Global energy demand is soaring. The IEA’s World Energy Outlook 2025 shows that total demand grew by more than 2% in 2024 to over 650 exajoules – well above the long‑term average. Explosive growth in data centers and AI, air conditioning, and the rapid electrification of transport are all pushing electricity use through the roof.

As the “first fuel” of the energy transition, energy efficiency is a crucial piece of the puzzle. It’s the fastest, most cost‑effective way to meet rising demand, and do so sustainably.

It’s also a key premise on which ABB has built its “Engineered to Outrun” philosophy. We develop technologies that don’t just cope with change but outperform it, alleviating the pressure of growth and limited resources.

Our new LV Titanium Variable Speed Motor (VSM) platform is a prime example: a streamlined, speed‑controlled motor solution designed to avoid emissions at source and make high‑efficiency operation the easy choice, even for facilities with limited space and internal expertise.

Compact design for greater efficiency

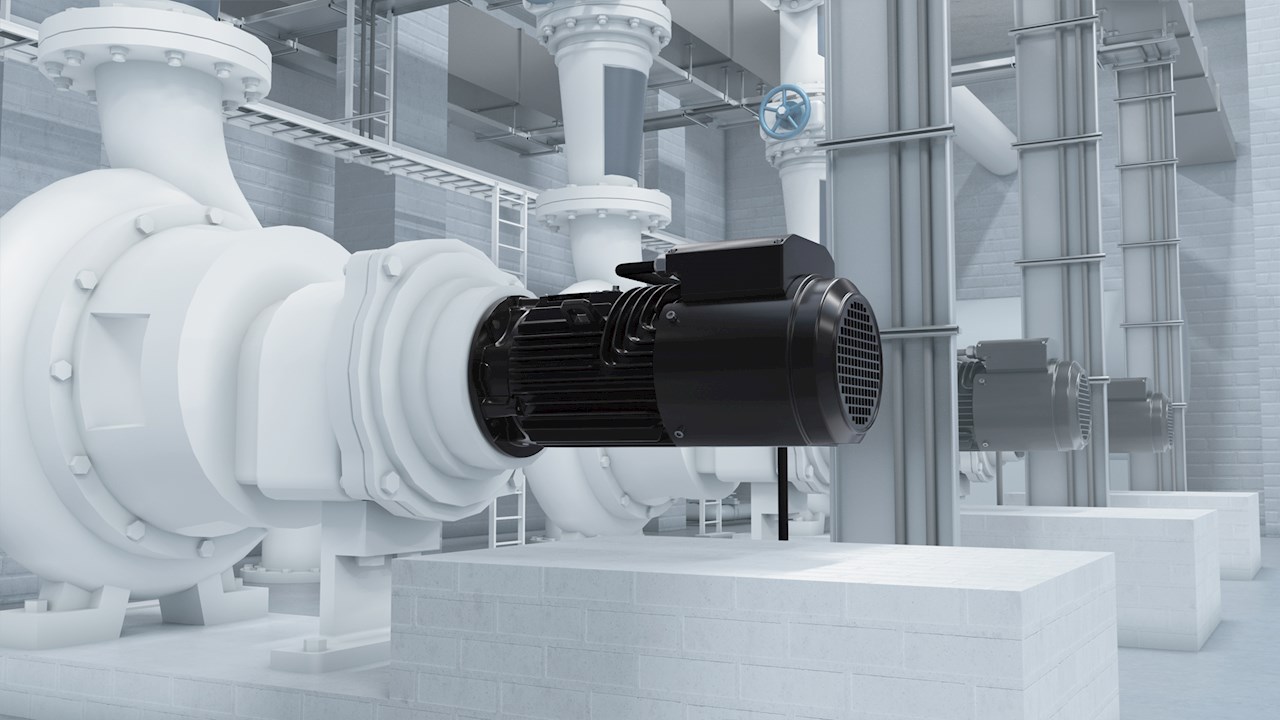

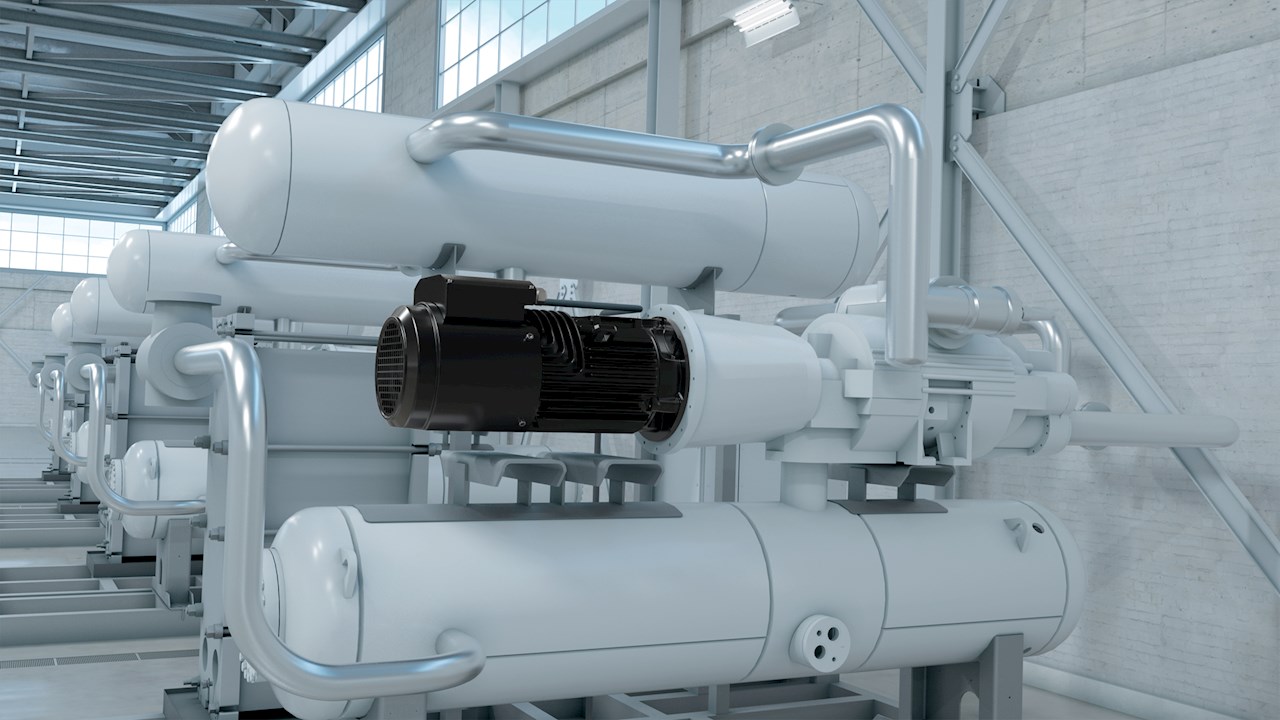

The LV Titanium platform offers a completely new way to introduce energy efficiency on the factory floor. Instead of specifying a separate motor and variable speed drive (VSD), then wiring and configuring them on site, LV Titanium combines both into a single, compact unit.

A purpose‑designed drive module is mounted axially at the end of an IE5 Ultra‑Premium efficiency permanent magnet (PM) motor. The two-in-one unit is well suited for pumps, fans, compressors, and other industrial applications across multiple power and speed ranges.

This all-in-one design is a direct route to energy savings. Around the world, millions of fixed‑speed motors still run at full power even when demand is low. Simply matching motor speed to process needs using a drive can typically reduce electricity consumption by around 25%, yet less than a quarter of industrial motors are equipped with one.

By combining high-efficiency motor design with variable‑speed control in one compact platform, LV Titanium helps turn energy efficiency ambition into real‑world reductions, helping industry cut energy use at source.

Substantial cuts in energy spend

The impact on energy cost and carbon footprint can be significant. Over a motor’s lifetime, around 97% of its Total Cost of Ownership (TCO) comes from the energy it uses, which means efficiency has the greatest influence. In continuous‑duty applications such as pumps, fans, and compressors, LV Titanium’s IE5 Ultra‑Premium efficiency and speed control can deliver immediate savings.

In a typical 15 kW centrifugal‑pump application, replacing an IE3 direct‑on‑line motor with an LV Titanium can save around €8,122 in electricity costs each year. For a motor operating 6,000 hours annually, that adds up to roughly €121,830 over 15 years.

The benefits go even further. An LV Titanium upgrade can avoid about 11,600 kg of CO₂ emissions per year – or 174,000 kg over 15 years – which equals the annual emissions of 40 gasoline‑powered passenger cars. And this is the result from just one motor. In facilities such as water treatment plants, food and beverage factories, or large data centers – where dozens, hundreds, or even thousands of similar motors are in service – the potential savings make a world of difference.

Reduced complexity

We developed the LV Titanium in close collaboration with customers who needed a practical, straightforward way to modernize existing equipment. Many industrial plants operate legacy systems with long‑life assets and are understandably cautious about retrofits that might disrupt production or require extensive redesign.

The Energy Efficiency Movement’s 2025 “Efficiency Now” report backs this up, with 19% of industrial respondents citing infrastructure limitations and the risk of downtime as key barriers to adopting energy efficiency solutions.

The LV Titanium addresses these concerns head‑on. It comes as a plug‑and‑play unit, factory‑commissioned and ready to integrate into existing infrastructure without the need for external drive cabinets or complex rewiring. It is configurable to suit a wide range of installation requirements, making it equally suitable for new systems and upgrade projects.

With less complexity and faster installation, this breakthrough design helps turn industry’s low‑carbon ambitions into reality. Ease of adoption is critical, especially in plants with limited internal specialist skills and maintenance resources. Here, too, LV Titanium is designed to remove obstacles. Its compact, high‑power‑density design means it can be up to three frame sizes smaller than a comparable induction motor. In cramped production lines, it’s a game changer.

LV Titanium Variable Speed Motor ideal for applications like both vertical and horizontal

LV Titanium Variable Speed Motor for compressor applications

LV Titanium Variable Speed Motor for fan applications

LV Titanium Variable Speed Motor for pump applications

Efficiency now for future sustainability

ABB’s LV Titanium VSM platform gives industrial operators a powerful, future‑ready tool to reduce emissions and stay competitive. The technology is designed to solve today’s challenges and keep delivering efficiency and sustainability gains for years to come.

Want to find out more about how LV Titanium can cut your energy costs and guide your path to lower emissions? Our expert teams can show you where to start, what to upgrade, and how quickly you can save. Get in touch today, start your energy efficiency journey tomorrow.