In the 1980s, Kurt Danielsson changed the fly-fishing reel forever. He was not satisfied with the reels available on the market, so he developed Danielsson Flyreels himself. The design he created is now of a global standard. Today, his son Tomas continues the innovative legacy. He has developed Raptor, an efficient and environmentally friendly machine that handles the large amounts of hard-to-process aluminum shavings created during reel production. Tomas contacted ABB already at the concept stage.

“Building a completely new and unique machine comes with many challenges. That’s why it’s important to trust that the components will work. ABB has always been available, which is crucial during development when you need fast answers from people with product expertise”, says Tomas Danielsson.

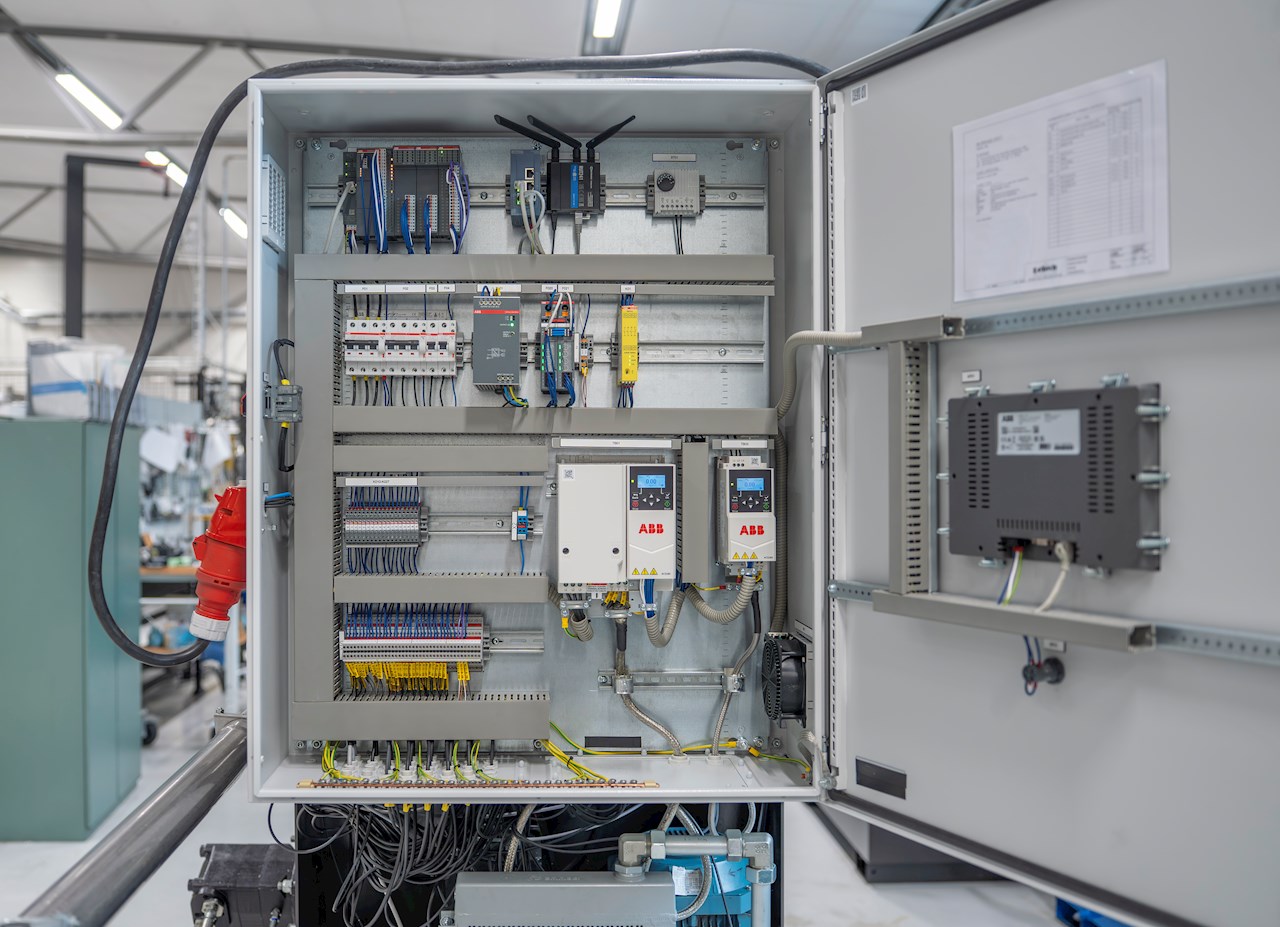

Raptor’s innovative solution for automated metal shavings handling is based on Tomas Danielsson’s own patented system with dual shredders and supporting equipment, combined with proven ABB technology. This includes motors, PLCs, drives, and low-voltage products. Together, these components form an integrated system that drives, controls, and secures the machine’s functions.

“I don’t see ABB as a supplier, but as a partner – and that is extremely valuable,” says Tomas Danielsson. From left: Peter Mokricki, ABB; Tomas Danielsson, Danielsson Flyreels; Patrik Wik, ABB.

ABB products work together in an integrated system that powers, controls, and protects the machine’s functions.

“We believe in the power of working closely with our customers, both large and small, to create new innovations. It has been very rewarding for ABB to be involved from the very beginning and to support Tomas as he has developed and refined Raptor,” says Peter Mokricki, Sales Manager at ABB.

A machine with many benefits

In the Danielsson Flyreels workshop in Smedjebacken, Raptor is connected to the robot cell where the fly-fishing reels are produced. Every day, the machine takes in long lengths of tangled aluminum shavings and slowly releases them as compact aluminum pucks. Tomas Danielsson no longer needs to manually remove shavings every half hour.

“Raptor can run without supervision for up to 120 hours. Machine uptime increases, and as an operator, you can focus on other tasks instead of the shavings. Raptor also improves the working environment with cleaner floors, fewer forklift transports, and lower risk of accidents,” says Tomas.

The shavings are pressed into pucks and transported to the smelter. Because the pucks are compact and free from emulsion, the risk of explosions during remelting is eliminated.

The process reduces manual work and saves both resources and costs. Today, Tomas no longer needs to clear away shavings every half hour.

From a sustainability point of view, automated shavings handling brings clear advantages.

“We close the green loop. My environmental reporting is very simple: aluminum in, aluminum pucks out, cooling liquid back. Because the shavings are pressed immediately, 99 percent of the cooling liquid can be reused in the process. This means no emulsion is trapped in the aluminum puck,” explains Tomas Danielsson.

From problem solving to business opportunity

Danielsson Flyreels is now ready to take the next step. In addition to selling fly-fishing reels, the company is launching Raptor as a product for sale. Potential customers include industries with shavings-intensive production.

“Raptor was built to solve a real problem, and we use the machine every day. That’s how we know it works extremely well,” says Tomas Danielsson, and concludes: “I chose ABB because I have great trust in the brand. They share the same philosophy I have when designing fly fishing reels: products must be of high quality and work reliably. This is especially important for Raptor, which is designed the way customers can use it immediately.”

Raptor – key facts

Raptor is an innovative machine for handling metal shavings and includes several ABB products, such as PLC AC500-eCo + with HMI CP610, ACS180 drives (7.5 kW and 0.37 kW), M3AA motors (7.5 kW and 0.37 kW), S200 series miniature circuit breakers, OT40G1-3DS load switches, OBO C2000 optocouplers, CP-S.1 24/20.0 power supply, EPD 24-A4 electronic circuit breaker, SSR10 24V DC safety relay, and SMILE 11 EA emergency stop.