Holt Logistics Corp. is a single-source service provider to marine terminal operators, warehouses, and logistics companies. It is an independently managed affiliate of Greenwich Terminals LLC who operates Packer Avenue Marine Terminal in the Port of Philadelphia, which has direct access to distribution routes that span across the United States.

The Packer Avenue Marine Terminal, a premier container handling facility located on the Delaware River, has been described as one of the most productive terminals in the United States. The terminal has seven quay cranes and can handle ship capacities up to 16,000 TEU.

Transformation for growth

The Packer Avenue Marine Terminal has always been committed to leveraging technology to improve performance, safeguard its personnel, and ensure the seamless flow of cargo. Over the past decade, terminal technologies have advanced significantly, with computational analysis algorithms and generative AI now commonplace.

In recent years, gate operations became a clear constraint on the terminal’s growth potential. With manual processes that had reached their limits, the terminal was maxed out at around 1,200 gate moves per day. The need for more efficient solutions had become pressing if the terminal were to keep up with demand. Later on, the terminal also turned to crane OCR to further assist in faster throughput and increased growth.

Packer Avenue Marine Terminal has been able to meet growth targets over the years, partly due to its ability to choose the right partner to overcome specific challenges. For gate operations and crane OCR, it chose ABB – a decision that has helped improve the efficiency of container handling operations.

Automating the gate

Trucks and containers pass through multiple steps and controls as they enter and move through a container terminal, with their first point of call being the terminal gate. Trucks must be verified against work orders to gain admission, for example, and containers must be properly identified.

Previously, the process at the terminal involved the trucker leaving the cab to present paperwork, handle customs or other inspections, before receiving a printout to deliver to a terminal staff member at the drop-off slot. While less demanding, manual checks were also required when exiting the terminal. These paper-driven processes often placed terminal staff out in the open and in close proximity to trucks and container handling equipment.

With the implementation of the gate OCR system, we see a significant reduction of transaction times, from 10 minutes to as little as two minutes and 30 seconds.

Today, OCR portals with line scan cameras at the gates allow the Packer Avenue Marine Terminal to capture high-resolution still images of trucks and containers entering the facility and process the information without face-to-face interaction. The system instantly checks data against the database to verify incoming cargo. Camera software also records additional container information such as hazardous materials, bolt seal, and more. With automatic data processing, staff can focus on handling exceptions, which are managed from a central control room.

“With the implementation of the gate OCR system, we see a significant reduction of transaction times, from 10 minutes to as little as two minutes and 30 seconds,” says John Burleson, General Manager of Greenwich Terminals, the operator of Packer Avenue Marine Terminal.

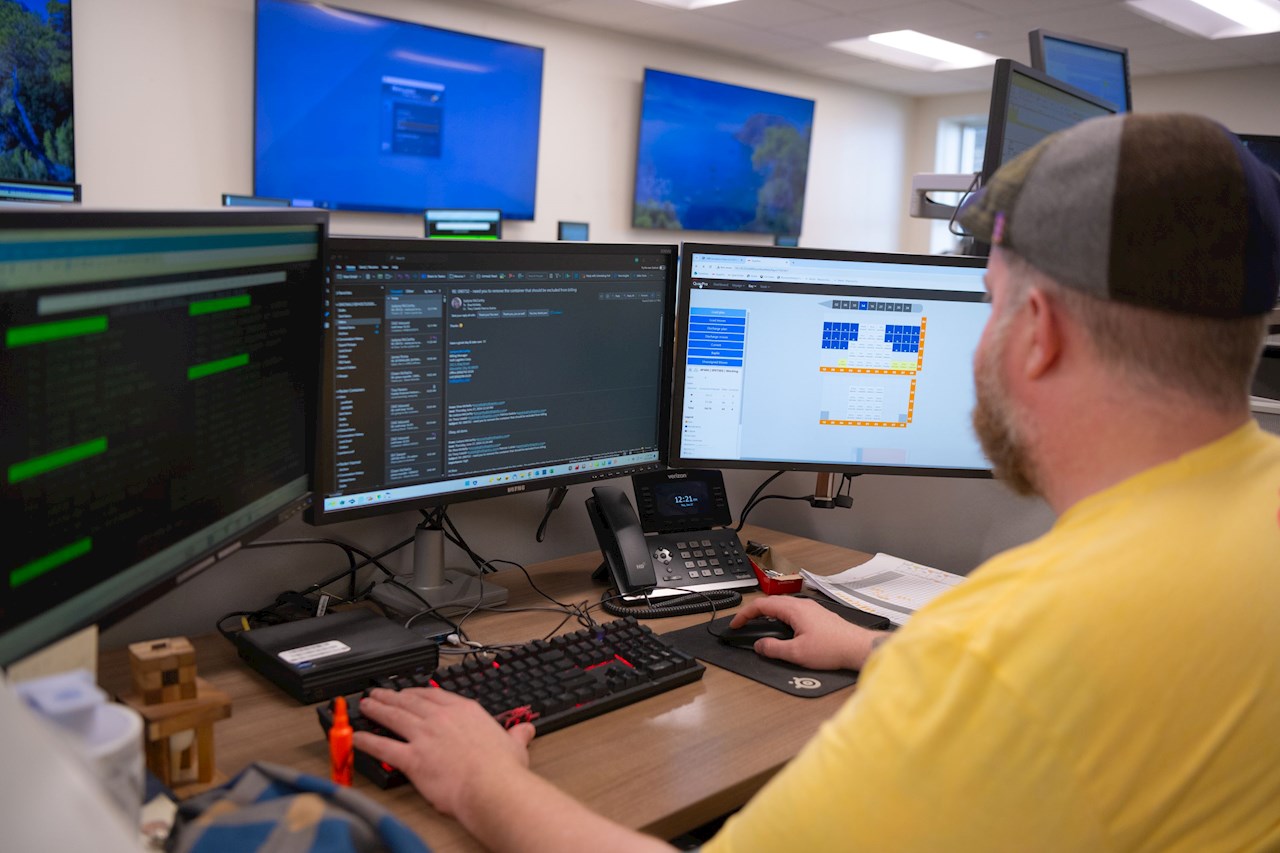

In fact, the transition to more automated operations has been well received by employees. They have been moved away from working on foot with trucks to an office location, which is a tremendous improvement from a safety perspective. In addition, they now work in a comfortable environment protected from heat, extreme cold, rain, wind, and snow. With this improved working environment comes increased productivity.

The implementation of new technology was never about eliminating jobs, stresses Burleson. “We moved labor to more critical areas to enhance operational fluidity and improve the working environment. We continue to develop other areas of the operation to increase labor hours, grow the business for the region, and benefit our partners. This has been a team effort for us,” he says.

The ability to move clerks between different operational areas, thanks to the unified system, has further enhanced flexibility and efficiency. “Employees working together as a team, collaborating, looking over each other’s shoulders to ask questions, helping one another, and transitioning between tasks instantaneously – this has been tremendous for our growth and productivity,” says Burleson.

“Employees working together as a team, collaborating, looking over each other’s shoulders to ask questions, helping one another, and transitioning between tasks instantaneously – this has been tremendous for our growth and productivity” John Burleson, General Manager, Greenwich Terminals Image credit - ABB

With automatic data processing, staff can focus on handling exceptions, which are managed from a central control room. Image credit - ABB

Proceeding to crane OCR

The safety and efficiency gains naturally led Packer Avenue Marine Terminal to consider additional applications, with crane OCR offering an end-to-end solution that supports faster throughput and continued growth.

Crane OCR allows us to give real-time updates to our terminal operating system and to our customers on container availability and location in the facility.

The quay crane cameras in ABB’s Crane OCR solution identify containers during load and discharge operations, while the MatchMaker module matches each container with the correct terminal truck, enabling complete tracking of the container through the facility, from discharge to its final storage location in the yard.

“This allows us to give real-time updates to our terminal operating system and to our customers on container availability and location in the facility,” says Burleson.

Crane OCR offers an end-to-end solution that supports faster throughput and continued growth, identifying containers during load and discharge operations. Image credit - ABB

QuayPro, which remotely tracks and verifies container stowage plans in real-time, provides immediate insights and a virtual stow of the vessel during both discharge and loading, while alerting clerks in the office to any inconsistencies. Image credit - ABB

Digitalizing quay operations with QuayPro

Another module used by the terminal is QuayPro, which remotely tracks and verifies container stowage plans in real-time. It provides immediate insights and a virtual stow of the vessel during both discharge and loading, while alerting clerks in the office to any inconsistencies.

“The system picks up any container errors so we can react in real-time and correct them. This allows us to generate BAPLIES almost instantaneously based on the collected data and present it to the ship so it can be dispatched and sail faster,” Burleson continues.

The QuayPro module also includes a playback tool, allowing the terminal to go back and review the vessel operations and crane movements, to support continuous improvement.

The QuayPro module picks up any container errors so we can react in real-time and correct them. This allows us to generate BAPLIES almost instantaneously based on the collected data and present it to the ship so it can be dispatched and sail faster.

Alan Dow, Assistant General Manager, Greenwich Terminals, is unequivocal about the role of ABB technology in enhancing terminal efficiency. “ABB has helped us grow immensely over the years,” he says. “ABB Crane solutions help us be more accurate in what’s loaded and discharged on every vessel. Together with the gate automation solutions, it has made us more reliable overall. Going from manual mode to semi-automatic mode has been game-changing. There is no way we could be where we are today without these solutions.”

Burleson also describes the relationship between Greenwich Terminal and ABB as transformative. “By leveraging strategic partnerships and innovative solutions, Packer Avenue Marine Terminal has successfully navigated the complexities of modern logistics and is now poised for significant growth,” he says.

“As our proven partner, ABB has helped us to grow into something we never envisioned or imagined would be possible. We thought we were pretty much maxed out at 1,200 gate moves a day going through the facility. Now we are an 800,000 TEU facility on a small footprint. We appreciate how far we have come and are excited about where we are headed in the future.”