The challenge

Leading instant milk and bubble tea brand, Xiang Piao Piao, was looking to improve production efficiency and stability, achieve fast and intelligent production changeovers, and reduce production costs in its manufacturing.

The solution

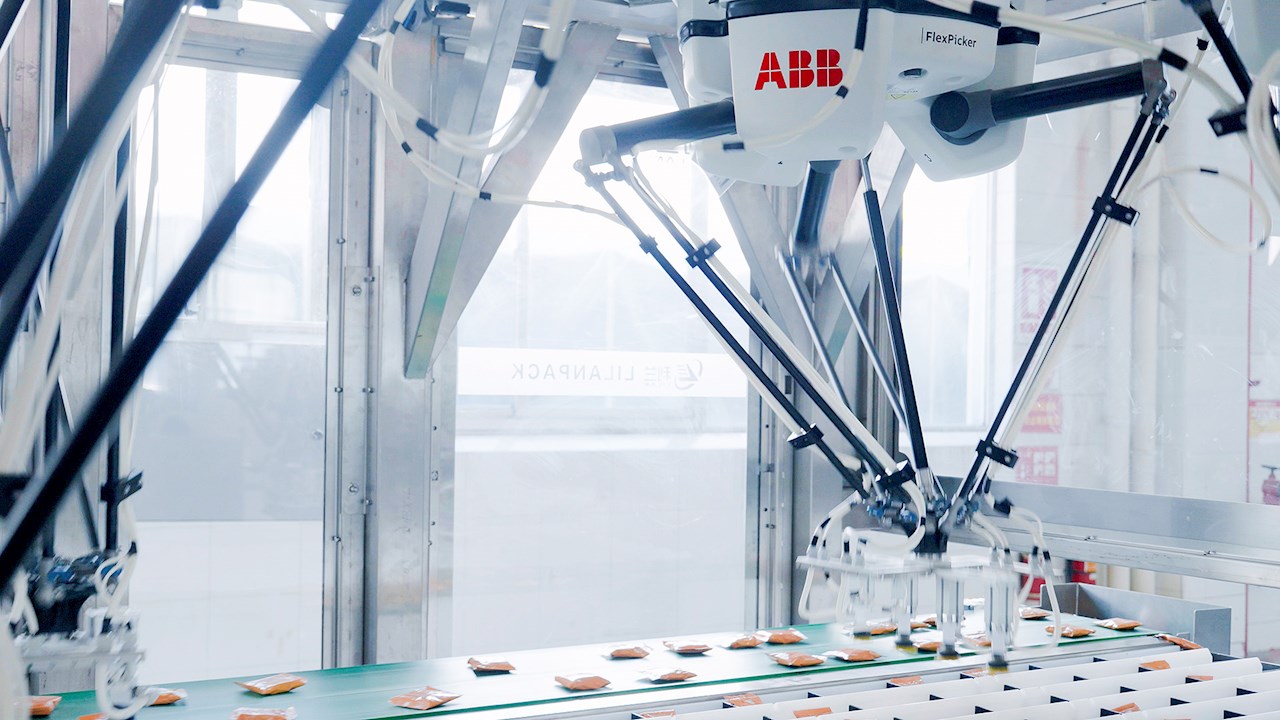

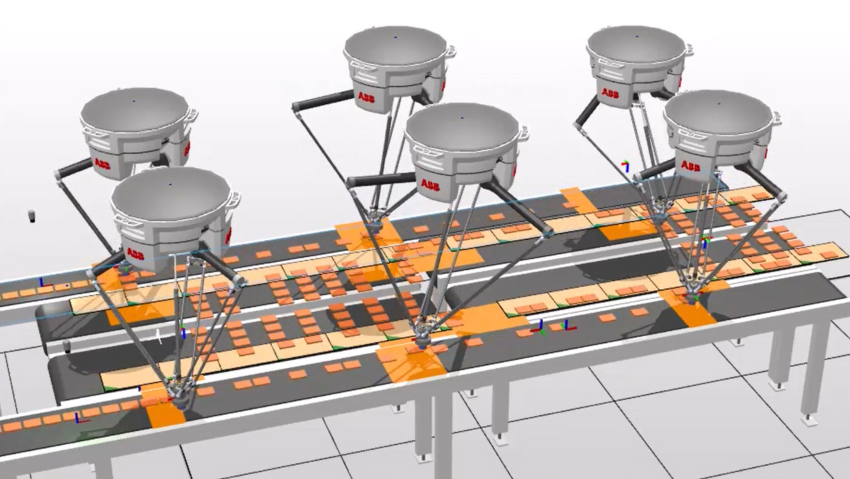

One hundred ABB FlexPicker IRB 360 robots are used across the company’s three production sites to enable high-speed production, with the lines now capable of handling 500 products per minute (ppm).

The application

The FlexPicker IRB 360 robots and PickMaster® Twin are helping to ensure fast and precise picking and placing of milk tea ingredients, improving production efficiency by 40 percent.

Founded in in 2005, Xiang Piao Piao is a pioneer in instant milk tea and bubble tea drinks, with 1.4 billion customers in China and worldwide consuming its products.

To help it accommodate growing demand, the company wanted a flexible high-speed production line that could handle increased throughout and adapt quickly and easily to different products and ingredients.

“The robots needed to accurately identify and distribute ingredients and raw materials to the appropriate production line, and fast,” explained Zhu Fei, Factory director at Xiang Piao Piao’s Huzhou facility.

The robotic equipment needed to be easy to maintain to help reduce operating costs, as well as meet food-grade safety standards to ensure hygiene and a high product quality. Space constraints also posed an additional challenge, with the robots needing to fit in a confined area.

Increasing production efficiency by 40 percent

A total of one hundred FlexPicker robots have been deployed across Xiang Piao Piao’s Huzhou, Chengdu and Tianjin factories. The robots are primarily used for two tasks, intelligently picking and placing sugar packets and handling packaging operations such as splitting and sorting product and red bean packages; and picking and placing coconut cups, a key ingredient in one of the drink ranges.

Since installing the robots, Xiang Piao Piao has greatly improved production efficiency. Picking speed has increased by 15 percent, and the overall efficiency of the line has increased by 40 percent, maximizing output. At the Huzhou factory, all ingredients are handled by six ABB robot automatic delivery lines, saving Xiang Piao Piao over two million yuan a year.

An advanced automation system

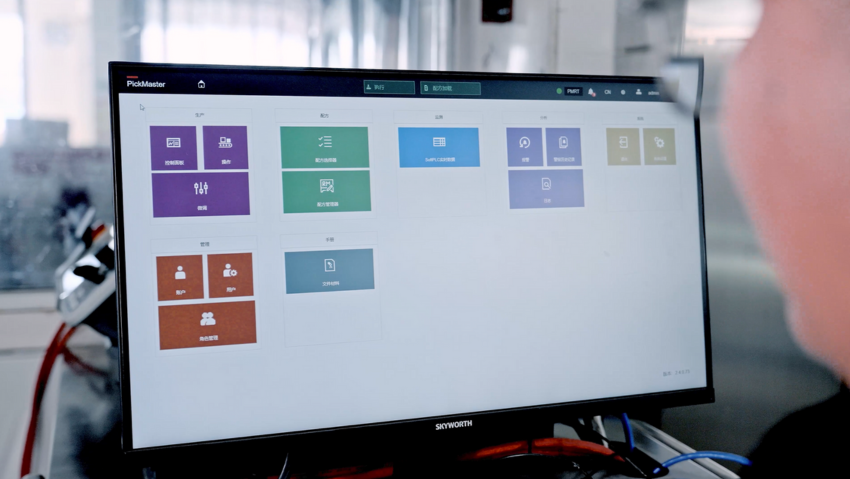

Using ABB’s PickMaster® Twin digital twin software to create and test virtual production lines and configurations has dramatically reduced disruption by shortening commissioning times and enabling product changeovers to be easily carried out in minutes.

“We have been delighted with the performance of the system and the efficiency gains,” said Fei. “A particular advantage of the PickMaster® Twin is its digital production dashboards and intuitive interfaces, which makes data easy to visualize.”

The system also offers additional benefits. By automating the repetitive and monotonous tasks with robots, workers have been able to focus on higher-value activities. Using the robots has also helped minimize human error and lowered the risk of product contamination.

Truly flexible performance

“The FlexPicker IRB360 and PickMaster® Twin solution has been invaluable to us,” said Fei. “The use of AI technology in the vision system means that the robots can easily and accurately recognise differences in packet shape and size, as well as the various dynamic positions of the packets, so we have been able to improve production efficiencies significantly.”

“We are so pleased with the successful outcome of this project that we are planning three more projects to introduce more robotics across our factories.”