1. Cobots Achieve True Industrial-Grade Performance

A major trend for 2026 is the shift toward collaborative robots (cobots) from light duty applications to full industrial grade performance levels. Today’s cobots are being deployed in complex manufacturing tasks that previously required traditional industrial robots.

This shift is powered by major advancements:

- Higher payload capacities

- Extended reach options

- Faster consistent cycle times

- Improved accuracy and repeatability

- Advanced safety and compliance technologies

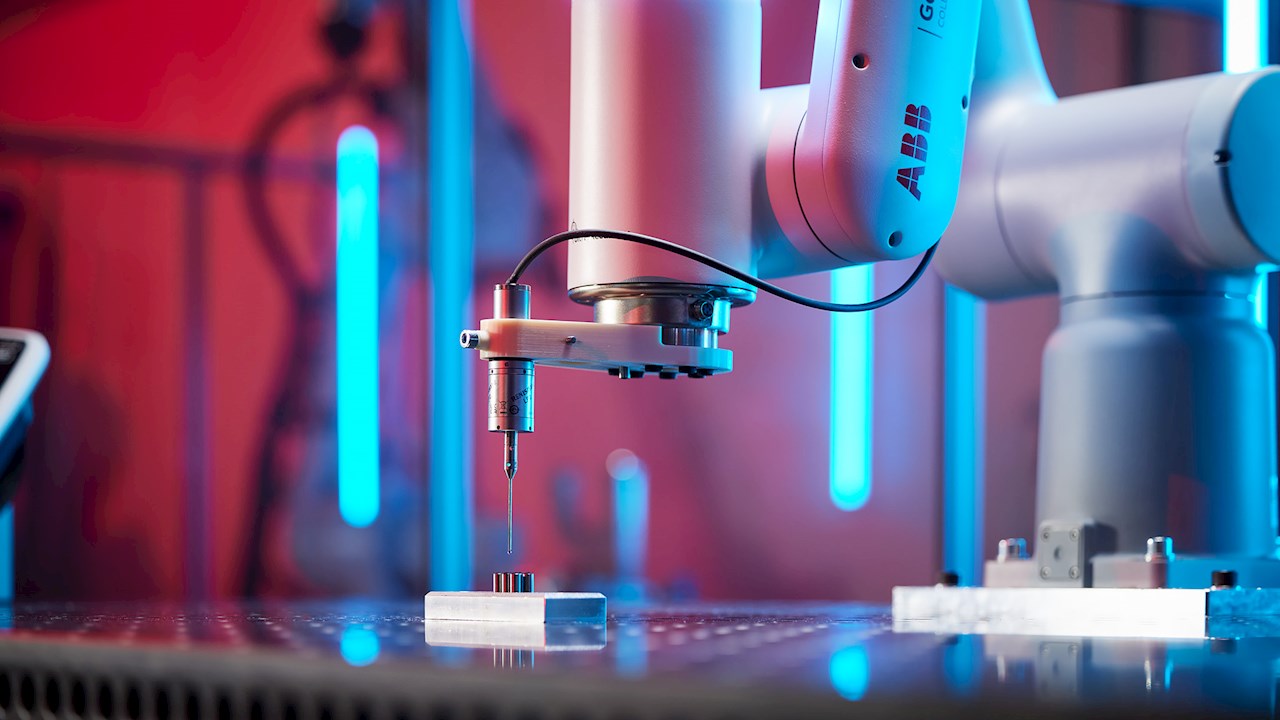

Manufacturers now expect cobots to offer industrial durability, precision motion control, and long-term reliability, not just ease of use. ABB’s collaborative robot portfolio, built on the company’s deep heritage in industrial robotics, naturally supports this evolution. With performance, safety, and endurance engineered into every system, ABB cobots are well suited for the new wave of high duty, complex applications such as precision assembly in electronics and automotive manufacturing, high precision dispensing, 3D printing, quality control, and inspection.

2. New Markets Embrace Cobots: Healthcare, Labs, Kitchens, and More

One of the most exciting developments in 2026 is the expansion of collaborative robots (cobots) into non-traditional automation environments, far beyond factory floors. Sectors that historically had little, or no automation are now adopting cobots due to their compact size, quiet operation, cleanliness, and inherently safe design.

Emerging spaces include: Cobots Accelerate Adoption in “Dirty, Dull, and Dangerous” (DDD) Environments

- Clinical and diagnostic laboratories

- Pharmaceutical workflows

- Commercial industrial kitchens and bakeries

- Research and testing facilities

- Hospitality and service environments

- Small-scale craft and artisanal manufacturing

These sectors value cobots for their precise execution, low noise levels, and extremely simple controls, making them ideal for supporting repetitive or highly sensitive tasks.

3. Cobots Accelerate Adoption in “Dirty, Dull, and Dangerous” (DDD) Environments

Across manufacturing, logistics, shipyards, and heavy industries, organizations are increasingly turning to collaborative robots (cobots) to support tasks in challenging dirty, dull, and dangerous (DDD) environments. Roles involving welding in shipyards, surface preparation, and handling hazardous materials often require exceptional consistency, safety, and precision, making cobots valuable partners in these operations.

A defining trend in 2026 is how intuitive and accessible cobots have become even in facilities without robotics expertise. Gesture based teaching, drag and drop and no-code programming, lead-through learning, and natural language interaction now enable robots to see, listen, and respond. These simplified, human-centric interfaces allow operators to set up and use cobots with the same ease as any familiar industrial tool.

ABB’s human-centric approach to cobot design including easy programming, guided workflows, and quick deployment capabilities — aligns strongly with this shift, enabling teams to integrate automation confidently and efficiently.

4. Cobots Become the Leading Platform for AI Innovation

As AI powered automation accelerates globally, collaborative robots (cobots) are quickly becoming the preferred platform for integrating intelligent robotics capabilities. Because cobots are flexible, safe, and easy to reconfigure, they serve as an ideal foundation for deploying advanced AI functions such as:

- Real-time machine vision and scene understanding

- Adaptive path adjustments

- Intelligent object handling

- On-the-fly task learning

- Predictive error detection

- Automated skill configuration

- Hybrid cloud/edge AI processing

This momentum is accelerating further with ABB’s Autonomous Versatile Robotics (AVR™) vision, which represents the next evolution of AI-powered collaborative automation. Leveraging Generative AI, AVR™ enables cobots to move beyond pre-defined programming toward autonomous learning, adaptation, and multi-task execution. By combining 3D AI vision for advanced perception, force sensing for dexterous interaction, natural language interfaces for intuitive training, and cloud-edge intelligence for real-time decision-making, ABB is transforming cobots into intelligent, versatile platforms for continuous innovation.

As a result, our cobots are not only adopting AI faster, but they are also becoming the primary environment where AI-driven robotic capabilities are developed, validated, and scaled in real-world industrial applications.

5. Mobile Manipulation (AMMRs) Becomes Mainstream

In 2026, mobile collaborative robot systems, often referred to as Autonomous Mobile Manipulator Robots (AMMRs), are experiencing rapid adoption. These systems combine a collaborative robot arm with a mobile robotic platform, allowing automation to move dynamically throughout a facility.

AMMRs are increasingly used to:

- Travel between production or inspection stations

- Support intralogistics and small batch transport

- Automate multistep workflows across multiple zones

- Improve research and laboratory throughput

- Work safely alongside people in shared environments

This merging of mobility and manipulation marks a significant milestone in the evolution of industrial automation and lays the foundation for future advanced robotic systems, including humanoid-style applications.

6. Regulations and Standards Align with Rapid Cobot and AI Growth

For years, safety standards evolved more slowly than advancements in collaborative robots (cobots) and AI-driven robotics. In 2026, this gap is closing. New global guidelines are emergingdriven robotics. In 2026, this gap is closing. New global guidelines are emerging to address:

- AI enabled robotic behaviors

- Shared workspaces for humans and robots

- Sensor based environmental awareness

- Mobile manipulator safety requirements

- Context aware risk evaluation frameworks

Clearer regulations provide companies with greater confidence when deploying larger fleets of cobots across facilities, especially in operations involving AI or mobile platforms. This increased clarity is expected to accelerate cobot adoption worldwide.

Summary

The year 2026 marks a pivotal moment for collaborative robotics. Cobots are becoming more powerful, more intelligent, more mobile, and more accessible across both traditional industrial sectors and entirely new markets. With their intuitive interfaces, AI compatibility, enhanced performance, and alignment with evolving safety standards, cobots are poised to drive the next era of automation.

FAQ

Q1: What are the biggest cobot trends in 2026?

Industrial-grade performance, AI integration, mobile manipulation, expansion into non-traditional industries, and clearer global safety standards.

Q2: How are cobots different from traditional industrial robots?

Cobots are designed to operate safely alongside humans, offering flexible deployment and intuitive programming, while industrial robots often operate in fenced environments.

Q3: Are cobots suitable for high-precision industrial tasks?

Yes. Modern cobots now offer higher payloads, faster cycle times, and improved accuracy, making them suitable for demanding industrial applications.

Q4: How is AI transforming collaborative robotics?

AI enables adaptive motion, intelligent vision, autonomous learning, and real-time decision-making in collaborative systems.