As the pulp and paper industry navigates a landscape increasingly fraught with environmental, economic, and social challenges, the call for innovative solutions has never been more urgent. Companies within this sector are setting ambitious goals to reduce emissions, conserve resources, and enhance productivity while maintaining profitability. This transformative journey is being accelerated by digitalization, which is emerging as a cornerstone of sustainability and operational excellence.

Envisioning Tomorrow’s Pulp and Paper Industry

To harness the true potential of digital technology, pulp and paper producers must begin with a vision that prioritizes sustainability alongside operational efficiency. This dual focus entails several key strategies:

Sustainable Solutions: By implementing advanced energy management systems, companies can monitor and optimize energy usage in real-time. This not only helps in reducing CO2 emissions but also minimizes chemical consumption and water usage, ensuring operations remain economically viable.

Optimized Operations: Leveraging cutting-edge automation and digital tools helps companies reduce waste, minimize downtime, and stabilize production profiles. This leads to consistently high-quality output and positions firms to meet the evolving demands of the market.

Integrated Systems: Achieving a comprehensive view of operations necessitates integrating data from disparate systems into a single, cohesive platform. This integration empowers decision-makers to make informed, data-driven choices, enhancing overall asset performance. However, realizing these goals requires more than just adopting technology; it calls for collaboration with a network of ecosystem partners. Striking a balance between short-term improvements and long-term aspirations is essential to drive meaningful change.

Transforming the Pulp and Paper Industry Starts with Vision

Optimizing energy management, automating processes, and enhancing system integration are not just isolated efforts; they are interconnected strategies that collectively contribute to operational excellence. Working alongside leading ecosystem partners, companies can leverage industry expertise to guide their digital transformation initiatives effectively.

Integrating Data Across All Layers:

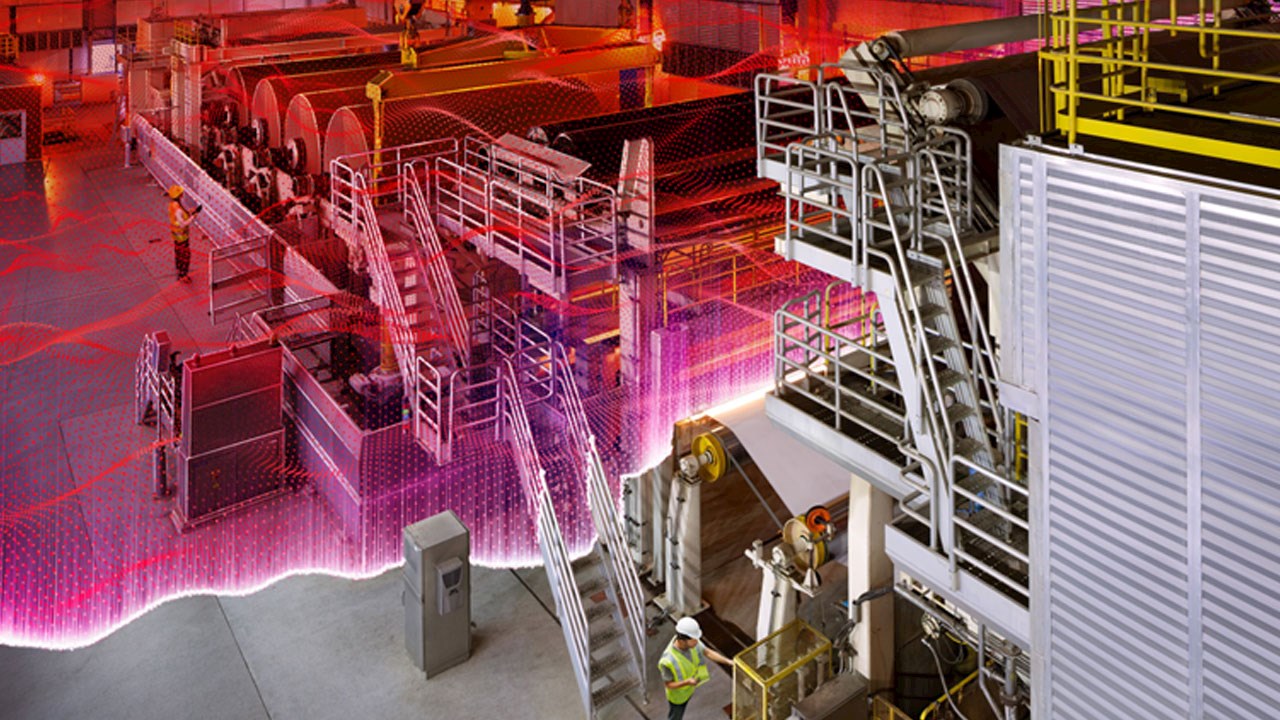

In today’s fast-paced environment, pulp and paper industry leaders require full-spectrum visibility and control. This means swiftly adapting to fluctuating material costs, navigating regulatory demands, and overcoming supply chain challenges. To maintain a competitive edge, integrating data across all operational layers—from machinery and processes to enterprise systems—is crucial. While pulp and paper mills generate vast amounts of data, converting this into actionable insights necessitates careful management. Data must be prepared to interface efficiently with both cloud platforms and the production floor in real-time. Without reliable, well-organized data, the potential of digital tools remains unfulfilled. The task of merging operational, IT, and engineering data can be complex, especially in settings with diverse and legacy systems. Successfully integrating these varied systems demands expertise in both domain knowledge and connectivity solutions. The unique combination of industry-specific expertise and a deep understanding of both operational technology (OT) and information technology (IT) systems is vital. Ensuring that your data strategy aligns with business goals not only supports secure and efficient data management but also enables scalability.

New Avenues for Innovation and Efficiency

With a solid data foundation established, a world of possibilities for innovation and efficiency becomes accessible. Key priorities include enhancing equipment reliability and ensuring that processes operate at peak efficiency and profitability. To truly optimize performance, organizations should view their assets and processes as interconnected parts of a greater whole. The most significant value emerges when previously hidden correlations are uncovered, allowing for smarter, more strategic decisions. Working collaboratively across the entire value chain empowers real-time engagement and alignment toward shared objectives, optimizing operations while fostering a culture of teamwork and shared purpose.

The Power of Industrial Analytics

Harnessing the power of industrial analytics enables companies to transform raw data into meaningful insights that inform strategic decisions. Organizations that embrace this approach not only enhance productivity and sustainability but also position themselves to thrive in an increasingly competitive and environmentally conscious market.

Digital Solutions in the market

In the pulp and paper industry, where the demands of sustainability, efficiency, and resilience are ever-growing, companies are increasingly looking to ABB for cutting-edge digital solutions. Whether it’s enhancing cyber security, optimizing process performance, or driving sustainability efforts, ABB provides the expertise and tools needed to navigate the complex digital landscape.

With a myriad of vendors and solutions available, it can be challenging for decision-makers to choose the right path forward. To help companies navigate the complex landscape and pursue programmes that deliver on value, ABB has developed a digitalization roadmap that rests on five areas, or "value pillars".

The chosen five solution areas - sustainability, asset performance, process performance, operational excellence and a connected workforce - together can be used to provide demonstratable evidence that digital transformation strategies are working.

There is also a horizontal layer, which is cyber security and is critical across the five pillars.

Operational Excellence

Operational excellence in the pulp and paper industry revolves around seamless production management, enhanced quality control, and optimized order-to-delivery processes. This includes integrating different operational areas, from production to logistics, to achieve greater transparency and efficiency across the mill.

Sustainability

Sustainability in the pulp and paper industry is increasingly driven by the need to optimize energy consumption, reduce emissions, and ensure resource efficiency. ABB’s solutions enable companies to achieve these goals by providing comprehensive energy management systems that deliver measurable savings and environmental benefits.

Asset Performance

Optimizing asset performance in pulp and paper mills involves shifting from reactive to predictive maintenance strategies. This transition not only helps to avoid unnecessary maintenance but also reduces overall operating costs. ABB’s advanced asset monitoring solutions provide the tools needed to achieve these goals.

Process Performance

Optimizing process performance in pulp mills involves enhancing product quality, reducing variability, and improving overall efficiency. ABB’s advanced process control solutions help mills achieve these goals by integrating predictive control and soft sensors into their operations.

Connected Workforce

In the pulp and paper industry, having a skilled and well-trained workforce is crucial for maintaining safe and efficient operations. ABB Ability™ Industrial Knowledge Vault, a generative AI-driven solution designed to solve the growing challenge of knowledge loss in industrial environments. Industrial Knowledge Vault, using Microsoft Azure OpenAI Service, can store, retain and safeguard critical expertise while actively transforming that knowledge into step-by-step workflows. This enables workers to quickly access and apply best practices, empowering businesses to run leaner while preserving safe operations.

Cyber Security

In an increasingly connected world, ensuring robust cyber security is essential for maintaining safe and reliable operations in the pulp and paper industry. ABB’s comprehensive cyber security solutions safeguard mill operations from potential threats, ensuring continuity and resilience.

Bringing it all together

The conversation around digital transformation is central to driving progress in the pulp and paper industry. As operations grow more complex, mastering advanced technologies and industry-specific processes, while ensuring robust cyber security, becomes crucial. Supporting mills from design through to system commissioning and maintenance is key to achieving sustainable success.

Harnessing the power of industrial analytics enables companies to transform raw data into meaningful insights that inform strategic decisions.

In today’s fast-paced environment, pulp and paper industry leaders require full-spectrum visibility and control.

Mills that embrace digital solutions can expect significant rewards: enhanced efficiency, reduced environmental impact, and improved supply chain management. By standardizing processes, mills can reduce complexity while boosting overall performance.

ABB is pivotal in this transformation, providing a unified system that bridges the gap between the shop floor and the top floor. This integration strengthens your continuous improvement cycle, ensuring that every aspect of your operation benefits from the latest technological advancements.

As energy efficiency and sustainability become increasingly critical, particularly for energy-intensive industries like pulp and paper, ABB is rapidly developing new digital tools. These innovations are created in collaboration with customers, academic institutions, and other ecosystem partners.