Fred, before we dive into the topic – do you remember when and how you first came into contact with a frequency converter?

Yes, I remember it well. It was during my electrical engineering studies at the University of Karlsruhe, especially in my diploma thesis. I worked on programming field-oriented control – or in other words, vector control for asynchronous machines – focusing on the motor model as well as current and speed control. That’s part of the frequency converter software used for precise and dynamic motor control, still applied today.

Which technical developments in recent decades have impressed you the most? Were there real breakthroughs?

From my point of view, there have been many great developments in both hardware and software. Numerous innovations have been introduced, such as very compact, installation-friendly, and extremely high-quality hardware. Software has also become much more user-friendly and flexible over the years. I’m thinking of IEC 61131 programming or the new ABB Crealizer as a perfect addition for customer-specific control tasks or data analysis.

A real milestone was the introduction of Direct Torque Control (DTC) in our ACS600 drives in 1995. This took performance to a completely new level, particularly for controlling AC motors without encoder feedback.

What were the biggest challenges in developing or applying frequency converters – and how were they solved?

One challenge was achieving or surpassing the control performance of DC machines with the first generations of drives. For a long time, DC drives were very widespread. Building acceptance for the new technology required a lot of persuasion.

Early AC drives also pushed the limits of the analog and digital technology available at the time. But the advantages of controlled AC drives continuously drove development forward.

Today, we have devices with an extremely high level of control performance – in fact, the line between an AC drive with a frequency converter and a servo system has become blurred. This opens up new opportunities in plant optimization and productivity.

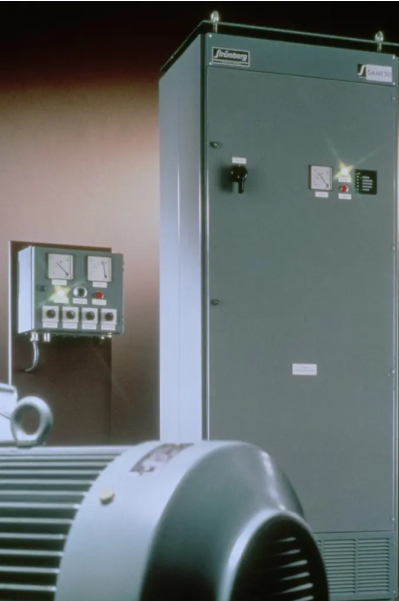

The first drives were very large compared to today’s models. If you place a drive from the 1970s next to a modern one, the difference is striking. The introduction of modern IGBT semiconductor technology and the powerful microelectronics have made today’s drives much more compact.

Which industries or applications do you think have benefited most from variable speed AC drives?

In my opinion, all industries have benefited from AC drive technology – machine building, process industries, water/wastewater, HVAC, and many more. Modern variable speed drives offer significant energy-saving potential, make industrial processes more flexible, and improve both output and product quality. The use of variable speed drives brings so many benefits that companies today cannot do without them – and they strengthen competitiveness.

How has the technology – or its environment – changed since you started?

I’ve been with ABB since 1992, and a lot has changed. Energy efficiency and sustainability are much more in focus today than in the past, and willingness to invest in new technology has increased, not least due to high energy prices. But there’s still room for improvement – many uncontrolled motors in industry still consume too much energy.

The devices themselves have become much more user-friendly. Like a new TV, today’s drives ask a few questions during setup and then handle much of the process automatically. Within minutes the motor is running, without needing to be an expert.

Another aspect is system integration. In the past, it was mostly digital/analog signals or simple serial interfaces. Today we use various fieldbuses, including the latest Industrial Ethernet solutions such as PROFINET or EtherCAT. The current trend is towards OPC UA, which makes it easy to transfer valuable data from the drive to higher-level systems.

And of course, machine safety. Compared to older devices, today’s drives include many integrated safety functions, which make machine design much easier for customers. Safe Torque Off is now standard, with many optional safety functions that keep machines safe and protect the people working with them.

Is there a project that has particularly stayed in your memory?

Yes, my first commissioning assignment was very exciting. We had problems because data communication was being sporadically disrupted. That’s frustrating, because it means the system doesn’t run properly. Colleagues from the development department ABB Finland came to help us with troubleshooting. They brought the necessary diagnostic tools and had deeper insights thanks to their development tools. The problem was identified and solved. That’s one of our strengths: solving challenges together as a team.

Do you have an anecdote you like to tell about electric drives?

Yes, one amusing story comes to mind. Years ago, ABB headquarters forwarded a call to me from an elderly lady who had a problem with her electric drive. I asked what exactly the issue was, which drive she had, and what power rating. She replied that the drive in her kitchen extractor hood had stopped working. The hood was labeled BBC, which she assumed was now ABB. Unfortunately, I couldn’t help her with our industrial drives – and given the age of the hood, a replacement seemed the best option.

What advice would you give young colleagues working with drives?

Today, it’s no longer enough just to know power electronics or motor control. The field is very broad, and that’s what makes electric drives so exciting. You learn a lot about customers, applications, machines, and plants. And there are always new developments and applications in drive technology. I’m curious to see what new semiconductors and AI will make possible in the future. Drive technology is very much on-trend and continues to grow.

Electrical engineering is a fascinating field, and I am still passionate about it – especially drive technology, because it combines so many aspects. You can contribute in many directions – power electronics, electronics, engineering, programming, digital communication, apps, functional safety, EMC, and above all energy efficiency. The range is huge, offering strong motivation for young professionals.

What are your wishes for the future – for the technology, for ABB, and for the people working in this field?

I hope ABB will continue to be a global leader and even expand this position, while also opening up new application areas. I also hope that with our technology we can make life easier for people, conserve valuable resources, and make an important contribution to CO₂ reduction and climate protection – ideally with a good dose of fun and enthusiasm along the way!