As data centers evolve to meet the demands of AI, cloud computing, and high-density workloads, cooling systems are under more pressure than ever. High performance Central Processing Units (CPUs) and Graphic Processing Units (GPUs) produce even more heat without proper cooling; internal temperatures can quickly exceed safe operating thresholds.

Many systems are transitioning from traditional air cooling to advanced liquid cooling solutions, but the chiller is a common element in both systems. Chillers are often placed outdoors, exposed to extreme temperatures and electrical noise, and here comes a hidden challenge: contactor failures in 60Hz HVAC chiller applications.

So, what’s really going wrong—and how can we fix it?

Traditional Contactors

An HVAC customer once told me: “Since we switched to your AF contactors, we’ve had no more early failures—not in contactors, not in compressors.”

That feedback highlights a critical but often overlooked issue: Why do some contactors perform reliably while others fail in identical applications? The answer: The coil—and how it’s controlled.

Why 60Hz HVAC chiller applications are so demanding

When voltage is applied to a contactor coil, it creates a magnetic field that pulls a movable armature toward a fixed core. This action closes the power contacts, allowing current to flow to the load. The contacts remain closed as long as the coil remains energized.

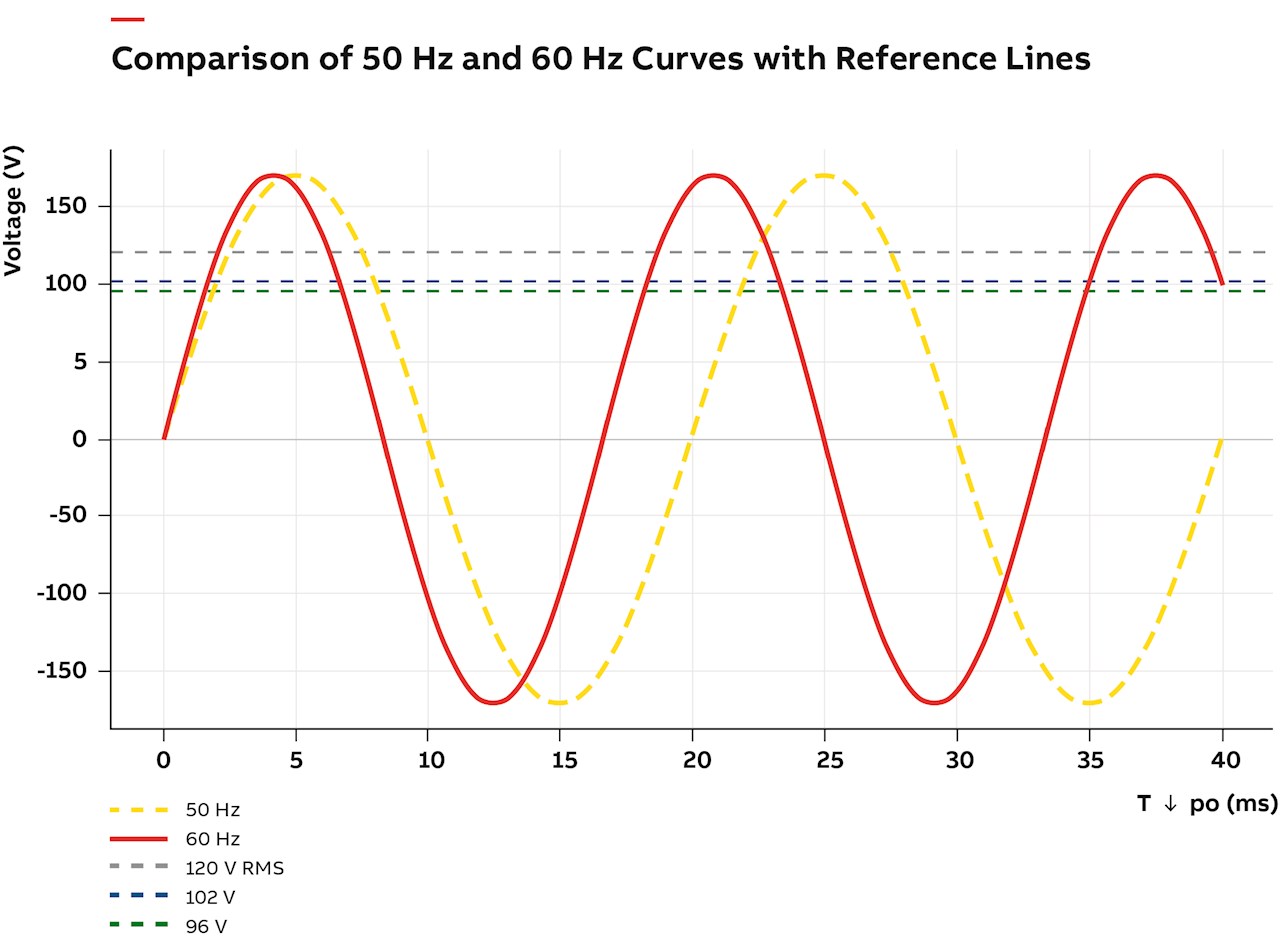

Most traditional contactors use electromagnetic coil technology designed to operate at both 50Hz and 60Hz. While this dual-frequency design simplifies inventory and logistics, it introduces a critical compromise: contactors behave differently at 50Hz than they do at 60Hz. These differences can lead to performance instability—especially in demanding HVAC applications where voltage fluctuations and high ambient temperatures are common.

In dual frequency coils, the pick-up voltage is higher at 60Hz than at 50Hz. These operating limits vary depending on the number of auxiliaries installed and the operating temperature. In HVAC chillers, contactors are used to start compressors, fans, and pumps—often outdoors, exposed to extreme temperatures and electrical noise. A typical mode of failure in these applications is that the contactor fails to close, leading to overcurrent, stress, and motor failure.

AF Benefits - Continuous Operation

Traditional electromagnetic coils, designed for both 50Hz and 60Hz, are a compromise. They’re more vulnerable to:

- Voltage fluctuations

- High ambient temperatures

- Side-by-side mounting heat buildup

- Interference from variable speed drives

These conditions can cause chattering, arcing, and ultimately compressor failure—a costly outcome for any data center.

AF Contactor Technology

In 2006, ABB introduced a breakthrough: the AF contactor. Unlike traditional coils, AF contactors use an electronically controlled coil that adapts to voltage variations and ensures stable operation—even in harsh environments.

Key innovations include:

- 3D magnetic design for precise control, reliable performance and efficient operation

- Up to 80% lower coil energy consumption

- Wide control voltage range (100–250V AC/DC, 50/60Hz)

- Built-in surge suppression

This isn’t just a premium option—it’s ABB’s standard. And it’s trusted in millions of installations worldwide.

Performance Comparison

Choose Smart. Choose Stable. Choose AF.

In high-stakes environments like data centers, even small components can have a big impact. The contactor may be just one part of your HVAC system—but it’s the part that keeps everything running.

If you’re designing or maintaining 60Hz HVAC systems, don’t settle for outdated coil technology. Choose a solution engineered for reliability, efficiency, and peace of mind.

About the Author

With a strong track record in global product management, marketing, and business development, Albert Martinez bridges technical expertise with commercial strategy across the industrial automation and control sectors. He holds a Master’s in Industrial Engineering from ETSEIT and has grown into key leadership roles, known for effectively managing cross-functional teams and driving sustainable market growth. Passionate about industrial innovation, Albert is committed to helping OEMs confidently upgrade their systems using ABB’s advanced control solutions. His blend of technical insight and strategic vision positions him as a key leader in the electrification business.