At the edge of the Mojave Desert, where freight trucks thunder up and down the I-10, a quiet revolution is underway. The new charging station in Colton, California — built by Greenlane Infrastructure and powered by ABB technology — is more than just a truck stop.

It’s a prototype for how the U.S. freight industry might finally go electric.

This site is the first in a planned national network of high-performance electric charging and hydrogen refueling stations. But to make those sites viable, Greenlane had to answer a question that looms large for anyone in the EV freight space:

Can charging an electric truck be as fast and convenient as diesel — without overwhelming the grid?

A truck stop built on tough questions

From the start, Greenlane knew the destination, but not the full route. They shared their operational challenges—from unpredictable charging demand to grid capacity constraints—and collaborated with ABB to define the right approach. Together, we developed a system designed not just to work today, but to grow with tomorrow’s technology.

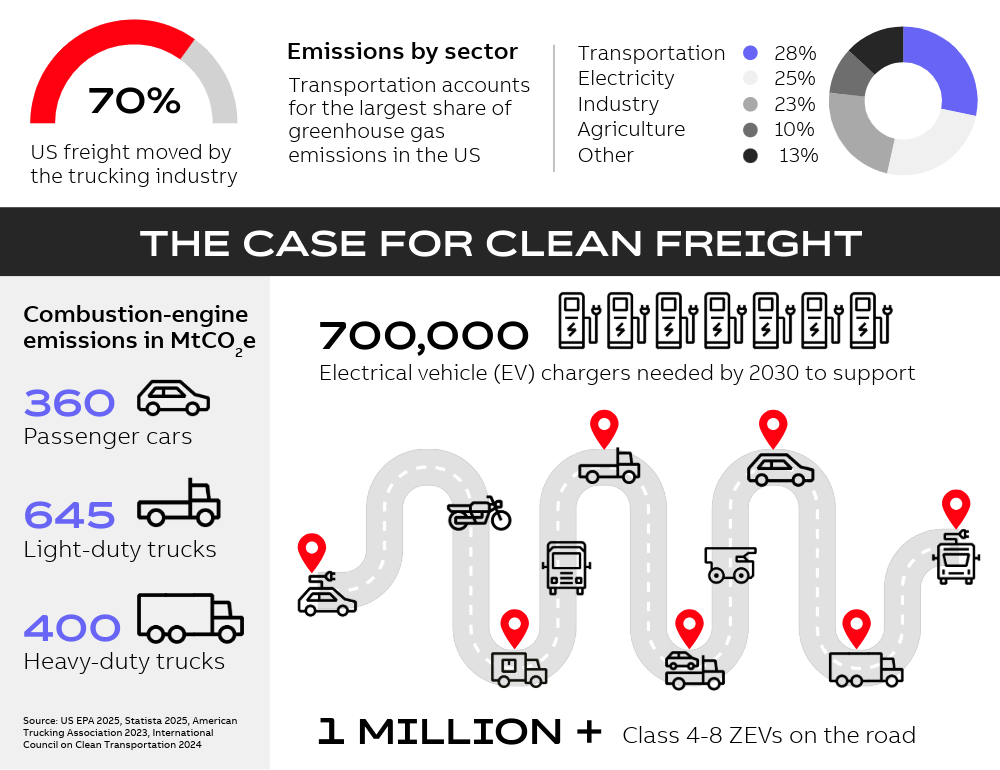

High-speed charging for heavy-duty EVs isn’t like charging a car. The power demand is exponentially higher and requires thoughtful load management to avoid tipping the grid into instability.

In lieu of massive new grid connections, the Greenlane-ABB team focused on intelligent energy management to use existing power more effectively.

ABB delivered a SCADA-based control system that coordinates all major site loads — from chargers to switchgear — to stay within utility thresholds and avoid blackouts. If power demand gets too high, the system automatically scales back power to certain chargers, starting with slower overnight units and only dialing back the fast chargers if absolutely necessary.

It’s a dynamic, invisible system that lets Colton operate within its grid allocation while preparing to add solar and battery storage and ultimately take the next big leap: Megawatt Charging Systems (MCS) that can deliver 300 miles of range in 30 minutes, aligned with truckers’ federally mandated rest breaks. The site is fully futureproofed to integrate all three technologies as market needs evolve.

Staying online without always being on-site

Sounds easy? It is with the right system in place.

When you're planning a nationwide network, staying in control—without being physically present at every location is a top priority.

WIth ABB’s remote switching capability, Greenlane operators can safely open and close breakers across both low- and medium-voltage systems, without being on-site: a rarity in EV charging today Access is tightly controlled, with permission restricted to authorized operators.

Real-time alerts, sent via email or SMS, provide instant visibility into what’s happening on the ground. And with centralized oversight, Greenlane can scale its network without scaling its field teams. reducing operation & maintenance costs and improving response times.

Lessons from Colton: a framework for freight electrification

Colton offers a model others can adopt, based on a few essential principles:

- Start with limits: Design for today’s grid, future-proof for tomorrow’s upgrades.

- Build in flexibility: Use modular systems that support solar, battery storage, and MCS as needs evolve.

- Operate smart and safe: Enable remote visibility and control to reduce downtime and support future growth.

What’s next

Greenlane plans to open additional stations along the LA–Vegas corridor and beyond, building the confidence freight operators need to transition to EVs at scale.

Their first customer, electric-only freight company Nevoya, is already running trucks out of the site—proving that when infrastructure is designed with real-world logistics in mind, electric transport doesn’t just work.

It works better.