The challenge

Solema, an Italian company providing automation solutions for the paper and packaging industry, has operated for over 40 years with expertise ranging from book production to packaging. Although many stages of the process have been automated, manual palletizing remained an unresolved aspect in its production line. Operators needed to lift several hundred kilograms of paper during each shift, which was repetitive and physically intensive. This presented ergonomic considerations and impacted on the operator’s ability to concentrate on product quality and production efficiency.

Application Requirements

The goal was to automate palletizing at the end of the production line for corrugated and solid board partitions, while ensuring flexibility to handle other products such as stacks of books, magazines, and boxes. The system needed to work safely alongside operators in a shared workspace, adapt to products of different sizes, and allow quick changeovers for different palletizing patterns without complex reprogramming.

Solution

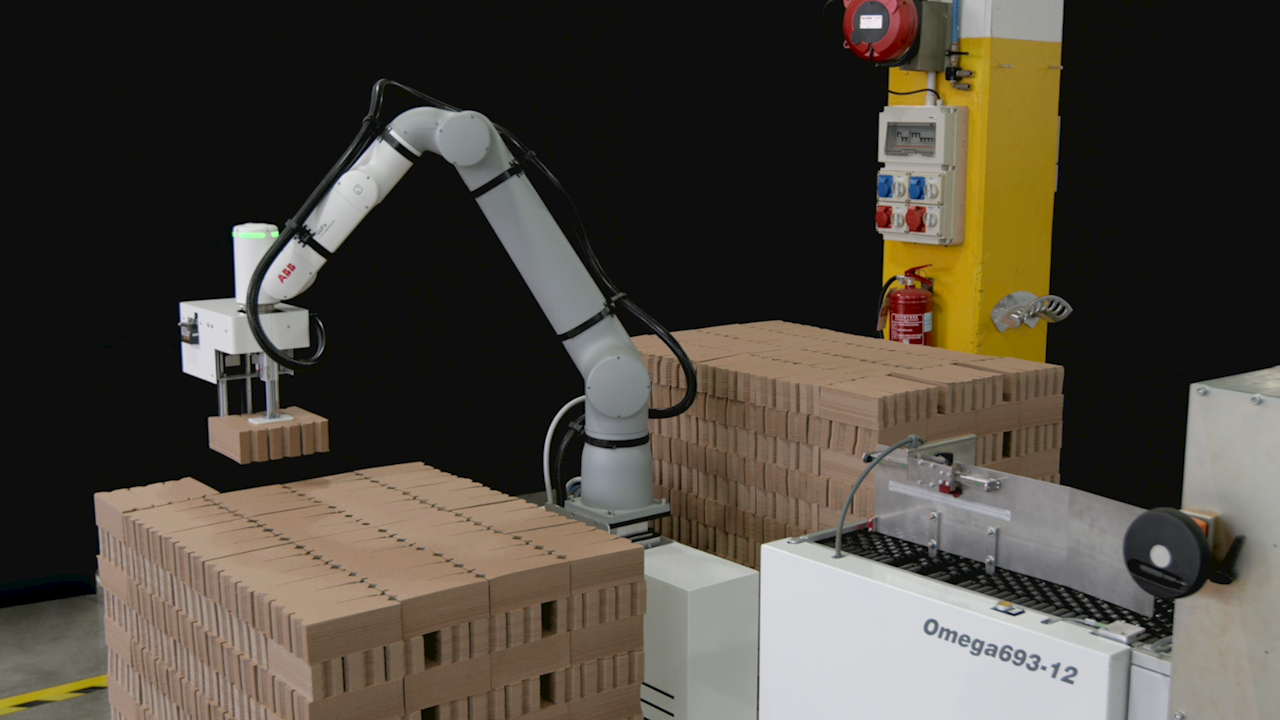

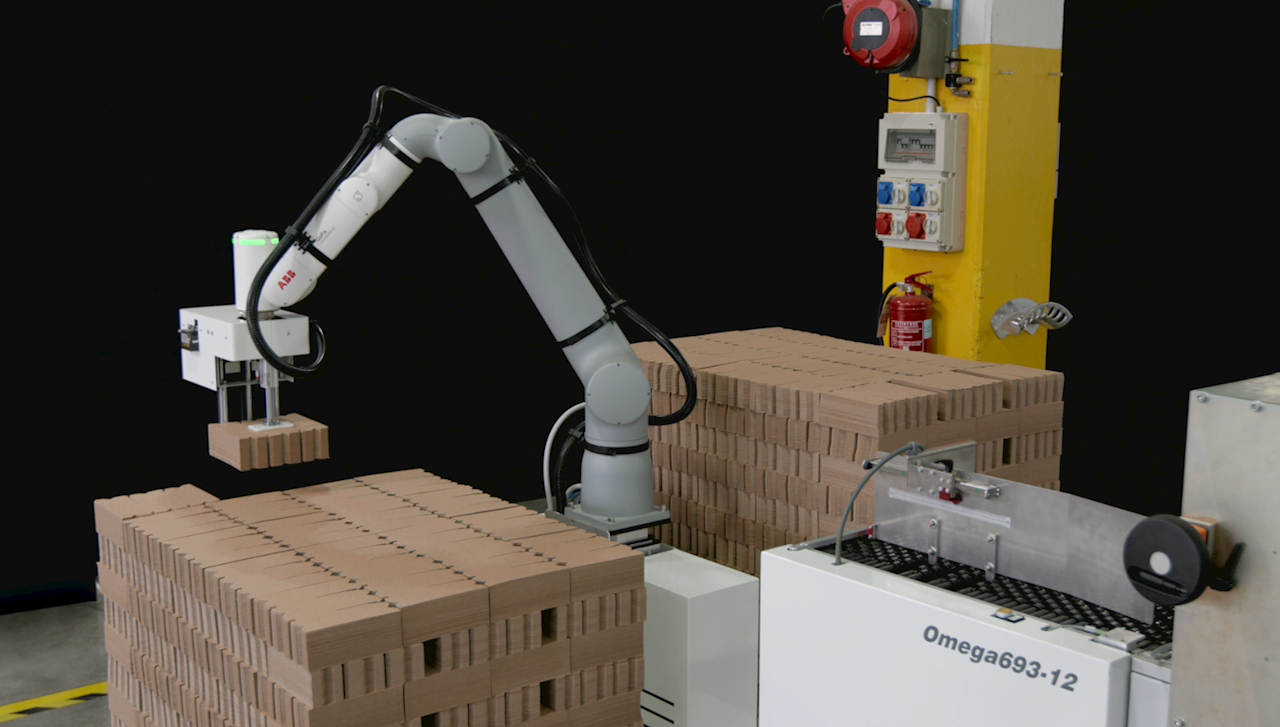

Solema has integrated ABB’s GoFa™ collaborative robot into its Omega 693 palletizing system. GoFa's technical specifications make it highly suitable for collaborative palletizing environments, enhancing palletizing cycles through advanced motion control that ensures precise placement. Its compatibility with a laser scanner safety system further contributes to its effectiveness and safety in collaborative settings. Using ABB RobotStudio®, Solema’s R&D team could simulate the application in advance, refining performance before deployment.

“Years ago, when we ventured into robotics to enhance our automation offerings, we sought a supplier with a strong brand and support structure for both local and international projects. Choosing ABB robotics provided these, along with professional support, flexibility, a well-tested product line, and cutting-edge technologies” Luca Parsani – Head of Business at Solema.

The Omega 693’s dedicated software, accessible through ABB’s FlexPendant, enables end users to easily program and store multiple palletizing applications for various product sizes. The result is precise, orderly palletizing of pallets of different dimensions, with over 20% productivity gains, the operators are relieved from heavy manual lifting and can now focus on higher-value tasks that enhance operational efficiency.

Looking Ahead

This project marks the beginning of Solema’s robotic automation journey. With ABB’s GoFa cobot, the company is already exploring additional automation opportunities for the Omega 693 and other systems, further expanding its capabilities in the paper and packaging industry.

ABB (ABBN: SIX Swiss Ex) is a global technology leader in electrification and automation, enabling a more sustainable and resource-efficient future. By connecting its engineering and digitalization expertise, ABB helps industries run at high performance, while becoming more efficient, productive and sustainable so they outperform. At ABB, we call this ‘Engineered to Outrun’. The company has over 140 years of history and around 110,000 employees worldwide. ABB’s shares are listed on the SIX Swiss Exchange (ABBN) and Nasdaq Stockholm (ABB). www.abb.com

ABB Robotics & Discrete Automation as one of the world’s leading robotics and machine automation suppliers, is the only company with a comprehensive and integrated portfolio covering robots, Autonomous Mobile Robots and machine automation solutions, designed and orchestrated by our value-creating software. We help companies of all sizes and sectors - from automotive to electronics and logistics – to outperform by becoming more resilient, flexible and efficient. ABB Robotics & Discrete Automation supports customers in the transition towards the connected and collaborative factory of the future, operating leaner and cleaner for a better future. The business area employs approximately 11,000 people at over 100 locations in approximately 53 countries. go.abb/robotics