Founded in 2018 in Genoa, Hiro Robotics is an Italian company specializing in turnkey solutions for the automated disassembly of disused electronic devices. Serving waste treatment operators as well as electronics producers and distributors, the company already has projects operating in several recycling plants. In collaboration with ABB Robotics, Hiro Robotics is developing advanced circular economy robotic solutions that automate the recovery of valuable electronic components for reuse in the manufacture of new products.

A huge opportunity

The world faces a growing mountain of electrical and electronic waste. Some 62 million tons were produced in 2024, of which 78% was not treated in compliance with regulations, according to the United Nations’ Global Waste Monitor. This represents an estimated cost of €78 billion to people and the environment, yet it also presents a huge opportunity: Harvesting the valuable materials locked away in this waste stream could generate an estimated €82 billion in reusable resources.

The disassembly of electronic waste presents numerous challenges. Issues with complexity and poor ergonomics mean that traditional processes are slow and inefficient. Moreover, the use of methods such as indiscriminate shredding can lead to contamination of materials and the release of pollutants like mercury, reducing the amount of recoverable material, and impacting sustainability.

To overcome these challenges, HirO Robotics is developing ‘de-manufacturing’ solutions that apply advanced technologies such as robots, artificial intelligence and machine vision to help automate the sustainable disassembly of electronic waste.

Complete flexibility

Any disassembly solution needs to be extremely flexible. While traditional production processes churn out millions of identical items, recycling centers need to be able to dismantle electronic devices of any model, size, and material, many of which are also likely to be broken or dirty.

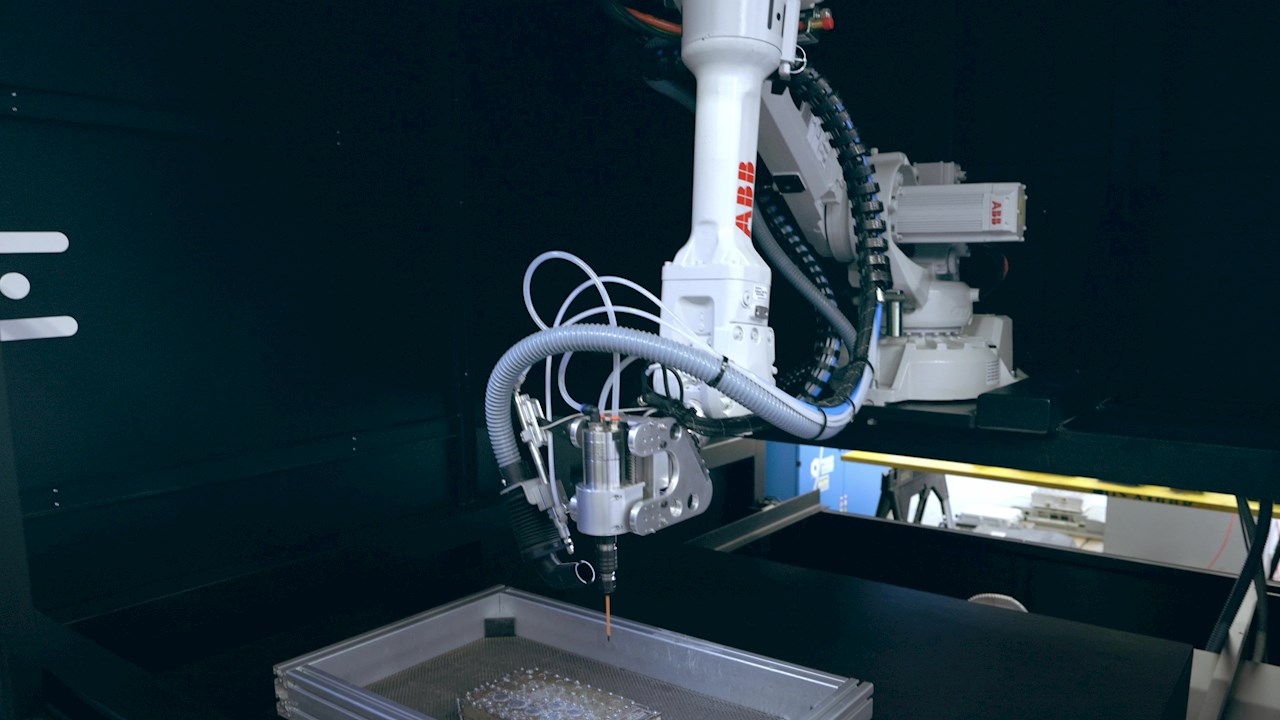

Hiro Robotics’ disassembly system for flat-screen TVs and monitors uses three robotic stations: the first to unscrew the back case, the second to break the front bezel, and the third to unscrew the internal components. Human operators can then complete the final material sorting. This modular approach can be adapted to process up to 90 monitors per hour, significantly reducing processing time, improving efficiency, and reducing operating costs.

One of these projects is the TEIA recycling plant located at the Bollate Correctional Facility near Milan. A collaboration between the City of Milan and local waste management companies, the LaboRAEE project is a novel initiative that combines social benefits with sustainability improvements by providing inmates with an opportunity to carry out paid work and acquire real marketable skills. At the 3,000 m² facility, inmates receive hands-on training to dismantle, and sort discarded electronic equipment. Working alongside them is HiRO’s automated system, which uses based on ABB IRB 2600 and IRB 460 robots to carry out repetitive tasks including separating and sorting components. The robots are also used for handling heavy or potentially hazardous materials, improving efficiency while ensuring higher safety standards.

By combining human expertise with robotic innovation, the project represents an effective circular-economy model that reduces waste, supports rehabilitation, and provides a benchmark for sustainable e-waste management.

Other innovative projects

While the company’s systems to process TVs and monitors were the first to be deployed, Hiro Robotics already has a range of other electrical goods in its sights, such as servers and data center equipment, telecommunications equipment, inverters, and hard drives. As the technologies designed to promote sustainability continue to mature, Hiro Robotics is also turning to automation to take on jobs such as the delamination and frame removal of photovoltaic panels and the detection of flammable batteries in mixed waste streams.

Future ambitions

Hiro Robotics hopes its vision will help shape the future of recycling in Europe over the next few years, thanks in part to its work with ABB as a leading advocate of intelligent robotic automation. With the United Nations predicting a 32 percent increase in the generation of global e-waste to 82 million tonnes by 2030, the turnkey recycling solutions being developed by the partners will be truly transformative.