- Project company Arctial has formed an industrial and investment partnership to conduct a feasibility study for low-carbon aluminium production in Finland

- The Arctial aluminium smelter would become the first new primary aluminium smelter constructed in continental Europe in over 30 years, strengthening the region’s supply chain

- ABB will be responsible for assessing the feasibility of an electrification and automation scope

ABB has joined project management organization Arctial as an investor and will become a member of a partnership of companies set to carry out in-depth feasibility studies for the Greentop low-carbon aluminium smelter project in Finland. This development is poised to be critical to Europe’s materials supply chain. Investment details were not disclosed. The deal was signed in the first quarter of 2025.

Arctial has committed to explore the business case for a manufacturing facility in the Kokkola and Kronoby regions on the west coast of Finland, evaluating commercial, environmental, social and technical factors. It would represent the first primary aluminium development in continental Europe for over 30 years, bolstering supplies at a time of high global demand from industries including automotive, electronics, packaging, aerospace and construction. The project team anticipates the use of low-carbon energy from existing and new renewables infrastructure and relies on local and global industry partners.

As a global technology leader, ABB will be responsible for assessing the feasibility of an electrification and automation scope, including the use of high power rectifiers, high voltage switchgear, transformers and substations. A team will work within the partnership to develop front end engineering and design (FEED), an early works package description, budget and timeline, and safety risk assessment. The objective will be to achieve an operation that is energy and resource efficient, reliable and safe.

ABB brings electrification and automation expertise to large-scale projects. Image ABB

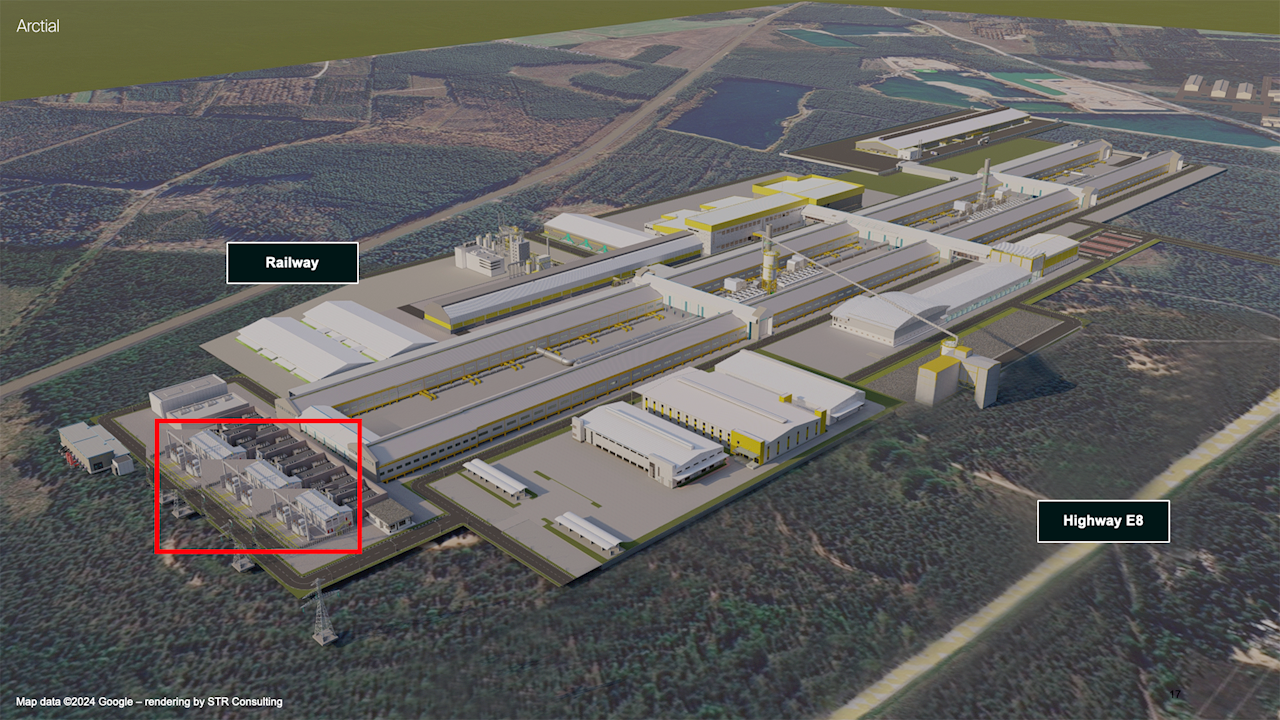

A partnership team of companies are working together to understand the industrial and investment factors of the project. Image Arctial

Project company Arctial is exploring the business case for an aluminium facility in Finland. Image Arctial

“Working in partnership across industrial supply chains is a critical part of our strategy,” said Torbjörn Sternsjö, CEO of Arctial. “Our commitments through collaboration bring invaluable strategic insights, increased knowledge and additional networks. We’re looking forward to the results of what we will achieve together with our investment partners.”

“As a partner with early involvement in Arctial’s low-carbon aluminium project we intend to bring not only investment but also our generations of expertise,” said Joachim Braun, Division President, ABB Process Industries. “We have gained insight into the impacts this project can have across the European supply chain for industries and everyday consumers. We believe that our technological influence can help this development become reality.”

Arctial anticipates making a final investment decision (FID) regarding a production facility during 2026−2027. This decision will follow a comprehensive evaluation process, with the feasibility study serving as a crucial initial step.

ABB is a global technology leader in electrification and automation, enabling a more sustainable and resource-efficient future. By connecting its engineering and digitalization expertise, ABB helps industries run at high performance, while becoming more efficient, productive and sustainable so they outperform. At ABB, we call this ‘Engineered to Outrun’. The company has over 140 years of history and around 110,000 employees worldwide. ABB’s shares are listed on the SIX Swiss Exchange (ABBN) and Nasdaq Stockholm (ABB). www.abb.com

ABB’s Process Automation business automates, electrifies and digitalizes industrial operations that address a wide range of essential needs – from supplying energy, water and materials, to producing goods and transporting them to market. With its ~20,000 employees, leading technology and service expertise, ABB Process Automation helps process, hybrid and maritime industries outrun – leaner and cleaner. go.abb/processautomation