A rapidly changing data centre industry

According to the International Energy Agency (IEA), the number of internet users worldwide has more than doubled since 2010. Their report published in April 2025 stated that global investment in data centres amounted to half a trillion dollars in 2024. This was driven by society’s increased dependency on smart technologies, cloud-based communication and file sharing, content streaming, government initiatives and regulations, and digital services for everyday occurrences like ordering goods and services. Enter the era of Artificial Intelligence (AI), and the IEA projects that energy demands from AI data centres will quadruple by 2030.

This surge is fueling growing concerns about soaring electricity demand as the sector’s electricity consumption has increased by around 12% per year since 2017 – that’s four times faster than the rate of total electricity consumption.

The Australian Energy Market Operator (AEMO) has forecasted that data centres in Australia could account for nearly 15% of Large Industrial Load (LIL) consumption by 2033-34. The country’s climate, with its extremes in temperature, further increases the cooling demands of data centres and their cooling infrastructure. Electricity consumption per square metre in a data centre can be 10 to 50 times higher than in a typical office building, making HVAC efficiency critical.

How can data centre operators improve energy efficiency and guarantee reliability?

The IEA considers energy efficiency to be the “first fuel,” representing the energy that does not have to be used in the first place.

Meeting today’s demands, regulations, and market and consumer expectations, while reducing energy consumption now and into the future – has become essential for data centre operators.

The trajectory presents both significant opportunities and critical infrastructure challenges that demand strategic technological solutions.

Enter variable speed drives (VSDs). The intelligently automated technology adjusts cooling systems based on server load and environmental conditions. A data centre facility is therefore able to easily maintain optimal operating conditions and the risk of equipment failure is drastically reduced.

Josh Paikada, Drive Products Segment Manager for HVAC and Infrastructure at ABB Australia said, “The relationships between pump or fan shaft speed, flow rate, pressure, and power are governed by the affinity laws, which show that reducing the speed of a fan or pump by 20% can save as much as 50% of energy.

Data centres most often operate at partial loads, typically reaching peak demand in the afternoon and evening, when most people draw on services such as web conferencing and streaming. As a result, operators can easily achieve energy savings of 25% or more by simply reducing cooling application speeds at non-peak hours.”

Another important consideration is that drives don't just affect cooling system efficiency. They can also impact the overall efficiency of the electrical distribution network of a data centre. This is because, depending on the drive design, they can generate electromagnetic noise, called harmonics, in the network.

The power problem you can’t see

Harmonics are electrical disturbances induced by non-linear loads such as 6-pulse drives. If a facility is designed incorrectly or expands beyond the original design, harmonics will distort the power waveform and reduce efficiency, causing overheating, overloading of transformers, generator failure, and damage to equipment.

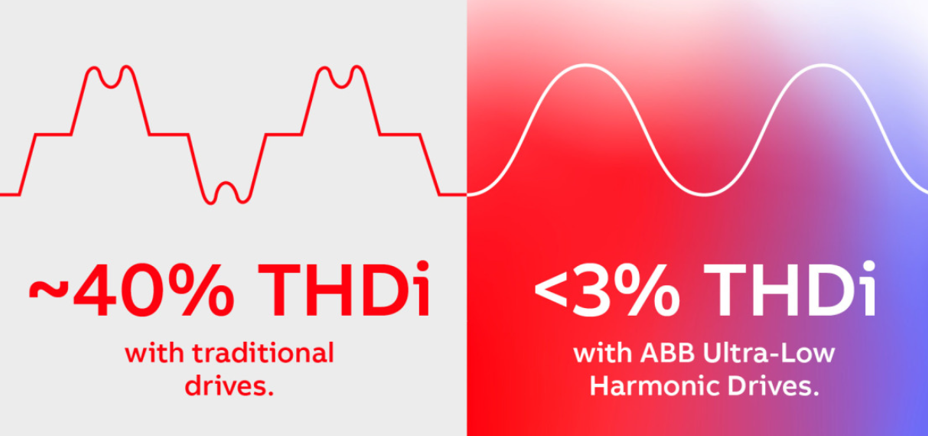

ABB Australia works closely with their Authorized Value Provider, IPD to support the design and supply of motors and drives for data centres. Michael Linden, National Business Development Manager at IPD said, “Harmonics result in increased line currents, and this will lead to electrical losses in cables and other power network equipment as power is lost to heat. These can be significant. For example, a standard drive might lead to about 40% total harmonic distortion (THDi), creating a higher RMS current and resulting in about 20% higher energy losses in cables.”

Michael emphasised that it’s possible to avoid this by using ABB’s ultra-low harmonic (ULH) drives as a scalable, decentralised, harmonic mitigation solution. These drives cut THDi to less than 3%, meaning they generate almost no harmonics to begin with, and significantly reduce electrical and thermal losses, constituting a more optimised operating system.

“Furthermore, these drives are fully compliant with the strictest US, European, and Australian regulatory standards,” he said.

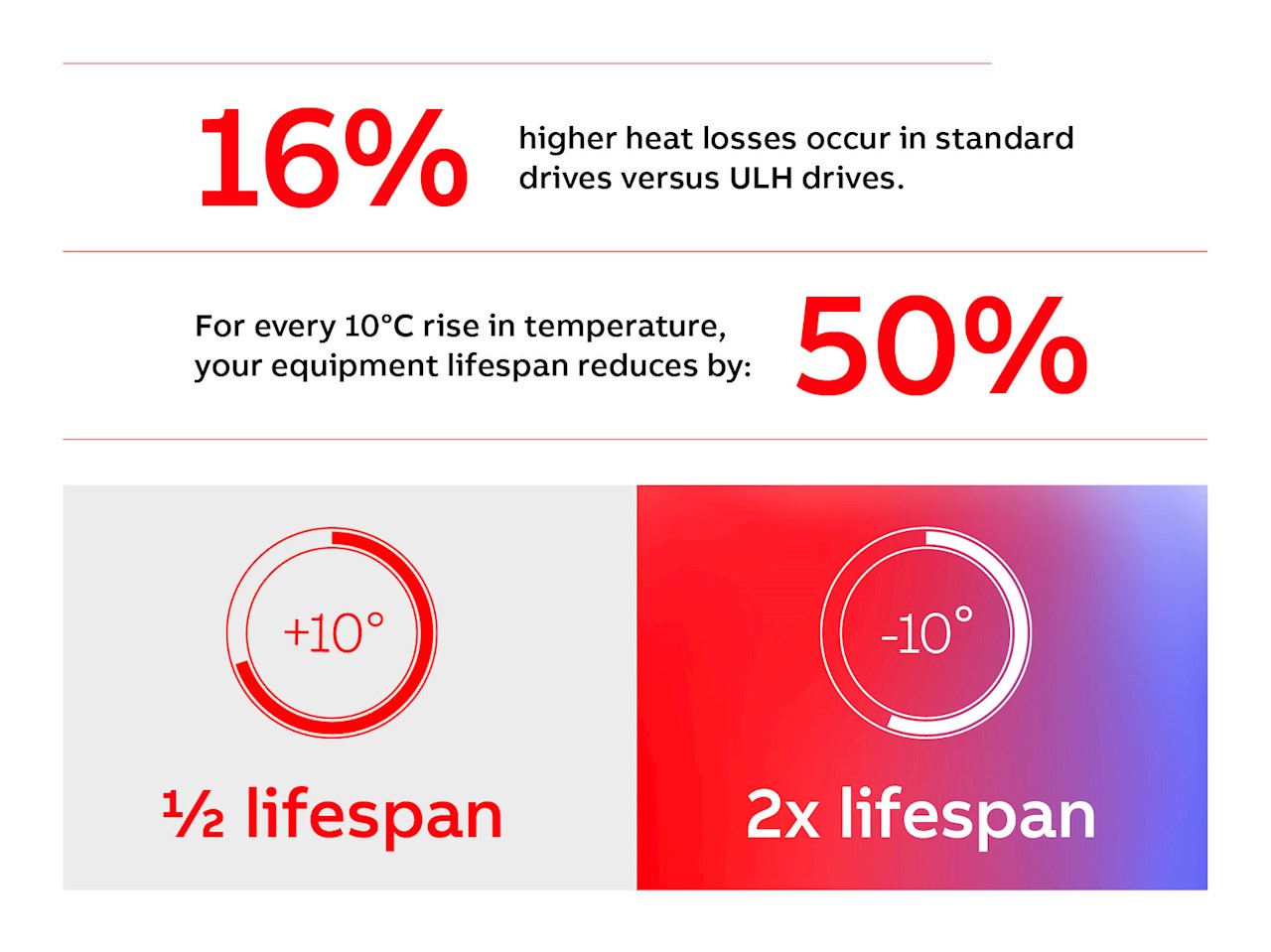

ABB’s ultra-low harmonic drives offer power quality, consistency, reliability, and energy savings. This suit of solutions can double the equipment lifespan in data centres.

ABB’s ultra-low harmonic (ULH) drives cut THDi to less than 3%, meaning they generate almost no harmonics to begin with, and significantly reduce electrical and thermal losses, constituting a more optimised operating system.

ULH drives contribute to data centre sustainability

ULH drives have an important additional benefit as sustainability extends beyond efficient use of energy. Less material usage over a data centre's lifetime can also make it more sustainable and reduce its carbon footprint.

As previously mentioned, a typical drive may result in higher line current due to the 40% harmonic distortion. It is standard practice to oversize power network equipment such as transformers, generators, switchgear and cabling to handle this current.

For example, transformers might need to be oversized by about 35% when using standard drives, but with ULH drives, this margin can be reduced to 10%. Similar principles apply to generators, cables, and other power network equipment, with the ULH drive reducing the need to substantially oversize the system.

When addressing generators, using a ULH drive can reduce the need to oversize by up to 50%, while cable sizing requirements can be lowered by ~12%. Smaller equipment requires fewer raw materials and consumes less energy during the manufacture of equipment. This leads to a smaller carbon footprint for the data centre. Because of this, business owners will notice reduced project costs.

Sustainability also manifests in longer equipment lifespans. Drives help with this as they eliminate mechanical and electrical stress on systems. As an example, by starting and stopping cooling applications in a smooth way, high inrush currents and the potential for water hammer is reduced. Drives also help operators avoid resonant frequencies and devastating vibrations, which can damage cooling system equipment.

In addition, advanced drive technology can deliver valuable insights, alerting operators to potential operational issues such as a bearing failure - by identifying when a drive is drawing a higher current than usual for the same load. This proactive monitoring leads to a longer lifetime for system equipment, eliminates unplanned outages, and supports more sustainable operations by promoting wiser usage of existing materials, and encouraging a repair rather than a replace approach.

Bearing currents can prompt motor damage and are often a result of common-mode voltages and currents within the power drive system. Unlike standard 6-pulse drives, ABB’s ULH drives for HVACR applications come with a built-in Common Mode Filter as a standard feature to prevent these bearing currents.

Proof of concept: Real scenarios from data centre projects delivered by ABB

A large data centre operator based in Asia consulted with ABB when planning a new facility build. The operator recognised the potential negative impact of harmonics when it came to operational efficiency as well as the sizing and performance of the overall electrical infrastructure.

By specifying ULH drives for their cooling system from the outset, they were able to avoid any issues that are typically caused by harmonics. The operator specified a requirement to limit total harmonic distortion to below 5%. Further requirements included the availability of a local service center for 24/7 technical support and the ability to deliver the drives to meet the project timeline.

Consequently, this data centre operator has installed almost 100 of ABB's ACH580 ULH drives into their facility. This drive has been designed and engineered specifically to support pump, fan, and compressor applications within air-handling units, chillers, and cooling towers in HVAC systems. The drives feature built-in software which enables more efficient process control in HVAC systems.

In Australia, Climatech Group has deployed ABB’s ACH580 drives across numerous data centre projects including high-profile installations.

"For over a decade, we’ve relied on ABB’s ACH580 series...In fact, I haven’t purchased any other drives in over 12 years."

Che Cavill, Head of Data Centre Operations – Construction, at Climatech Group says these HVAC‑specific drives deliver reliable performance, fast delivery, and seamless integration (up to large power sizes), making them an ideal off-the-shelf solution for mission‑critical environments.

“For over a decade, we’ve relied on ABB’s ACH580 series—and its predecessors—as our go to HVAC drives. They combine all the essential HVAC-specific functions and settings we need with off the shelf availability up to substantial power ratings, ensuring fast, hassle free deployment. I confidently recommend ACH580 drives. In fact, I haven’t purchased any other drives in over 12 years.

When it comes to built-in harmonic mitigation, the ACH580-31 ULH drive typically exceeds requirements, delivering ultra low THDi and often eliminating the need for external filters. I recommend this drive for applications where power quality is critical,” said Che.

When considering the importance of partnering with a trusted and reliable supplier for data centre infrastructure Che continued, “We’ve consistently experienced outstanding customer service from Michael Linden and the wider IPD team—particularly when timing was critical. IPD’s dedication, industry knowledge, and customer-first approach are key reasons we partner with them on every data centre projects.”

Australian data centres are under rising pressure. Heavier workloads, tighter sustainability targets, and wasted energy in the form of harmonic distortion are having a major impact on operations. Staying competitive demands infrastructure that can adapt, grow, and perform without compromise.

ABB’s Ultra-Low Harmonic (ULH) drives meet that challenge head-on as a scalable solution that cancels harmonics at the source, boosts efficiency, and unlocks more budget flexibility while supporting the achievement of ambitious green goals.

Get started: Drive your data centre differently

- Step 1. Conduct a thorough assessment of your data centre’s cooling infrastructure design to evaluate performance factors such as heat generation, energy efficiency, and harmonic distortion.

- Step 2. Engage with an ABB drives expert to identify opportunities for performance improvement, design enhancements, and energy optimisation.

- Step 3. Partner with a global technology leader like ABB - delivering innovative, digital, and monitoring solutions that enhance reliability, scalability, sustainability, and energy efficiency - ensuring your data centre is optimised for today and future-ready for tomorrow.

WE GRATEFULLY ACKNOWLEDGE THE CONTRIBUTIONS OF MARIA LUSHINA, GLOBAL PRODUCT MARKETING MANAGER FOR ABB DRIVES, WHOSE INSIGHTS HELPED SHAPE THIS ARTICLE.

References:

- “Energy and AI”, report published by the International Energy Agency, April 2025.

- “2024 Electricity Statement of Opportunities,” webinar presented by Australian Energy Market Operator (AEMO), September 2024.