- Two custom-engineered Gearless Mill Drive (GMD) systems are en route to the new copper concentrator project at Centinela

- The technology systems deployed by ABB will also provide real-time data to support better decision-making and minimize downtime

Antofagasta Minerals (AMSA) Centinela mine will soon deploy ABB Gearless Mill Drive (GMD) systems for its new copper concentrator project under construction in Chile. The advanced technologies are expected to enhance operational efficiency, deliver real-time insights, support informed decision-making and reduce unplanned downtime at the site.

The GMD systems, custom-designed by ABB, recently completed Factory Acceptance Tests (FAT) for the stators that will power the ball mill motors – responsible for the final stage of ore size reduction in the process.

Manufactured in Bilbao, Spain, the stators were shipped to Puerto Angamos (Mejillones) and then transported to the Centinela Mining District. There, they will play a key role in the GMD’s electrical drive system by generating the magnetic field needed to rotate the ball mills.

These systems were selected with consideration for the harsh outdoor desert conditions. Each includes 27-foot diameter ring motors with 19.6 MW of power (paired with a control block) and three cycloconverter transformers, all designed to maximize performance.

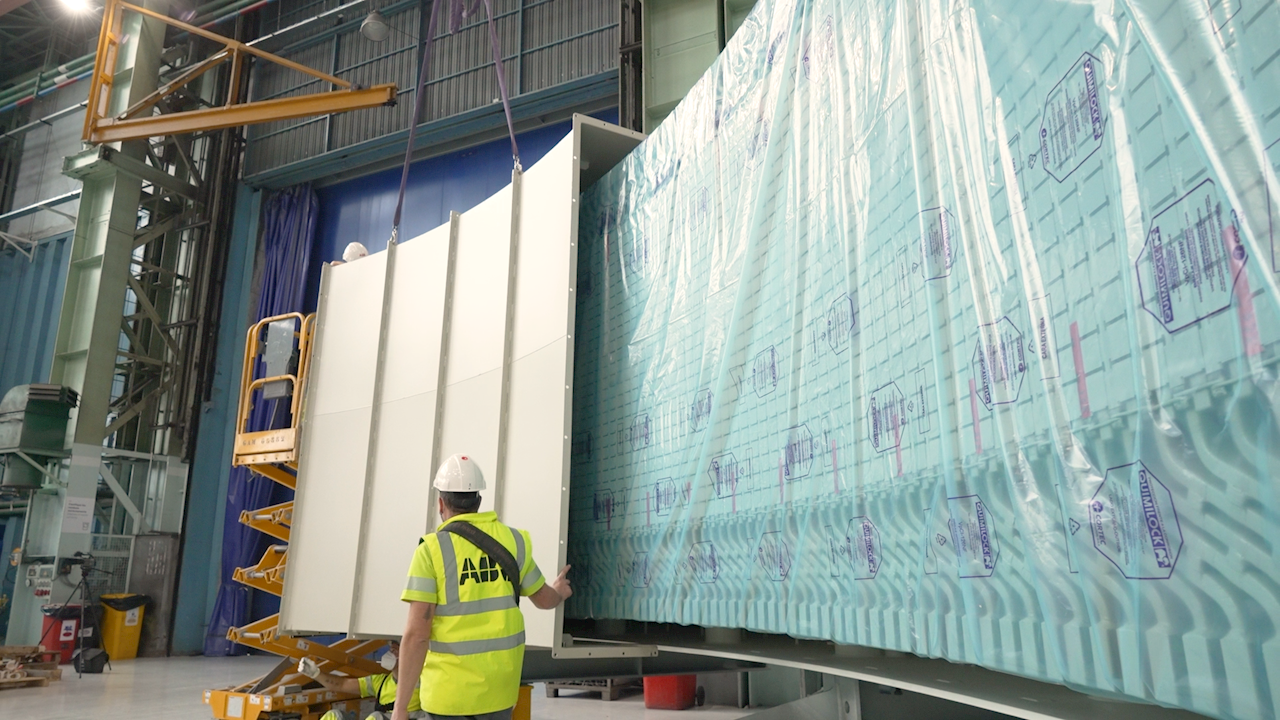

A section of ABB Gearless Mill Drive (GMD) being loaded ready for transit to Chile. Image ABB

The ABB Ring Motors factory in Bilbao has long held the expertise and technologies for constructing GMDs. Image ABB

Once installed and commissioned on site the GMD will support efficient performance, including through variable speed capabilities. Image ABB

Each GMD must be carefully wrapped and housed in customized casing for shipment. Image ABB

One of the most important features of this technology in terms of efficiency and performance is its variable speed capability, which allows plant operators to respond more quickly to changes in ore composition. Process optimization functions will further enhance grinding availability and efficiency while reducing energy consumption and emissions.

“Antofagasta Minerals’ decision to adopt our Gearless Mill Drive technology marks a significant milestone for ABB in the South American mining sector,” said Wilson Monteiro, Global Business Line Manager for GMD, ABB Process Industries.

With global copper demand expected to rise in the coming decades, the expansion of Centinela – known as Nueva Centinela – is a strategic priority for AMSA. The new concentrator will increase copper production by 144,000 tons per year and extend the mine’s life by at least 30 years.

AMSA chose ABB’s Swiss-engineered GMD systems to boost plant productivity and leverage existing infrastructure.

Since every hour of downtime can cost mining companies hundreds of thousands of dollars, minimizing these events is critical. According to the manufacturer, the new systems provide a broader set of real-time data to help prevent unplanned failures. Combined with ABB’s remote monitoring capabilities, operators will be better equipped to anticipate maintenance needs and make more informed decisions.

ABB is a global technology leader in electrification and automation, enabling a more sustainable and resource-efficient future. By connecting its engineering and digitalization expertise, ABB helps industries run at high performance, while becoming more efficient, productive and sustainable so they outperform. At ABB, we call this ‘Engineered to Outrun’. The company has over 140 years of history and around 110,000 employees worldwide. ABB’s shares are listed on the SIX Swiss Exchange (ABBN) and Nasdaq Stockholm (ABB). www.abb.com

ABB’s Process Automation business automates, electrifies and digitalizes industrial operations that address a wide range of essential needs – from supplying energy, water and materials, to producing goods and transporting them to market. With its ~20,000 employees, leading technology and service expertise, ABB Process Automation helps process, hybrid and maritime industries outrun – leaner and cleaner. go.abb/processautomation