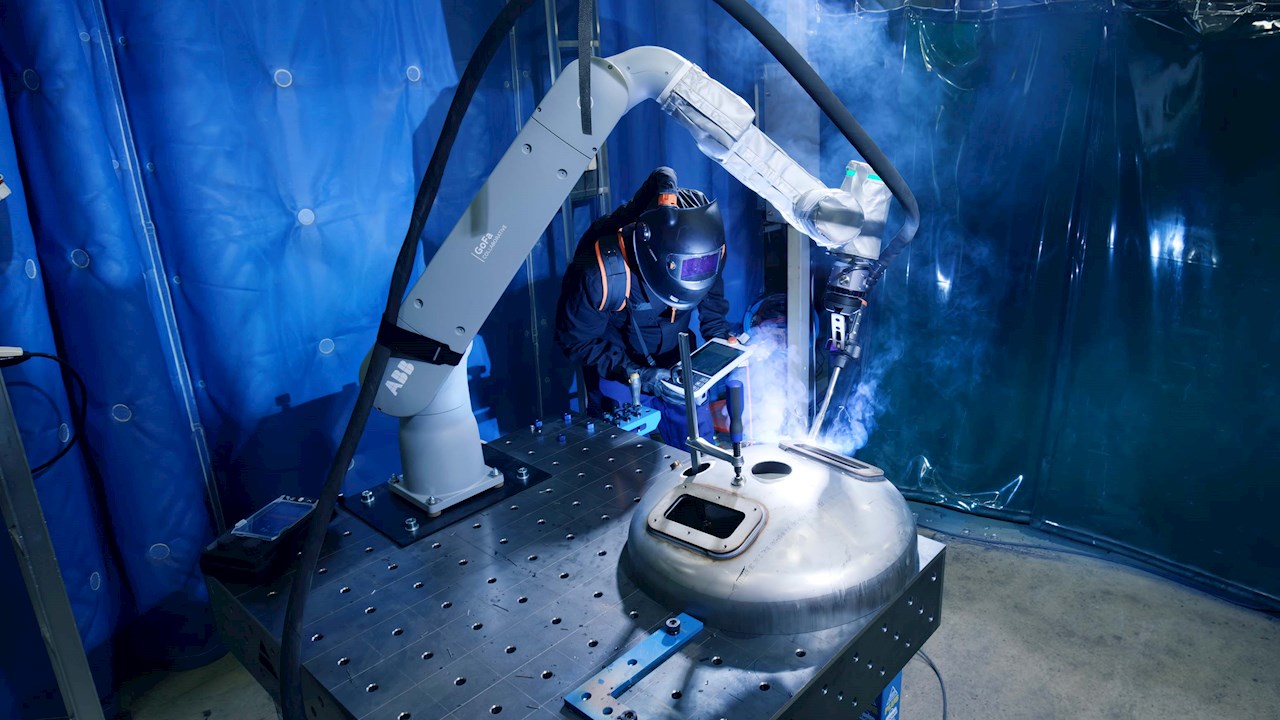

- The Application: The GoFa cobot is enabling 360-degree, continuous welds on irregular and varied part stainless steel objects, significantly reducing post-processing and improving production efficiency.

- The Challenge: Metos Oy, global leader of professional stainless steel kitchen equipment, needed a welding solution that could deliver flawless, pressure-rated welds for small batches of high-spec products, which feature tubular structures and circular shafts that required continuous, precision welding.

- The collaborative welding solution: By Integrating ABB’s GoFa™ CRB 15000 collaborative robot, known for its best-in-class precision and repeatability, along with Kemppi’s Master M 358 welder and GXe-C torch, METOS was able to achieve high quality, consistent welds which has improved welding productivity by thirty percent.

Known for their premium bratt pans and other high quality steel products used in commercial kitchens, hospitals and schools, Metos faced challenges in maintaining flawless, pressure-bearing welds on circular and tubular components, many of which are visible parts in kitchen manufacturing and must meet strict aesthetic and safety requirements.

Manual welding of such parts often results in interruptions due to position changes. Therefore, automating the process can eliminate the inconsistencies in quality by performing continuous welds in a single, smooth motion, ultimately enhancing quality and visual appearance.

“GoFa has dramatically improved our cycle times and reduced post processing by sixty percent, while maintaining premium quality.” Risto Koskelainen, Production Manager at Metos

At the heart of the application’s success is GoFa’s ease of programming and advanced capabilities such as seam tracking, wire search, and adaptive welding, which allow the application cell to compensate for part variation without requiring complex fixtures. The cobot’s ability to handle tricky work pieces helped the company automate even the most challenging all-round welds without compromising the quality.

“GoFa’s intuitive programming allows us to adapt quickly, even when we’re producing small series with varying geometries’’, explains Risto Koskelainen

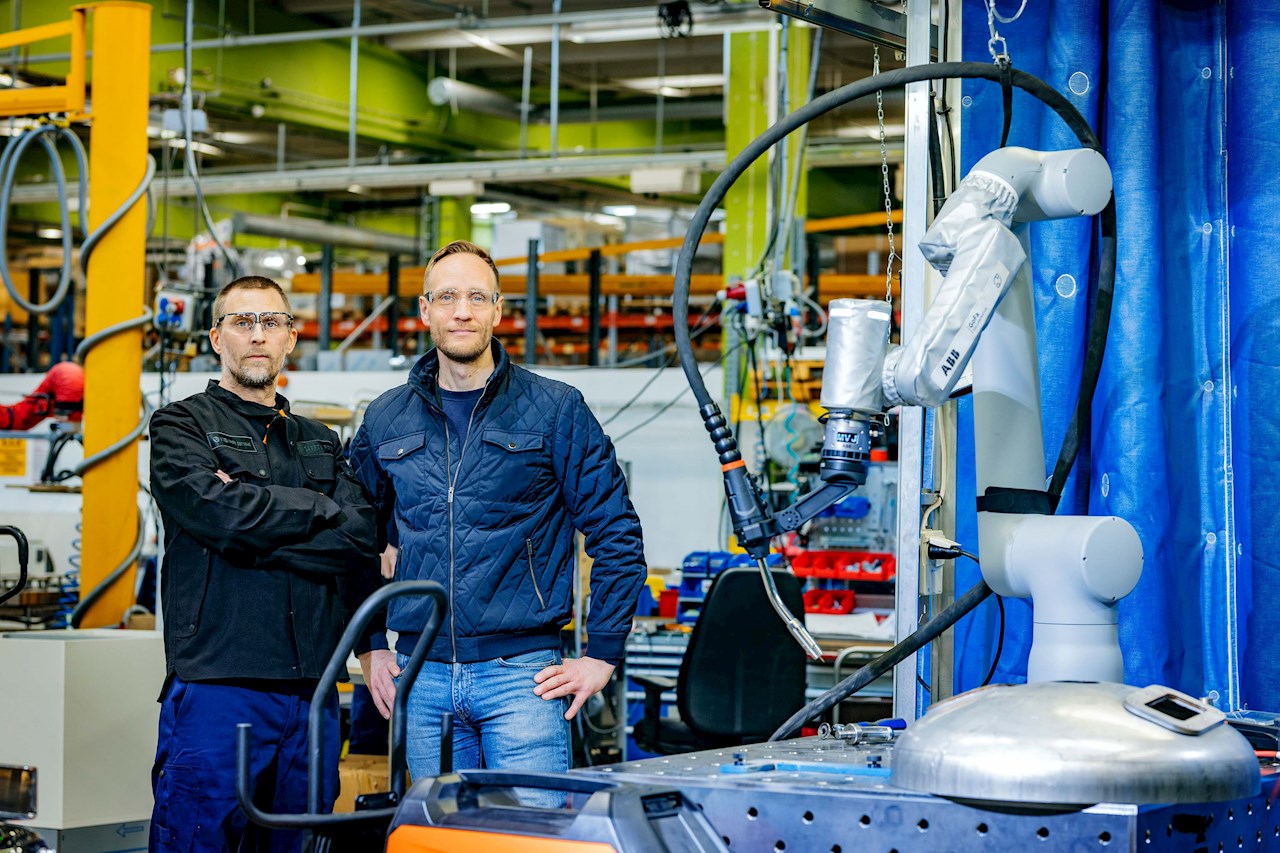

The success of this deployment is the result of a close collaboration between ABB, Kemppi, and the Metos team. After a one-week pilot, ABB provided training and hands-on support to onboard welders like Jani Paahtama, who quickly adapted to programming and operating the GoFa. “I’ve been surprised by how fast and easy it is to program GoFa even for complex weld paths.” Paahtama explains.

ABB’s local sales and support team has remained involved throughout the project, ensuring the solution continues to evolve with Metos’ needs. ‘GoFa brings the agility of collaborative automation to a highly skilled process like welding,” says Juha Mainio, ABB Area Sales Manager. “This is exactly the kind of outcome we aim for, supporting customers like Metos in achieving world-class results with smart, accessible automation.

With leading manufacturers like Metos reporting a significant boost in productivity, ABB’s GoFa™ cobot is proving its precision, ease of use, and flexibility in high demand welding applications, paving the way for wider adoption of collaborative welding across diverse industries.

Learn how to achieve faster, safer, and more consistent welding with ABB cobots, discover our welding guideline.

ABB is a global technology leader in electrification and automation, enabling a more sustainable and resource-efficient future. By connecting its engineering and digitalization expertise, ABB helps industries run at high performance, while becoming more efficient, productive and sustainable so they outperform. At ABB, we call this ‘Engineered to Outrun’. The company has over 140 years of history and around 110,000 employees worldwide. ABB’s shares are listed on the SIX Swiss Exchange (ABBN) and Nasdaq Stockholm (ABB). www.abb.com

ABB Robotics & Discrete Automation as one of the world’s leading robotics and machine automation suppliers, is the only company with a comprehensive and integrated portfolio covering robots, Autonomous Mobile Robots and machine automation solutions, designed and orchestrated by our value-creating software. We help companies of all sizes and sectors - from automotive to electronics and logistics – to outperform by becoming more resilient, flexible and efficient. ABB Robotics & Discrete Automation supports customers in the transition towards the connected and collaborative factory of the future, operating leaner and cleaner for a better future. The business area employs approximately 11,000 people at over 100 locations in approximately 53 countries. go.abb/robotics