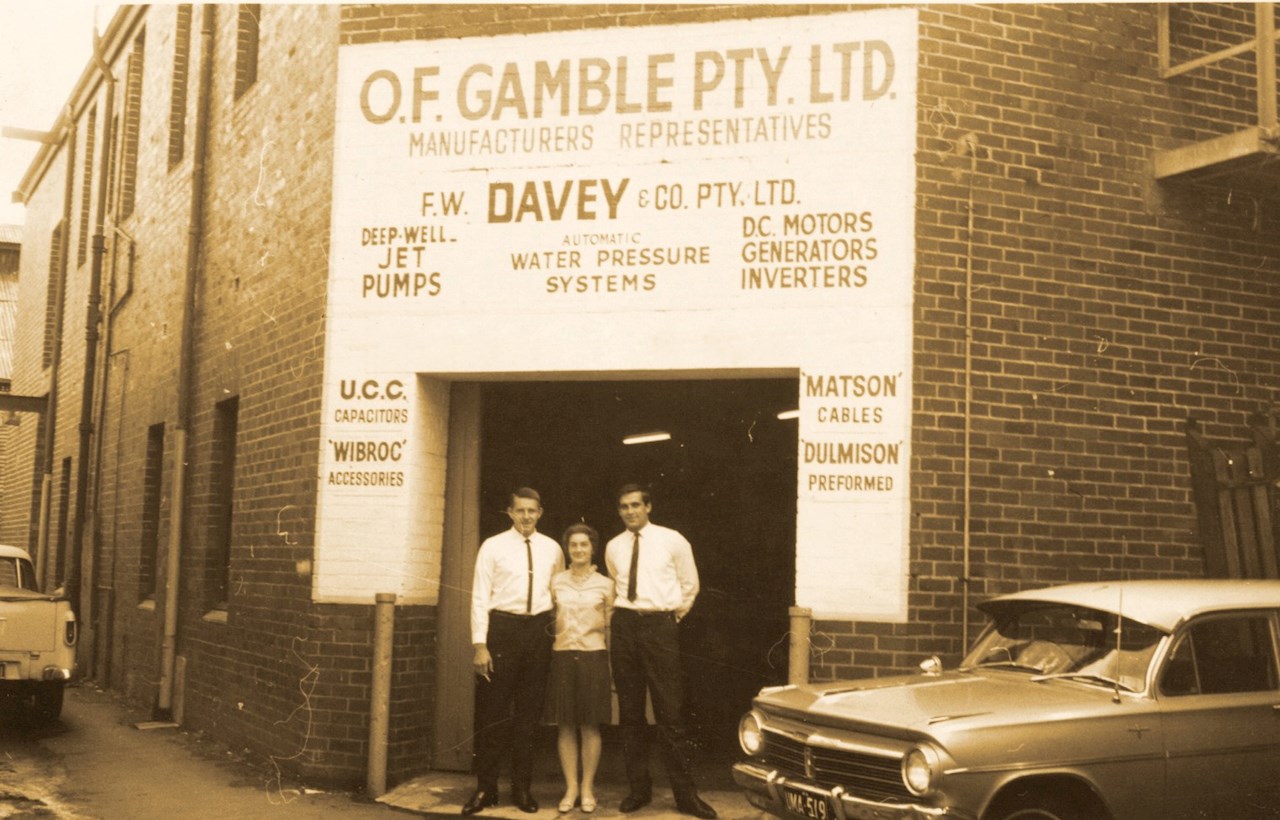

Humble beginnings: The Davey building circa 1940.

Davey’s headquarters in Scoresby, VIC. Australia.

Aerial view of the Davey factory floor.

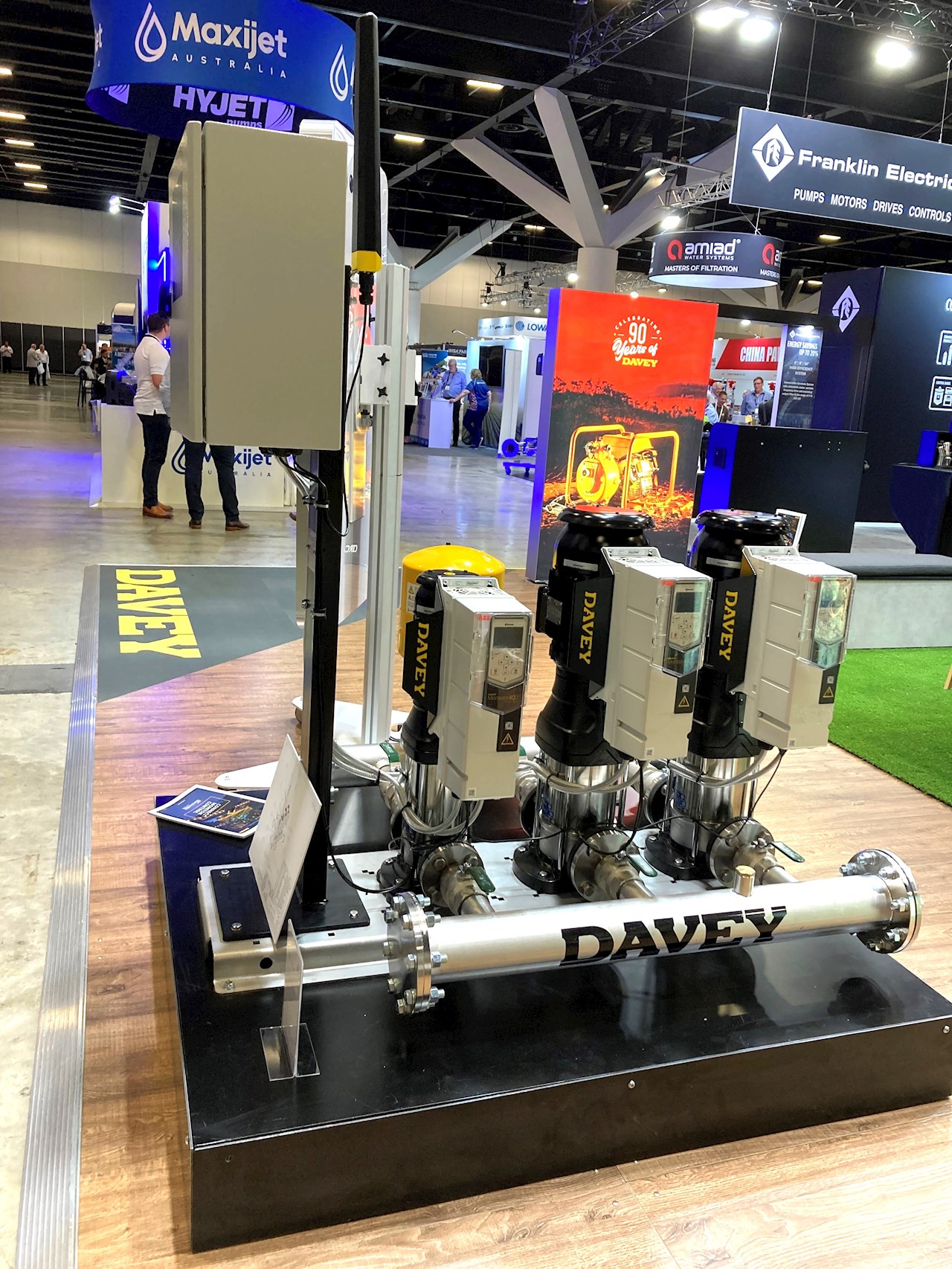

A Davey MonsoonIQ2 pump set featuring ABB drives on display at a national exhibition.

Several key benefits of an OEM partnership with ABB

ABB is dedicated to forming high-value partnerships with OEMs. This collaboration merges ABB’s engineering, manufacturing, and logistics strengths with the OEMs’ in-depth local market knowledge and expertise, enabling better service for customers around the world.

Davey's OEM partnership agreement with ABB has been a catalyst for advancements in their overall business model and operations. The union has provided benefits such as improved brand positioning, increased brand reach, enhanced technical support and training, and streamlined processes.

With the new ABB drive system, Davey can now incorporate up to eight drives per set. This enhancement better supports customer needs by adjusting water flow or pressure to meet specific application demands, such as varying requirements during different crop growth stages.

Matthew said, “This option gives farmers increased flexibility, using power only when needed, thereby reducing energy consumption. Equally important, we’ve expanded our geographic reach. With advanced technology, we can now better assist rural areas with limited infrastructure. This is a game-changer for local Australian farmers and agricultural businesses who depend on consistent operations for their livelihood.”

Larry adds, “We supply systems to farmers who must minimise downtime, as each hour of inoperability can cost them hundreds of thousands of dollars. Farmers have given us feedback that ABB drives are incredibly user-friendly. Thanks to the simple control panel, they can easily get assistance from a Davey services team member and troubleshoot over the phone. The programming is straightforward, making it easy to manage and change things like a set point or other drive configuration.”

The impact of ABB technology and local presence

David emphasised that “The ABB drives have ensured consistent quality in end-products, reliable operations, an enhanced and expanded product range, bolstered by the strong reputation of the ABB brand.”

In rural farming and agricultural communities, word of mouth is vital. Farm managers, responsible for daily operations like crop production, livestock management, and maintenance, can be very particular about everything from the HMI interface of a technology to its physical footprint. A single bad experience can result in losing their trust permanently. That's why it's a top priority for Davey to consistently provide their customers with a positive user experience.

When reflecting on his ABB-OEM partnership onboarding experience, David shared, “The support provided by the local ABB team in Australia throughout this process has been invaluable."

Larry concluded, “We received exceptional technical training on all essential ACQ580 drive programming features and functionality. The learnings have given our team a comprehensive understanding of the modern technology and confidence that we can fully help our customers whenever needed."

This modernisation project underscores Davey’s commitment to innovation, impactful industry partnerships, and continuous pursuit of customer satisfaction.