A major shift in electric motor standards is coming, and consulting and specifying engineers are positioned to lead the transition. On June 1, 2027, the U.S. Department of Energy (DOE) will require higher efficiency levels for a wide range of industrial motors. It will be the most significant update in more than a decade. The timing is critical. Projects designed in 2025 and 2026 may not break ground until after the rule takes effect. Engineers who plan ahead can help avoid redesign costs, lower long-term operating expenses and show how today’s design choices strengthen sustainability and competitiveness.

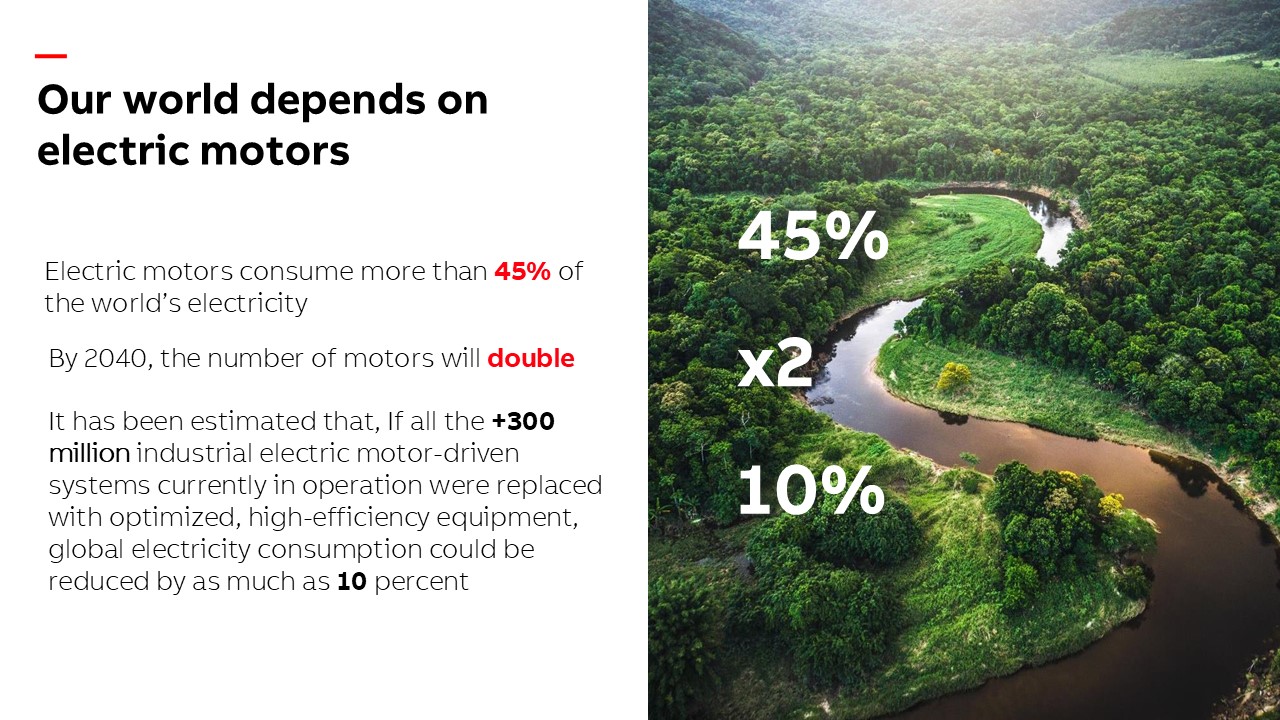

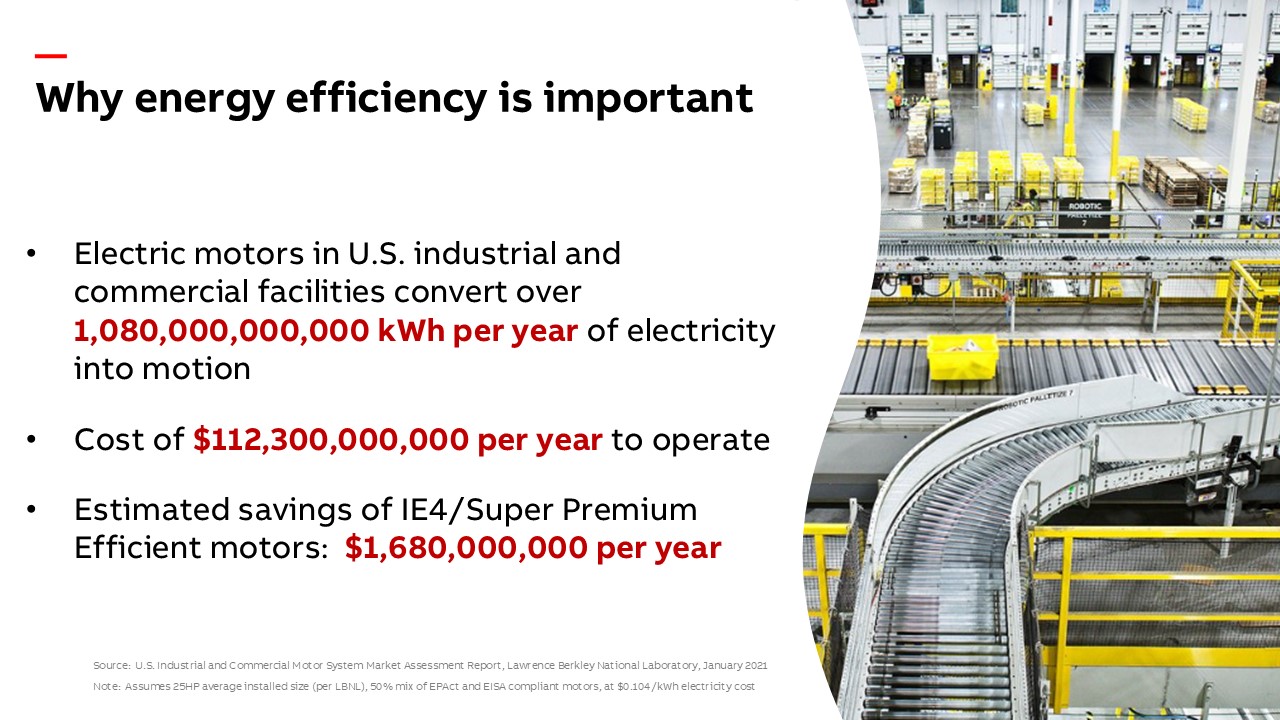

Electric motors are the backbone of industrial productivity, powering pumps, compressors, conveyors and HVACR systems. They consume more electricity than any other industrial technology. Globally, motors account for more than 40% of power use, and in the United States they draw more than a trillion kilowatt-hours each year, costing $112 billion. Even modest efficiency gains across fleets of motors can reshape the economics of entire industries. The new DOE standards reflect that reality. For engineers, they are more than a compliance exercise. They are an opportunity to guide smarter designs, lower costs and deliver measurable sustainability progress.

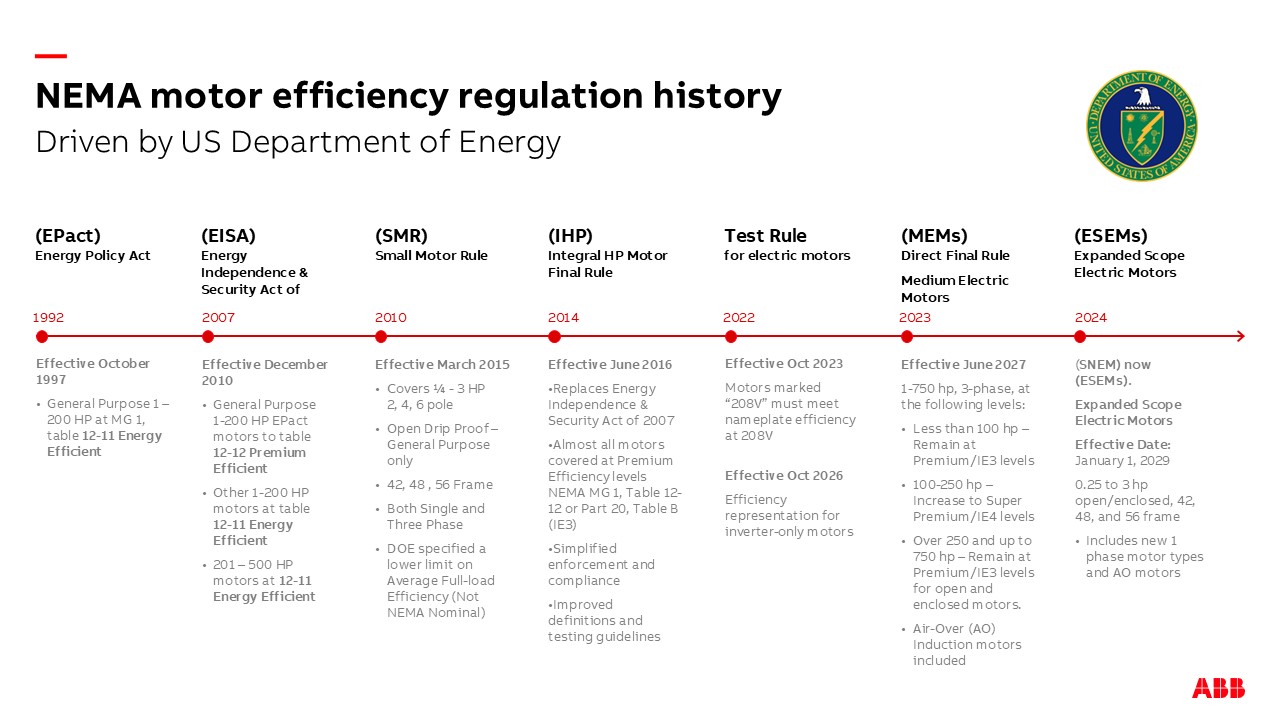

A History of Rising Standards

The 2027 rule is not a sudden change. It is the latest step in U.S. policy steadily raising the floor for motor performance. The Energy Policy Act (EPAct) of 1992 created the first federal baseline for general-purpose motors, requiring efficiency in every design and procurement decision. Fifteen years later, the Energy Independence and Security Act (EISA) of 2007 expanded coverage and set minimums that aligned with what is now NEMA Premium, or IE3 efficiency. By then, the market had matured and technology had improved enough that regulators could expect more. The following decade brought additional DOE rules that broadened scope: the Small Motor Rule, the Integral Horsepower Rule and the Medium Electric Motor Rule. Each followed the same pattern. As manufacturers advanced and costs fell, regulators raised expectations.

Global Trends in Electrification

Global trends reinforce the urgency of these standards. The International Energy Agency (IEA) reports that industry uses 37% of global energy, with motors consuming about 70% of that total. As urbanization and automation accelerate, demand for motor-driven systems is expected to double by 2040. High-efficiency motors, especially those meeting IE4 and IE5 benchmarks, provide a critical pathway to sustainable growth. For engineers, this context matters. Every major project in the last 30 years has been shaped by rising standards, and the 2027 rule is another step forward. By moving this core band of industrial motors to IE4, DOE is targeting the most common equipment where the largest savings can be achieved.

The 2027 Regulatory Shift

The DOE’s direct final rule, published in 2023, covers three-phase induction motors from 1 to 750 horsepower. Beginning June 1, 2027, mid-range motors must meet IE4 efficiency, while smaller and larger motors will continue to meet IE3. On January 1, 2029, coverage expands to fractional horsepower motors from one-quarter to 3 horsepower in frame sizes 42, 48 and 56. The rule applies to single-speed, continuous-duty motors with squirrel-cage rotors, operating on polyphase 60 Hz sinusoidal line power at 600 volts or less, and built in standard NEMA or IEC frame sizes. Covered motors must meet the requirements of NEMA Design A, B, BE, C or CE, or IEC Design N, NE, NEY, NY, H, HE, HEY or HY. Exemptions include liquid-cooled, submersible, synchronous, inverter-only motors and component sets, though any efficiency claims for these must still be certified under DOE procedures. DOE is phasing in enforcement. Between October 2023 and October 2026, testing and labeling requirements are in effect. On June 1, 2027, compliance becomes mandatory for covered motors, followed by the expanded fractional horsepower coverage on January 1, 2029.

Measuring Efficiency and Projected Impact

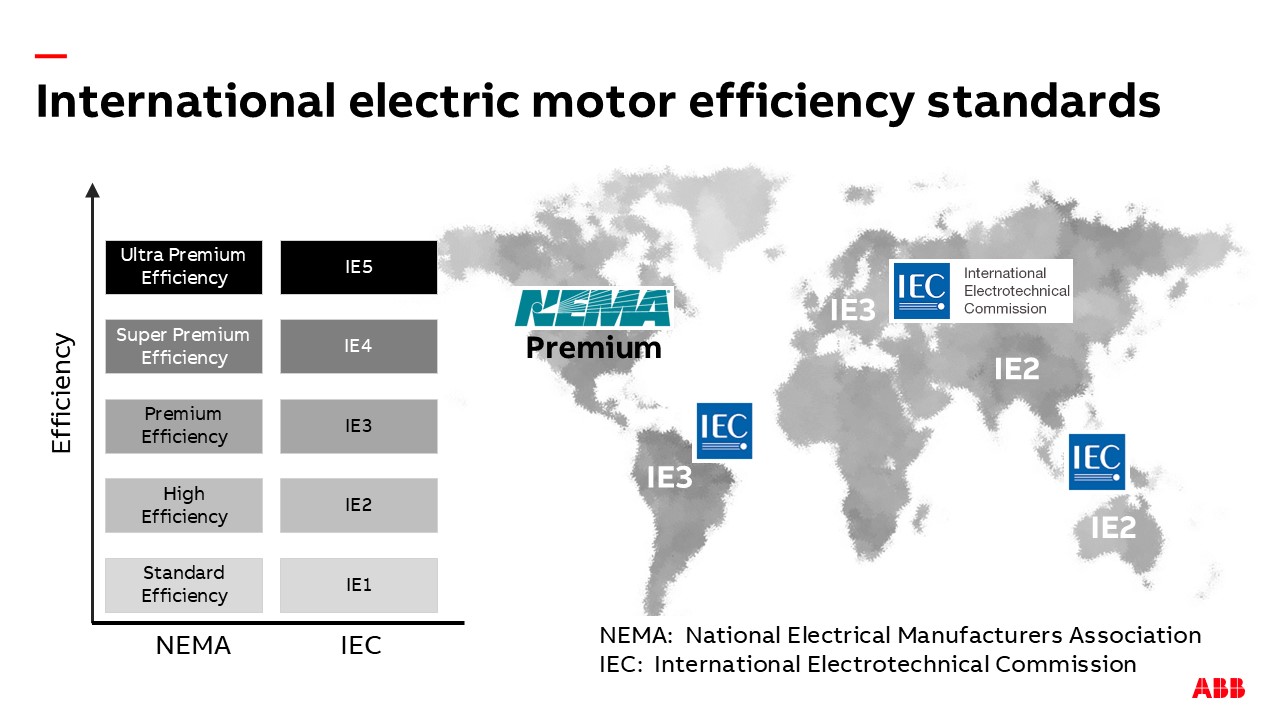

Motor efficiency is the ratio of mechanical output power to electrical input power. To ensure consistent comparisons, efficiency levels are classified by international and U.S. standards:

- IE1: Standard efficiency

- IE2: High efficiency

- IE3: Premium efficiency, the U.S. baseline since 2007

- IE4: Super-Premium efficiency, soon required for mid-range motors

- IE5: Ultra-Premium efficiency, recognized internationally but not yet adopted by NEMA

Each step delivers measurable gains. A 200-horsepower motor must reach 96.2% efficiency to qualify as IE4. That number may appear small, but over decades of operation it translates into hundreds of thousands of dollars in energy savings. In the United States, efficiency ratings are governed by NEMA MG 1 tables, which form the basis of DOE compliance. These tables define nominal full-load efficiencies across motor types and configurations, ensuring performance is verifiable and consistent. The stakes are significant. DOE projects the 2027 rule will save businesses $8.8 billion and prevent 92 million metric tons of CO₂ emissions over 30 years. For engineers, the motors specified today will directly affect operating costs and sustainability performance for decades to come.

DOE Testing and Certification

The DOE requires motors to be tested under procedures in 10 CFR Part 431 Subpart B. These include measuring full-load efficiency under standardized conditions, certifying efficiency claims through third-party validation or approved Alternative Efficiency Determination Methods (AEDMs), and labeling with nominal efficiency and a compliance certification number (CC#). Manufacturers must register motor models with the DOE and back all claims on nameplates, catalogs and marketing materials with certified test data. Importers share this responsibility and face penalties for violations. For end users, these procedures ensure motors perform at the efficiency levels shown on their nameplates. Engineers can compare existing equipment with newer technologies and use tools such as DOE calculators, utility programs or ABB’s Energy Savings Calculator to estimate payback and lifetime savings.

What It Means for Stakeholders and Engineers

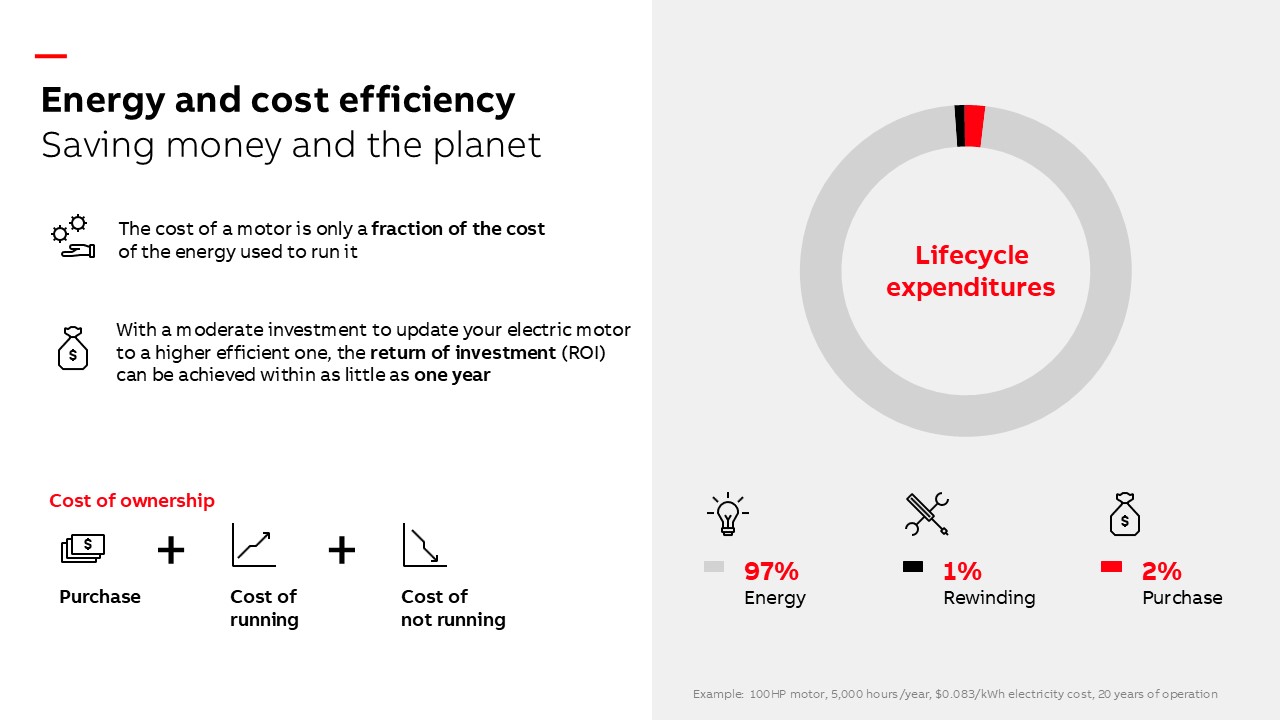

The 2027 standards will ripple across the supply chain. Manufacturers must redesign key models with higher-grade materials, refined methods and added testing. While costs may rise, early investment creates opportunities for innovation and market leadership. Distributors will need to replace noncompliant inventory and update catalogs, with sales teams explaining new specifications and price points. Operators and end users carry the greatest long-term costs. A typical motor may cost about $7,000 to buy but more than $600,000 to power over its life. Boosting efficiency by 10 to 15% can cut operating expenses significantly, often with payback in one to three years.

For engineers, the rule expands their role beyond compliance. They can reframe decisions around lifecycle cost, showing that energy expenses far exceed purchase price. They can link motor upgrades to corporate sustainability and ESG goals, since high-efficiency motors cut consumption and emissions and provide verifiable data for reporting. Replacing existing fleets with IE4 models alone could reduce global electricity use by as much as 10%.

Efficiency also strengthens reliability. IE4 motors run cooler and with less loss, extending service life and enabling predictive maintenance when paired with drives and monitoring systems. Incentives add another lever. More than 160 utility programs across the U.S. offer rebates for motors that meet or exceed DOE standards, helping shorten payback periods and move projects forward.

Case Studies and Industry Impacts

The 2027 standards will affect every industry, though the impact varies by sector. For engineers, tailoring these examples to operational priorities is one of the most effective ways to demonstrate value.

Food and beverage facilities in the U.S. consume more than 24 billion kWh annually at a cost of $2.4 billion. Upgrading to IE4 motors could save more than $36 million each year, especially in continuously running applications like mixers, pumps and conveyors.

Metals and mining operations rely on large motors powering crushers, mills and ventilation systems under extreme loads. Replacing standard induction motors with IE4 models can cut energy losses by up to 40% while also improving durability.

In HVACR and water treatment, fans, compressors and pumps are among the most energy-intensive components in the built environment. Pairing IE4 efficiency with variable speed drives yields energy savings and more precise system control.

Commercial buildings such as hospitals, universities and office towers face pressure to meet sustainability benchmarks and manage budgets. Specifying IE4 motors helps reduce operating costs, support compliance with programs like LEED and strengthen market reputation.

ROI in Action

Consider a motor operating 5,000 hours per year at an electricity cost of $0.083/kWh. Over 20 years, the energy cost totals $620,000, while the motor itself costs around $7,000. Upgrading to an IE4 motor can reduce energy consumption by 10 to 15%, yielding ROI in less than three years, especially when paired with utility rebates. Online calculators and energy modeling tools make it easy for engineers to demonstrate this. By showing payback alongside compliance, engineers can shift efficiency from a regulatory burden to a financial opportunity.

Global Context

The 2027 DOE standards are part of a global movement toward higher efficiency. In the United States, IE3 is the baseline, with IE4 required for mid-range motors in 2027 and expanded fractional coverage in 2029. The European Union has required IE3 since 2021 for motors from 1 to 1,000 kW, with IE4 mandatory since 2023 for 75 to 200 kW. Canada typically aligns with U.S. rules and is expected to adopt similar standards by 2027, while Asia-Pacific countries such as China and India are also introducing higher requirements, though enforcement varies.

The IEC and NEMA efficiency classes are broadly aligned but not identical: IE3 aligns with NEMA Premium, IE4 with NEMA Super Premium, while IE5 has no formal NEMA equivalent. For engineers working on international projects, designing to the highest available standard is often the safest approach.

Organizations such as IEA and ISO are pushing for harmonization of standards to simplify compliance and accelerate adoption of high-efficiency technologies, multiplying savings worldwide. Companies importing motors into the United States must meet DOE certification and labeling requirements, while U.S. manufacturers exporting to the EU must comply with IEC efficiency levels and CE marking. This underscores the importance of designing motors that meet or exceed the highest standards, enabling companies to compete globally while advancing sustainability goals.

Industry Leadership and Strategic Collaboration

While DOE sets regulatory baselines, industry leaders play a critical role in shaping and supporting implementation. ABB, for example, has been active in regulatory discussions and technical committees that influence motor efficiency standards. Beyond compliance, the company founded the Energy Efficiency Movement, a global initiative uniting businesses, partners and policymakers to accelerate industrial efficiency. Through this work, ABB provides research, tools and shared knowledge that strengthen the industry’s ability to meet rising expectations. The company also develops advanced designs optimized for energy savings and sustainability. These motors deliver high performance with reduced losses, supporting both compliance and operational excellence.

To ease the transition, ABB offers services such as efficiency audits and retrofit assessments, guidance on AEDM validation and DOE registration, integration with variable speed drives and lifecycle programs that promote circularity. These efforts make efficiency practical, not just theoretical. For engineers, they represent resources and partnerships that can quantify savings, reduce risk and strengthen the case for high-efficiency motors.

Incentives and Rebates

The upfront cost of upgrading to IE4 is real, but financial support exists. According to the Database of State Incentives for Renewables & Efficiency (DSIRE), more than 160 U.S. utilities offer rebates for motors that meet or exceed DOE standards. Programs can be searched by ZIP code and equipment type, helping engineers identify opportunities to offset capital costs. By incorporating incentives into proposals, engineers can shorten payback timelines and present stronger business cases. A motor that might otherwise take three years to pay off may do so in two. That difference often moves projects from “someday” to “now.”

A Roadmap for Engineers

The standards present engineers with a practical question: how to prepare now for projects that will operate after 2027.

- Specify IE4 now. Making IE4 the baseline in specifications avoids redesign costs and ensures long-term compliance.

- Educate stakeholders. Demonstrating how lifecycle energy costs outweigh upfront prices helps shift decision-making.

- Leverage incentives. Rebates and utility programs can accelerate ROI and move projects forward.

- Integrate with drives and monitoring. IE4 motors deliver maximum value when paired with systems that enhance performance and reliability.

- Document outcomes. Providing projected savings, carbon reductions and payback periods strengthens both sustainability reporting and financial planning.

The 2027 DOE standards are more than a compliance requirement. They mark a turning point in how industry consumes energy and how engineers shape that future. By specifying IE4 motors today, consulting and specifying engineers can reduce risk, cut operating costs and support measurable sustainability goals. More than that, they can lead the conversation about efficiency, resilience and competitiveness. The rule is set. The opportunity lies in how engineers choose to respond.