- ABB Kazakhstan celebrated three decades in the country by hosting a customer and partner seminar on September 24–26, 2025, at the BeFine family mountain resort, strengthening relationships with key clients in partner industries.

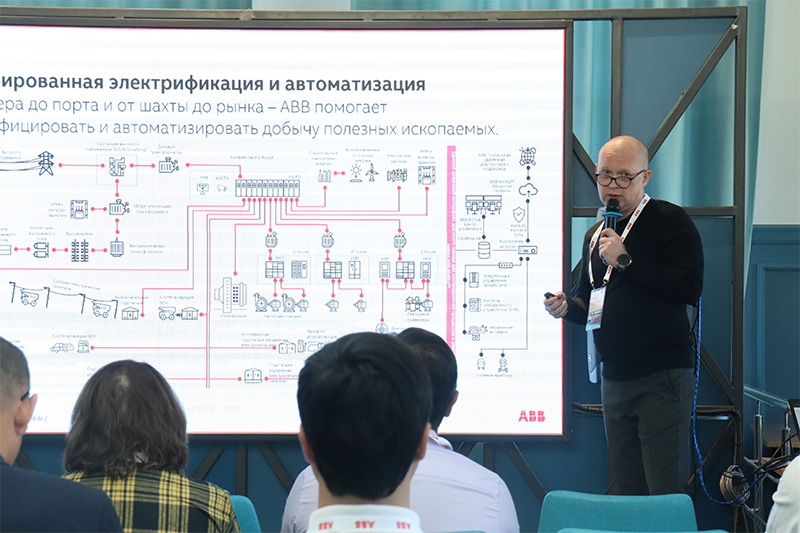

- The seminar featured ABB integrated solutions for the mining industry — from electrification and automation systems to digital tools, advanced drive technologies, and condition-based maintenance solutions. All the innovations presented are engineered to enhance the safety, efficiency, and sustainability of industrial operations.

Held against the scenic backdrop of the Almaty region’s mountains, the three-day seminar served as both a celebration and a forward-looking forum. It marked 30 years of ABB’s presence in Kazakhstan by bringing together clients, partners, and experts in a relaxed setting conducive to collaboration. The agenda was packed with discussions on how ABB’s latest technologies can solve industry challenges, improve operational efficiency, and support the sustainable growth of Kazakhstan’s mining sector. Choosing the BeFine mountain resort as the venue helped create a welcoming and relaxed atmosphere, where participants could connect during group activities, technical sessions, and the formal dinner.

ABB Customer Seminar 2025 Second Day. Image: ABB

Seminar’s coffee break 1. Image: ABB

Seminar’s coffee break 1. Image: ABB

ABB showcased its integrated solutions for the mining industry during a series of expert sessions, demonstrating how the company’s comprehensive technologies support modernization and optimization of production processes. The spotlight was on power supply systems — from high-voltage switchgear and modular e-houses to motor control centers. In collaboration with partners from PSI, ABB experts illustrated how reliable electrification enhances productivity and safety at remote sites. Particular attention was given to ABB’s flagship automation platform, System 800xA, and the digital capabilities of ABB Ability™ MineOptimize, which enable centralized control of all operations through a single interface, delivering real-time transparency and precision for confident decision-making.

Digitalization as a driver of mining transformation was another central theme. ABB presented its ABB Ability™ digital tools, including remote asset monitoring and predictive analytics, which support condition-based maintenance and early detection of equipment issues. The company also showcased its advanced drive and motor technologies engineered for demanding operating conditions: Gearless Mill Drives (GMD), Ring-Geared Mill Drives, and gearless conveyor drives. Sessions on mine hoist systems and advanced motors, led by ABB Finland experts, focused on innovations that increase load capacity and reduce energy use. Finally, ABB demonstrated how smart sensors and monitoring platforms track equipment health in real time, recommending proactive maintenance to extend asset life and maximize uptime.

ABB Customer Seminar 2025 Presentation 1. Image: ABB

BB Customer Seminar 2025 Presentation 2. Image: ABB

ABB Customer Seminar 2025 Presentation 3. Image: ABB

ABB Customer Seminar 2025 Presentation 4. Image: ABB

ABB Customer Seminar 2025 Presentation 5. Image: ABB

ABB Customer Seminar 2025 Presentation 6. Image: ABB

The seminar’s agenda featured a strong line-up of both international and local ABB experts, underscoring the company’s global reach and local dedication. Alex Kaufmann, Cluster Manager from ABB Switzerland, in cooperation with Alireza Oladzadeh, ABB’s global GMD Service Manager, opened the technical program by framing the event’s importance in a regional context. Rustem Sharipov, Area Sales Manager from Switzerland, delivered multiple sessions – from an introduction to ABB MineOptimize integrated electrification and automation, to deep-dives into grinding solutions (covering GMD, RMD and HPGR technologies) and gearless conveyor applications. Experts from ABB’s Finnish team – Tapio Apajalahti and Aki P. Selin – contributed insights on the latest developments in high-efficiency motors and drives, drawing on ABB Finland’s extensive experience in mining industries. Similarly, Erdem Mutafoglu (ABB Turkey) Javanshir Jafarov (ABB Azerbaijan) shared perspectives on their initiative to continue working in cooperation with ABB Kazakhstan team on low-voltage products.

Photo with ABB Switzerland representatives Image: ABB

Photo with ABB Azerbaijan representative. Изображение: ABB

Photo of presentation delivered by ABB Finland representative. Изображение: ABB

Natalija Gromova, General Director of ABB Kazakhstan, was present to commemorate the 30-year milestone and to reaffirm ABB’s commitment to its Kazakh customers. In her remarks (summarized by the event hosts), she emphasized the importance of continuous innovation and close partnership with local industry.

Overall, the anniversary seminar at the BeFine resort was more than a celebratory event—it marked a significant milestone in strengthening partnerships with representatives of Kazakhstan’s industrial sectors. By bringing together global expertise, showcasing cutting-edge technologies, and engaging local business leaders, ABB Kazakhstan demonstrated its commitment to working shoulder-to-shoulder with customers and partners.

The event reaffirmed ABB’s mission—not just to deliver equipment, but to build partnerships for progress, focused on boosting productivity and reducing environmental impact through smarter, cleaner solutions. As the mining industry evolves under the influence of digitalization and sustainability goals, ABB Kazakhstan—drawing on 30 years of experience—continues to be a trusted partner in the sector.

ABB is a global technology leader in electrification and automation, enabling a more sustainable and resource-efficient future. By connecting its engineering and digitalization expertise, ABB helps industries run at high performance, while becoming more efficient, productive and sustainable so they outperform. At ABB, we call this ‘Engineered to Outrun’. The company has over 140 years of history and more than 110,000 employees worldwide. ABB’s shares are listed on the SIX Swiss Exchange (ABBN) and Nasdaq Stockholm (ABB). www.abb.com

ABB’s Process Automation business automates, electrifies and digitalizes industrial operations that address a wide range of essential needs – from supplying energy, water and materials, to producing goods and transporting them to market. With its ~20,000 employees, leading technology and service expertise, ABB Process Automation helps process, hybrid and maritime industries outrun – leaner and cleaner. go.abb/processautomation