- High-thrust capacity for demanding applications

- Easy maintenance with direct pump shaft access

- Drop-in design simplifies installation and replacement

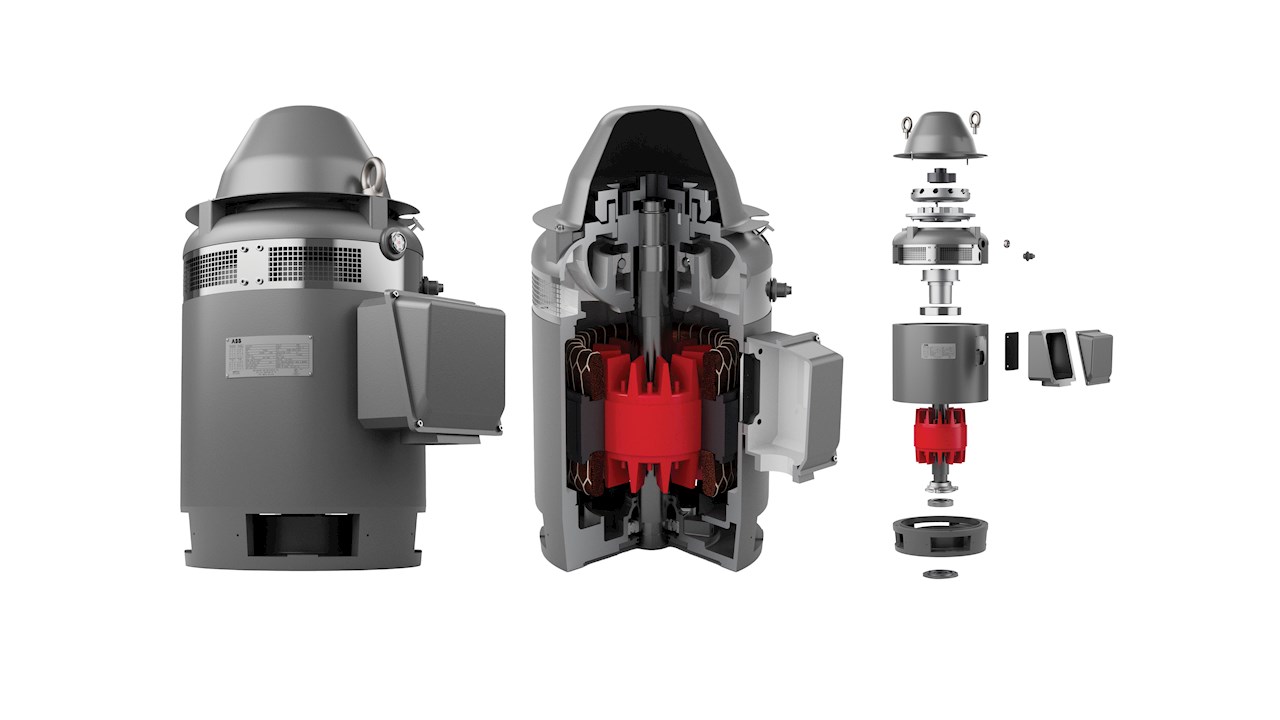

ABB’s line of vertical hollow shaft (VHS) motors is engineered specifically for vertical turbine pump applications in industries where performance, reliability and longevity are critical, reflecting ABB’s commitment to innovation, energy efficiency and customer-centric engineering.

These motors include a sight glass for oil inspection, a top-mounted coupling, and a hollow shaft that allows quick access to the pump shaft, which minimizes downtime and expedites routine maintenance. Designed for efficient and reliable operation as well as ease of maintenance, VHS motors incorporate NEMA Premium® (IE3)* efficiency, high-thrust capability and drop-in design compatibility, providing solutions for water, agricultural and industrial pumping systems that require durability and straightforward service.

“ABB vertical hollow shaft motors are purpose-built to elevate operations across multiple industries,” said Terry Bell, ABB Product Manager. “From irrigation systems to municipal water supply, these motors offer unmatched reliability and performance, helping customers reduce maintenance and overall operational cost.”

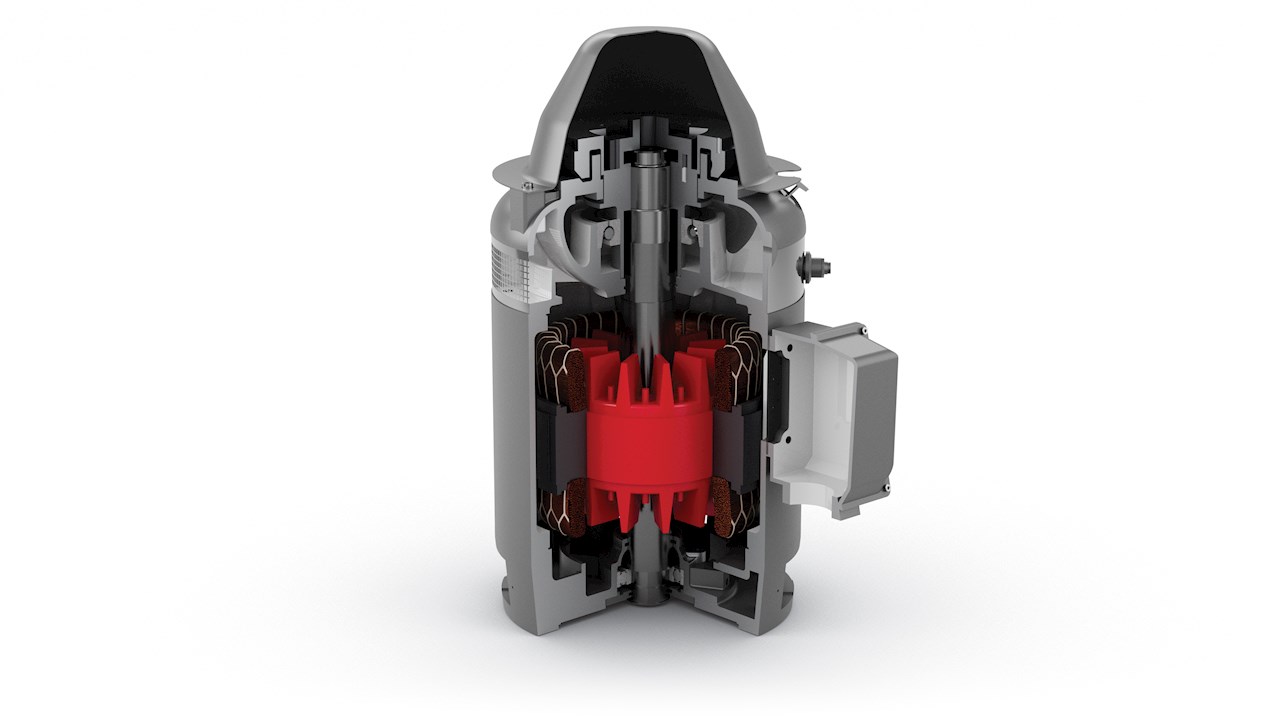

ABB VHS motors are engineered with heavy-duty, extra high-thrust bearings designed to withstand the intense axial loads of deep well and vertical turbine pumps - delivering stable, long-lasting performance. They feature a hollow shaft and top-mounted coupling, allowing fast, direct access to the pump shaft without removing the motor - reducing service time, simplifying alignment and minimizing downtime for operators and maintenance teams.

Designed to match industry-standard dimensions, ABB’s VHS motors offer a true drop-in fit for vertical pump applications - minimizing installation time and making them ideal for new builds or motor replacements.

Key features

- NEMA Premium (IE3) efficiency - Delivers consistent torque and energy savings

- Extra high-thrust capacity - Machined for 175% extra thrust on 360 frames and above; double-stacked bearings on 440 frames and above

- Stationary and non-reverse ratchet that prevents reversing due to backspins

- Standard NEMA P-base flange that allows for easy drop-in replacement of existing motors

- Inverter duty rated - Compatible with modern variable speed drives

- User-friendly design - Top-mounted coupling for easy shaft and impeller access; oversized conduit box and sight glass for simplified maintenance

- Durable construction - Heavy-duty cast iron frame, UL Listed and Weather Protected Type 1 (WP1) rated

- Wide range of configurations - Available from 15-500 Hp with multiple voltage and frame options

Applications

- Deep well vertical turbine pumps

- Agricultural irrigation systems

- Municipal water and wastewater systems

- Industrial cooling towers

- Fire protection systems

With decades of innovation behind every unit, ABB VHS motors combine trusted durability with advanced engineering - driving water, energy and industry forward with confidence.

*NEMA Premium efficiency is generally comparable to IE3 efficiency for AC induction motors operated direct on line (DOL) as defined by the International Electrotechnical Commission (IEC).

ABB Motion, a global leader in motors and drives, is at the core of accelerating a more productive and sustainable future. We innovate and push the boundaries of technology to contribute to energy efficient, decarbonizing and circular solutions for customers, industries and societies. With our digitally enabled drives, motors and services we support our customers and partners to achieve better performance, safety and reliability. To help the world’s industries outrun – leaner and cleaner, we deliver motor-driven solutions for a wide range of applications in all industrial segments. Building on over 140 years of domain expertise in electric powertrains, our more than 22,000 employees across 100 countries learn and improve every day. new.abb.com/motion

ABB is a global technology leader in electrification and automation, enabling a more sustainable and resource-efficient future. By connecting its engineering and digitalization expertise, ABB helps industries run at high performance, while becoming more efficient, productive and sustainable so they outperform. At ABB, we call this ‘Engineered to Outrun’. The company has over 140 years of history and more than 105,000 employees worldwide. ABB’s shares are listed on the SIX Swiss Exchange (ABBN) and Nasdaq Stockholm (ABB). www.abb.com