For manufacturers of printed circuit boards (PCBs), keeping pace with rapid developments in electronic device design means being able to adapt quickly to design changes without disrupting production. A major challenge lies in creating flexible and scalable production lines that can meet varied Qualified Product List (QPL) demands without redesigning entire systems each time.

Traditional PCB production often suffers from siloed automation cells with inconsistent interfaces, slowing retrofits, and reducing the potential for fast upgrades across facilities.

The challenge: Inflexible systems, high rework costs

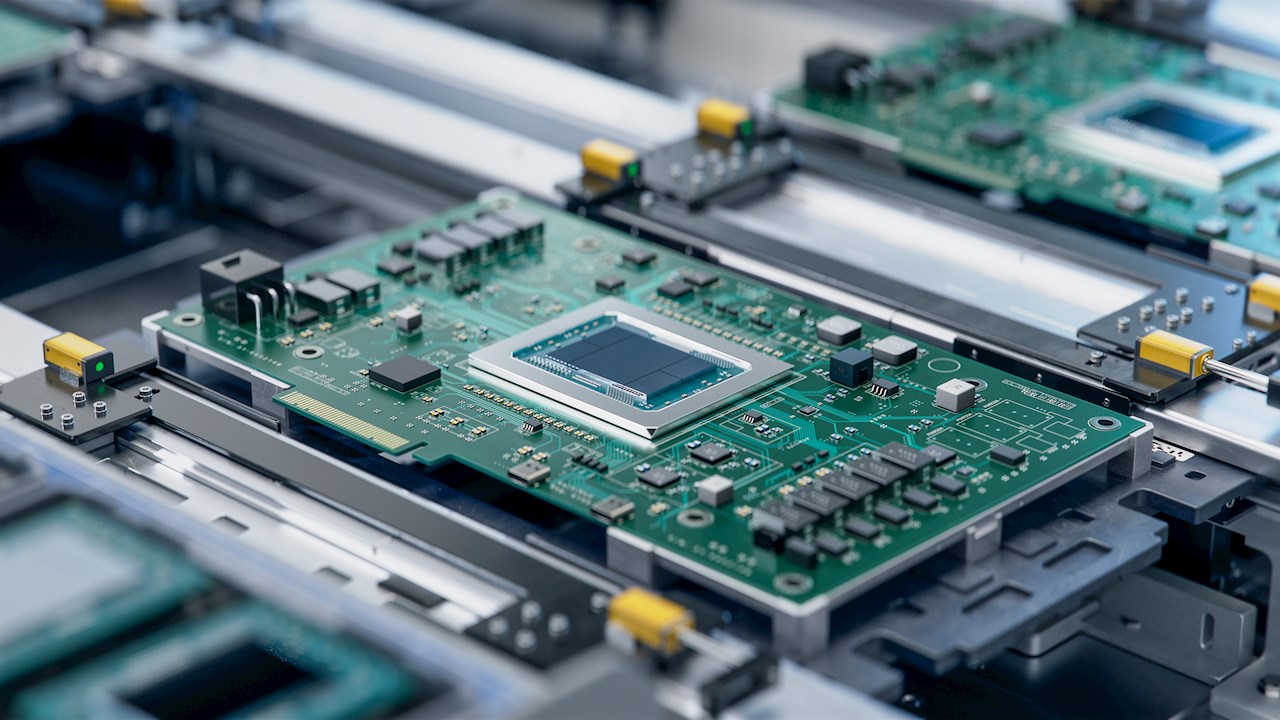

Ensuring efficient locking of PCBs is critical for ensuring a secure and stable connection to prevent components becoming loose or disconnected during operation. While many connectors are designed for automated assembly using robots, attention needs to be paid to the robot’s ability to correctly place and secure them to minimize the risk of production errors.

For one PCB manufacturer, scaling production for new product variants required a complete station-level redesign due to a lack of standardization. Every solution had to be customized, resulting in high engineering and integration costs, long changeover times, and limited scope for component and process reuse. The time taken to develop the solutions also caused excessive downtime and disruption to production.

The solution: A flexible, standardized robotic station

In this application, ABB’s IRB 1100 industrial robot was deployed as part of an automated solution to deliver high-precision material alignment and handling of flexible panels during the board-to-board connector locking process. The robot’s compact footprint and class-leading path accuracy were key factors in enabling the creation of modular, reusable cells that could be readily adapted to handle multiple PCB models.

Key features like the robot’s lean arm design, faster cycle times, and 8kg–9kg payload options made the IRB 1100 ideal for:

- Pre-flattening flexible panels

- Accurately positioning components for vision-guided pick-up

- Supporting high-throughput, 24/7 operations in compact cell layouts

The outcome: Faster scaling, simplified upgrades

By standardizing cell design and integrating the IRB 1100, the manufacturer achieved:

- Improved fungibility: Modules can be reused across applications with minimal redesign, simplifying retrofitting and upgrades and allowing process changes to be implemented easily at the module level without major disruptions

- Faster retrofits: Modular design enables process changes to be achieved quickly without full station rebuilds, saving time, cost and disruption

- Higher throughput: Up to 35 percent faster cycle times compared to similar robots thanks to the improved speed and accurate motion control delivered by ABB’s OmniCore™ controller

- Compact and lightweight: The IRB 1100 is 10% smaller footprint and over 20% weight reduction for easy installation

Why it matters

In PCB assembly, agility and precision go hand in hand. The combination of the modular automation system and the IRB 1100 helps to deliver both, enabling manufacturers to scale flexibly while staying competitive in a fast-changing electronics market.

Discover more about IRB 1100

Contact us for more information