- Launch of OmniCoreTM EyeMotion and Automatic Path Planning Online mark milestones on ABB’s journey to Autonomous Versatile Robotics – AVRTM

- China debut of IRB 6750S shelf robot: powerful, precise, space efficient automation

- ABB “In China, for China” strategy showcased by locally produced IRB 1200 Gen 2, PoWa cobot, IRB 1100 Lite+ and new IRB 920: delivering essential material handling to high-end applications

ABB Robotics is showcasing the future of robotics at the 25th China International Industry Fair (CIIF 2025), furthering its journey towards truly Autonomous Versatile Robotics (AVRTM).

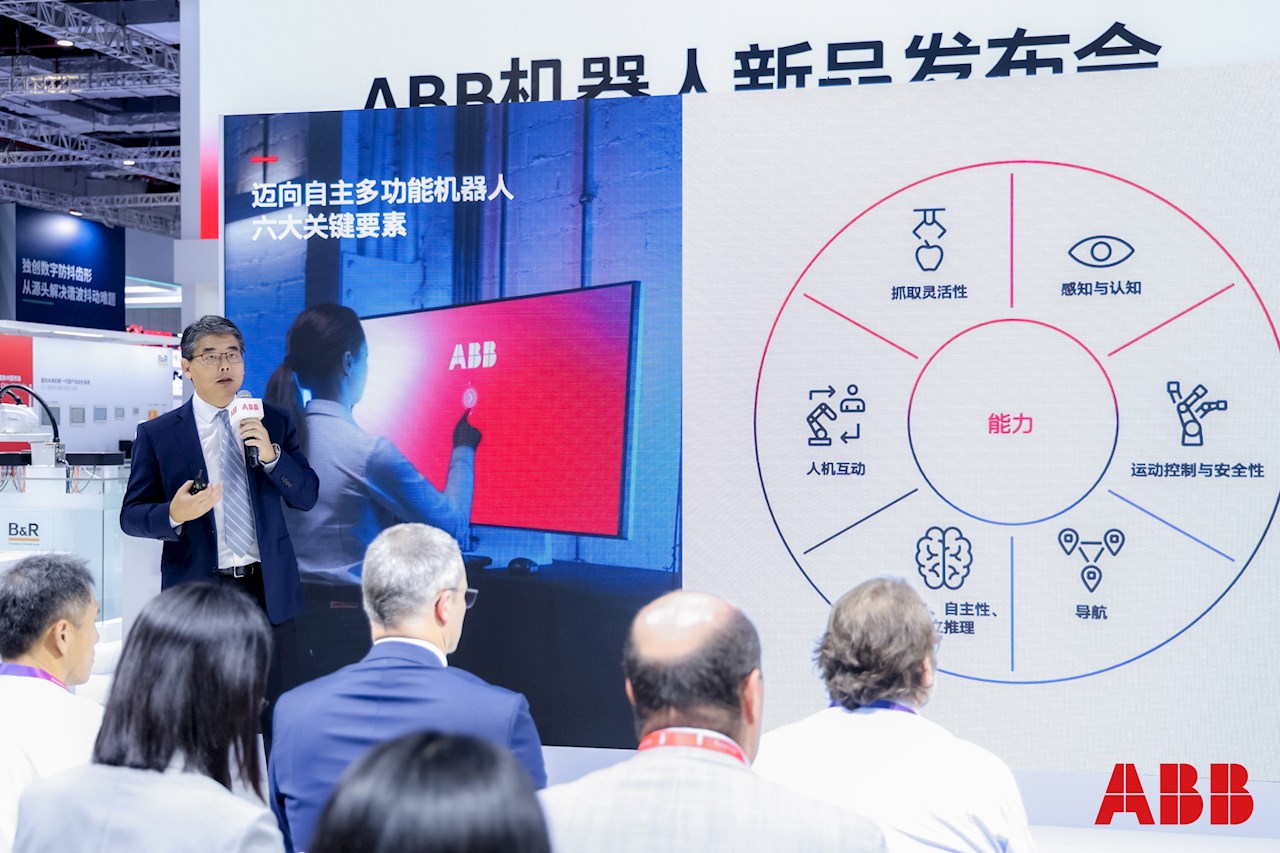

“We stand at a pivotal moment in the evolution of AI and industrial robotics. Over the past decade, we’ve given robots eyes through 3D AI vision; hands through advanced force-sensing and precision dexterity; and mobility through autonomous navigation.” said Marc Segura, President of ABB Robotics. “Today, we are bringing these capabilities together in new ways - through technologies like OmniCoreTM EyeMotion and Automatic Path Planning Online - to redefine industrial robotics. These innovations allow robots to perceive, understand and navigate in complex environment with unprecedented autonomy.”

"As the world's largest robotics market, China is leading the wave of industrial transformation. With our ’in China for China' strategy, we continue to accelerate world-leading technologies in the Chinese market," said Henry Han, Group Senior Vice President and President of ABB Robotics Division in China. "These innovations address the growing demands of Chinese customers of all sizes for more flexible and intelligent solutions and are possible because of our full local value chain in manufacturing, research and development, supporting China's progress in advanced manufacturing.”

Advanced Technologies for an Autonomous Versatile Future

The new technologies on show at CIIF 2025 are essential in bringing to life ABB Robotics’ vision for Autonomous Versatile Robotics (AVRTM). In a new generation of robots, ABB will bring together advanced capabilities including AI vision, precision, speed, dexterity, and mobility, fused by the power of generative AI into the autonomous planning and execution of a diverse range of tasks, seamlessly and in real time, without human intervention.

OmniCoreTM EyeMotion

OmniCore EyeMotion gives any OmniCore-powered robot powerful sensing and perception capabilities. With this integrated intelligence, robots can recognize their surroundings using any third-party camera or sensor.

OmniCore EyeMotion can be further combined with ABB’s unique Automatic Path Planning Online, which can plan and execute the optimum, collision-free paths around obstacles and moving objects in real time, continually and without human intervention, increasing autonomy and reducing cycle times up to 50 percent in key tasks such as pick and place.

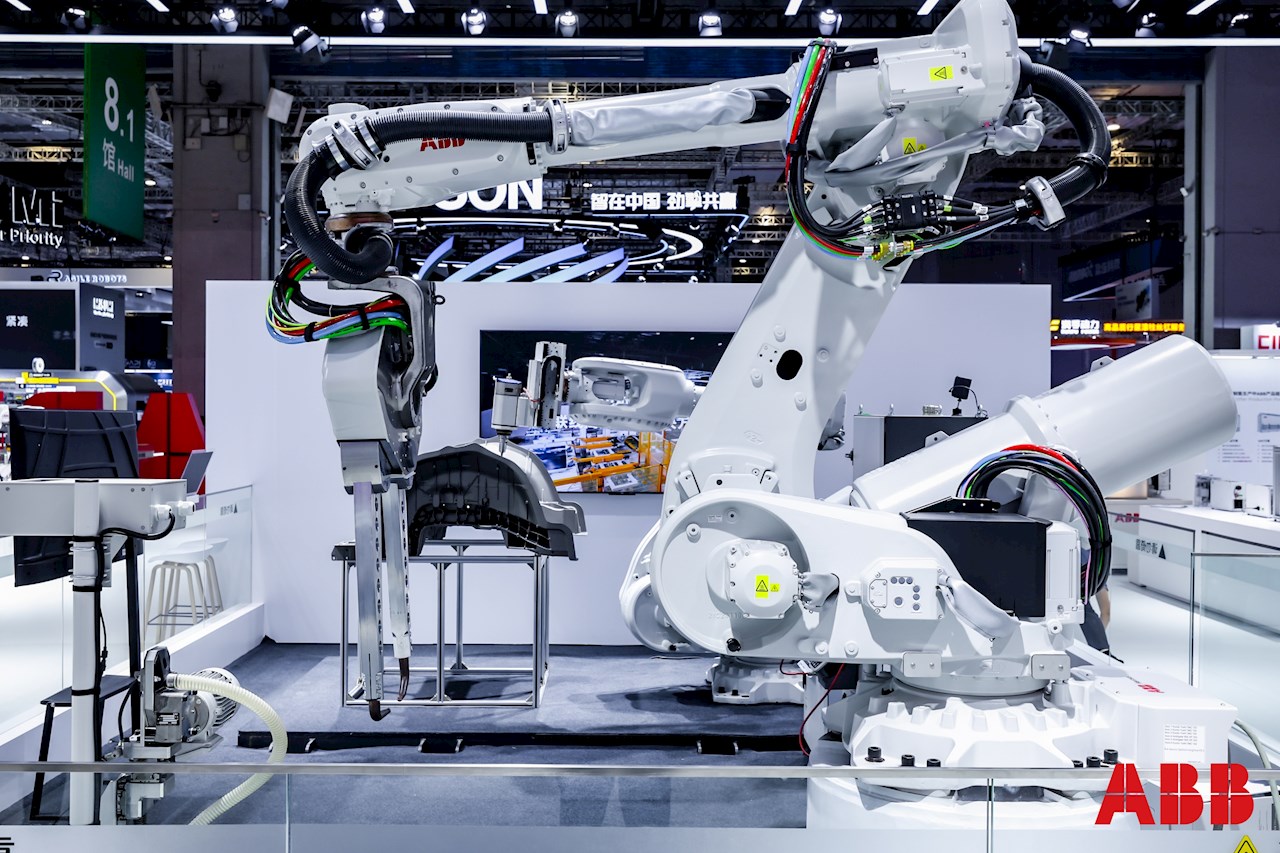

New IRB 6750S: Powerful, Precise Automation in Any Location

The new IRB 6750S ‘shelf robot’ brings a superior payload capacity of up to 350kg, class-leading path accuracy of 0.9 mm and position repeatability of 0.06 mm to new spaces and locations.

It can be installed at heights above floor level, with full vertical and horizontal motion to increase downward reach, ideally suited to increasing productivity and throughput in tasks such as material handling, die casting and spot welding.

Combined with ABB’s OmniCoreTM smart controller platform, IRB 6750S also consumes 20 percent less energy than its predecessor.

Made In China, For China: new IRB 920, PoWa, IRB 1200 Gen 2 & IRB 1100 lite+

ABB brings new robot innovations to CIIF, made in China for Chinese customers, which build on over 30 years of market leadership in the country.

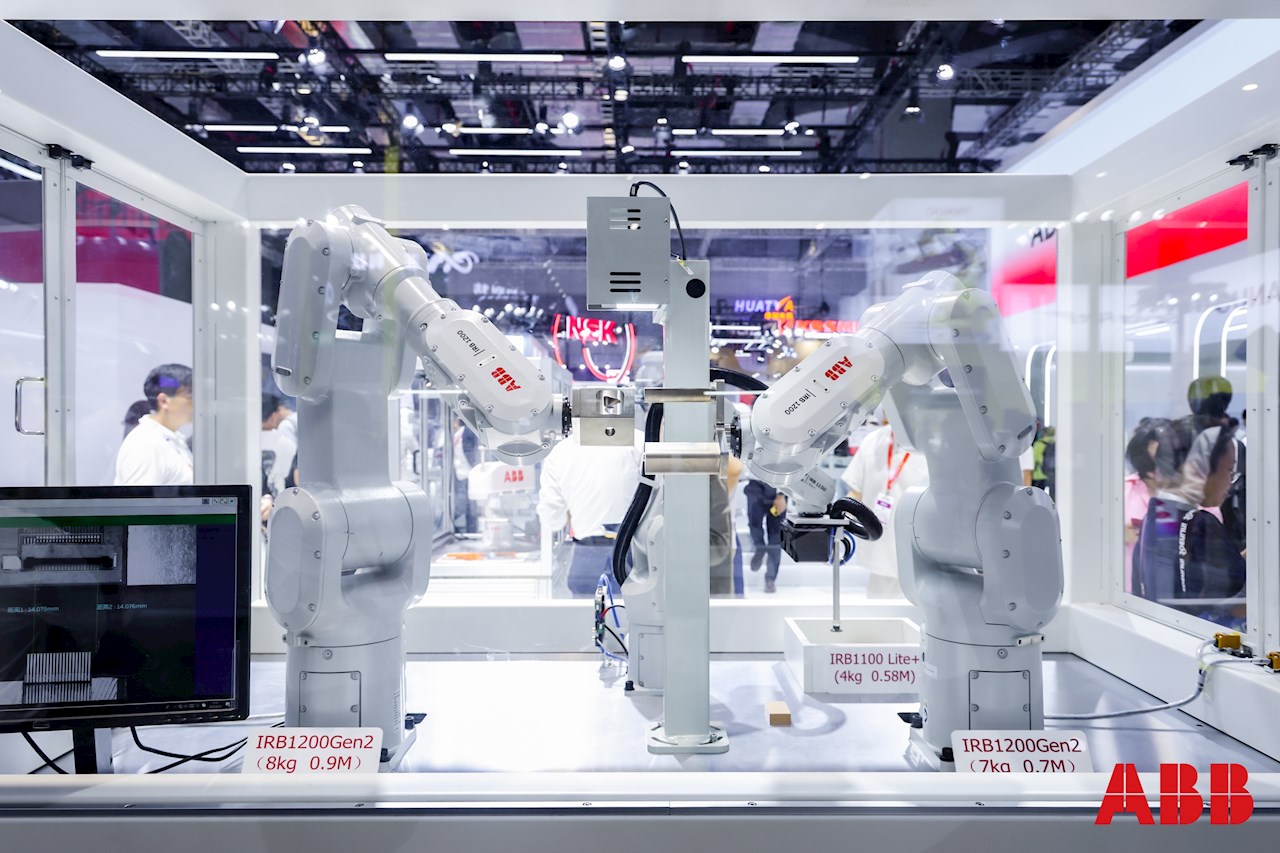

Designed, engineered and manufactured in China, to address the specific needs of customers in China and the wider Asia Pacific region, the extended portfolio covers customer needs from essential to high-end applications.

Making its debut at CIIF 2025, the new IRB 920 will demonstrate superior motion control and performance in confined spaces, through its new short-arm configuration, payload capacity of up to 6kg and reach of 0.45m - developed in direct response to Chinese customer demands for a smaller footprint and shorter reach. Beyond China, IRB 920’s new variant will be an addition to ABB Robotics’ global SCARA robot family.

ABB’s newly launched PoWa cobot family will demonstrate flexibility in handling, combining high-speed performance with collaborative capabilities in a compact design.

For industrial applications, IRB 1200 Gen 2 & IRB 1100 Lite+ will show their complementary, flexible solution for automating multiple stages in electronics manufacturing, from material handling to high-speed assembly. All are produced at ABB Robotics’ state-of-the-art Shanghai Mega Factory, which embodies its vision for smart, flexible production and its commitment to support China’s progress in advanced manufacturing. Over 90 percent of ABB robots for Chinese customers are made in China.

As the first foreign company to offer the full value chain in China – from research, to production, sales and service – ABB also supports customers locally, through its nationwide service network covering 22 cities.

ABB Robotics & Discrete Automation as one of the world’s leading robotics and machine automation suppliers, is the only company with a comprehensive and integrated portfolio covering robots, Autonomous Mobile Robots and machine automation solutions, designed and orchestrated by our value-creating software. We help companies of all sizes and sectors - from automotive to electronics and logistics – to outperform by becoming more resilient, flexible and efficient. ABB Robotics & Discrete Automation supports customers in the transition towards the connected and collaborative factory of the future, operating leaner and cleaner for a better future. The business area employs approximately 11,000 people at over 100 locations in approximately 53 countries. go.abb/robotics