JH Tester Industrial Automation (JH Tester) is a fully turnkey solution provider of industrial automation systems that incorporate advanced robotics technology.

Based in Prestons, New South Wales, the company has been successfully designing and engineering systems for manufacturing and industrial applications since 1980. In addition to catering to the unique requirements of local businesses looking to improve their operations in sectors such as food and beverage, pharmaceuticals, mining, and material handling, their systems have been exported to over 30 countries worldwide.

CEO Murray Tester emphasises that JH Tester’s legacy remains rooted in developing smart, innovative, solutions that benefit their clients at every stage of their operations. After seven years of supplying ABB robots, they have now qualified to become ABB Australia’s latest Authorized Value Provider (AVP).

“We take pride in our own in-house team of skilled engineers, installation, commissioning, and services experts - who are complemented by our solid network of technology and machining consultant suppliers, like industry leader ABB. The systems we’ve delivered have helped our clients to improve precision and consistency, enhance safety for human workers, lower operational costs, and equip them with more flexible operations,” said Murray.

Using ABB’s industrial and collaborative robots, JH Tester has designed and engineered built-to-spec projects that have been deployed in a broad range of companies, including one of the most recognisable oral care brands, a global pharmaceutical company, and the CSIRO. The systems feature advanced robot programming to manage reliable and efficient product inspection, or precise pick and place operations. Some systems have helped clients to increase productivity by up to 400% and bring their operations back to Australia.

Murray explains the observed impact ABB robots have had on their business. “We’re honoured to play a part in supporting Australian businesses. Our clients often share their challenges as they continue to address the skilled labour gap in the manufacturing industry. Thanks to our cutting-edge systems, they can effectively tackle this issue head-on, reduce downtime, and simultaneously increase production output.”

As an ABB Robotics AVP, JH Tester will benefit from expert support via both local and global specialists. Additionally, they will have access to ABB’s RobotStudio®, an offline programming and simulation tool offering users advanced robot programming and optimisation for testing, validation, and visualisation. This comprehensive support ensures AVPs are equipped with the resources to drive success in their projects and operations and deliver faster implementation of solutions for their customers.

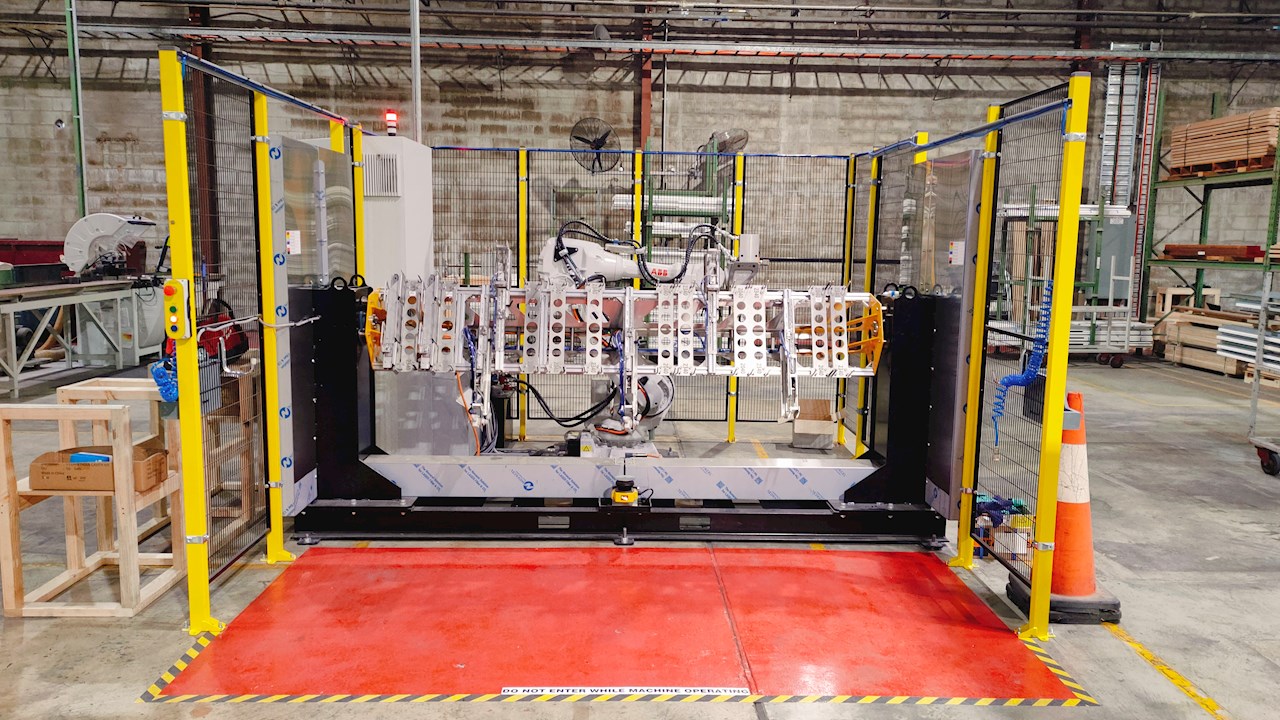

A JH Tester robotic loading system.

Official presentation of the agreement: (L-R): Maria Moraes, JH Tester Project Manager; Murray Tester, JH Tester CEO; together with Peter Katsos, Head of Robotics for ABB Australia and New Zealand.

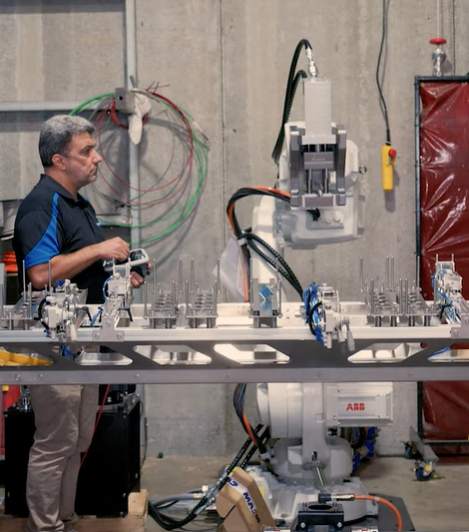

A JH Tester robotic platinum cavity system, designed to process internal cavities in manufacturing applications to reliably check for defects and remove contaminants from internal cavities of castings or molds.

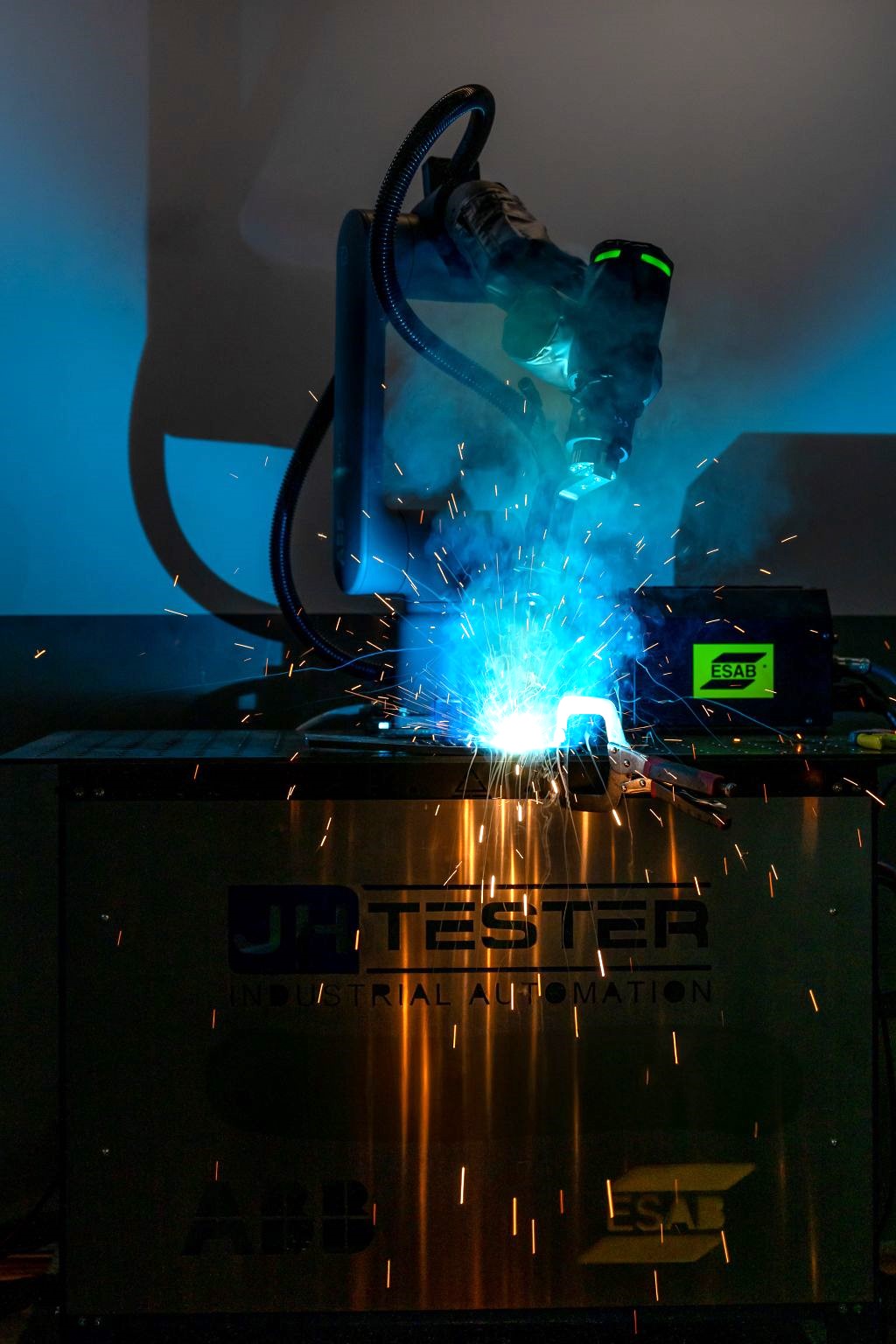

A JH Tester robot welding system featuring ABB’s GoFa collaborative robot.

A JH Tester robot welder in action.

"ABB’s robots are not only an industry standout ... but the strength of the ABB brand also aligns perfectly with our own commitment to innovation."

“Becoming an AVP was a natural next step for us. ABB’s robots are not only an industry standout as a high-quality product that’s easy to operate, integrate, and maintain, but the strength of the ABB brand also aligns perfectly with our own commitment to innovation.

With clients who depend on forward-thinking recommendations and a fast turnaround, the consistent product availability, reliable support, and prompt service received from ABB over the years has undoubtedly optimised the solutions we’ve been able to provide. Once our clients have determined they want to proceed with a project, the focus instantly shifts to how efficiently and reliably we can engineer the system for them – and fast. That’s why it’s critical for all these factors to come together seamlessly,” said Murray.

The future looks even more promising for JH Tester as Murray reveals their next major project - developing a robotic automation solution to support the evolution of the construction industry. Using advanced prefabrication techniques, the project aims to enable more sustainable, modular building practices.

“We’re incredibly excited to support construction businesses in reducing both construction time and costs by assembling components off-site prior to installation in commercial buildings. Furthermore, our systems will empower these businesses to produce scalable structures that they can deploy nationwide. Prefabricated techniques are clearly emerging as the future of construction in Australia,” said Murray.

Peter Bradbury, Channel Manager for ABB Robotics Australia and New Zealand, said, “I’m thrilled to continue working with Murray and his team as we enter this next chapter of our partnership. I’m certain they’ll gain an even greater platform to showcase their accomplishments on a deeper scale, building on the international recognition they’ve already begun to achieve.”

Murray concluded, “Our mission is to revolutionise the manufacturing industry by providing innovative and sustainable automation solutions. We are confident that with the support of partners like ABB, we’ll no doubt continue to do exactly that.”

Discover more of JH Tester's work: The in-house team at JH Tester designed and implemented this custom automation system to replace a previously manual production line—enabling their client to boost output by up to 400%. In this video, an ABB robot is being programmed with precise monument positions as part of the setup. The system not only delivers increased efficiency and accuracy, but will also support the client’s goal of reshoring production back to New South Wales.