Energy efficiency is the new industrial currency

In today’s industrial economy, energy efficiency is no longer optional. Rising energy costs, tightening sustainability regulations, and increasingly competitive global markets are forcing manufacturers to rethink every aspect of their operations.

Energy-intensive sectors such as mining, cement, data centers, and water processing face ever-increasing pressure to shrink their carbon footprint without sacrificing profit and performance. Upgrading electric motors to the latest technology offers the single largest opportunity for energy savings. That’s simply because they account for 60% of global industrial electricity demand and roughly one quarter of all electricity use worldwide, according to the International Energy Agency’s Energy Efficiency 2025 report.

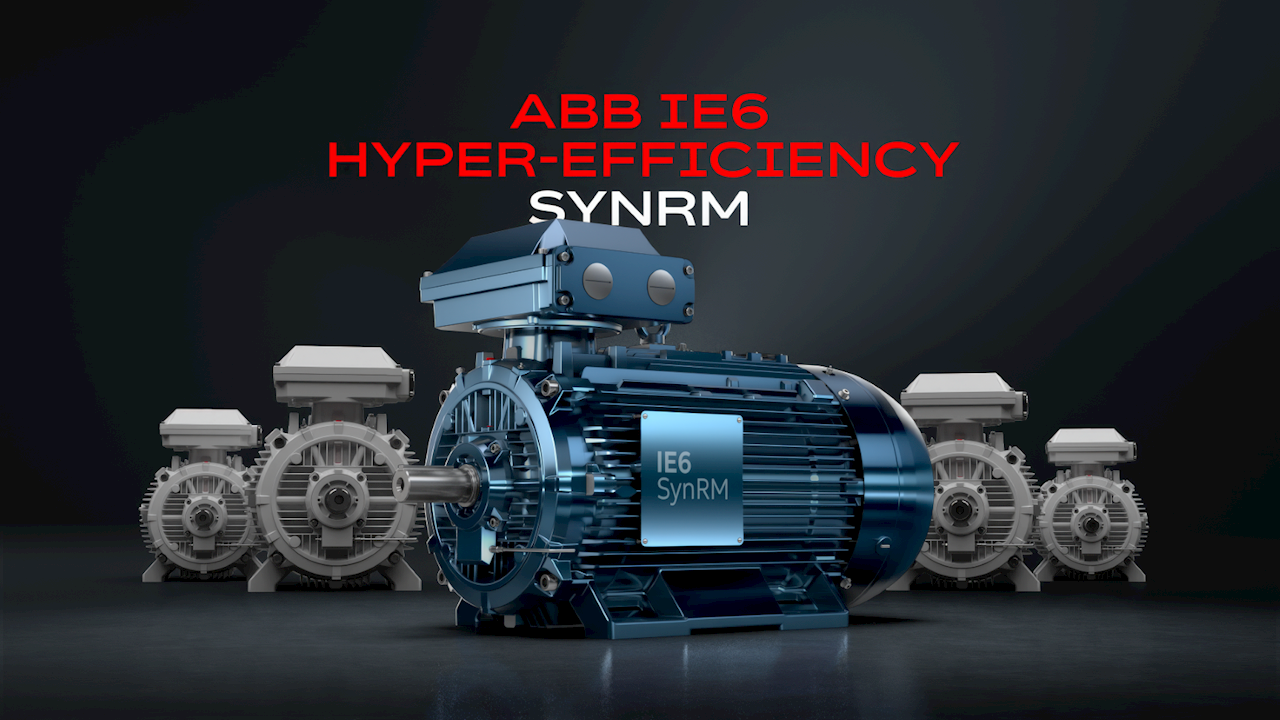

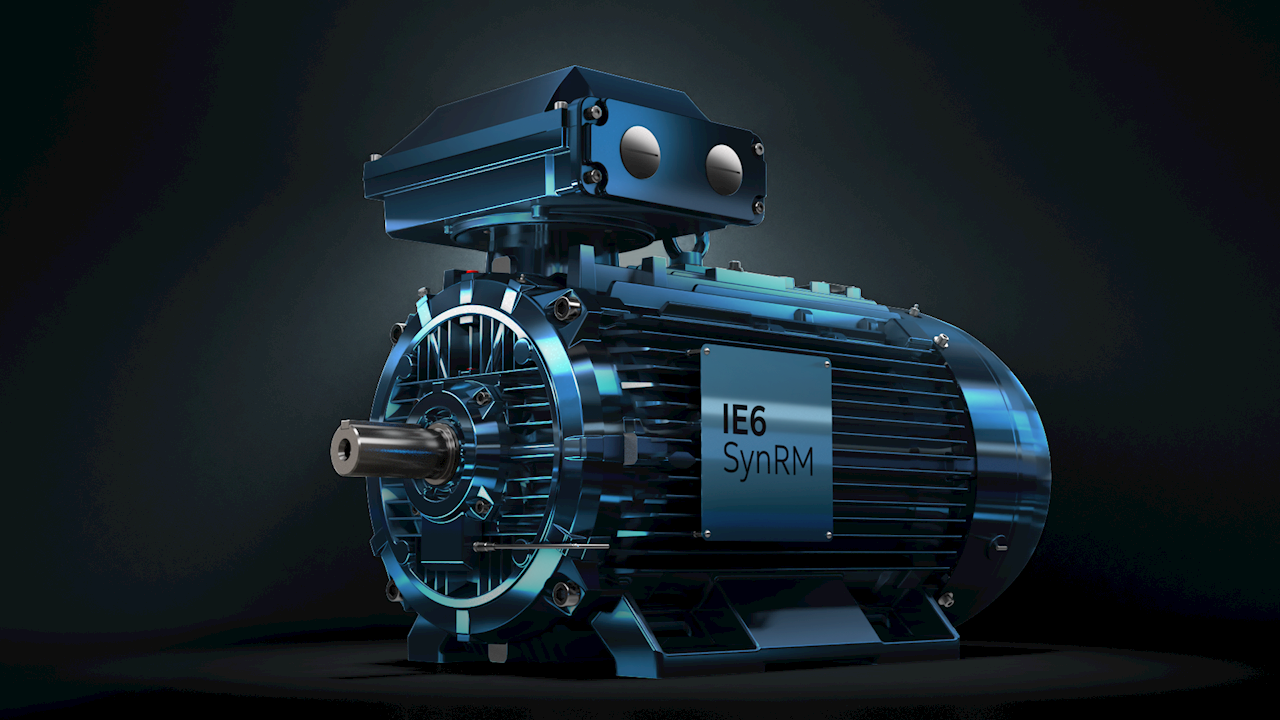

This is where ABB comes in, because we believe in making sure everything we do is always ‘Engineered to Outrun’. This ethos is made clear in our magnet-free IE6 synchronous reluctance (SynRM) motors that provide market-leading Hyper-Efficiency. They offer much more than an incremental technical improvement, making the upgrade is a strategic move that delivers immediate economic and environmental benefits.

Here are five reasons why industrial companies should upgrade now:

ABB's IE6 Hyper-Efficiency SynRM large motor range, from 110kW to 450kW

ABB's IE6 Hyper-Efficiency SynRM in Cement Plant

ABB's IE6 Hyper-Efficiency SynRM

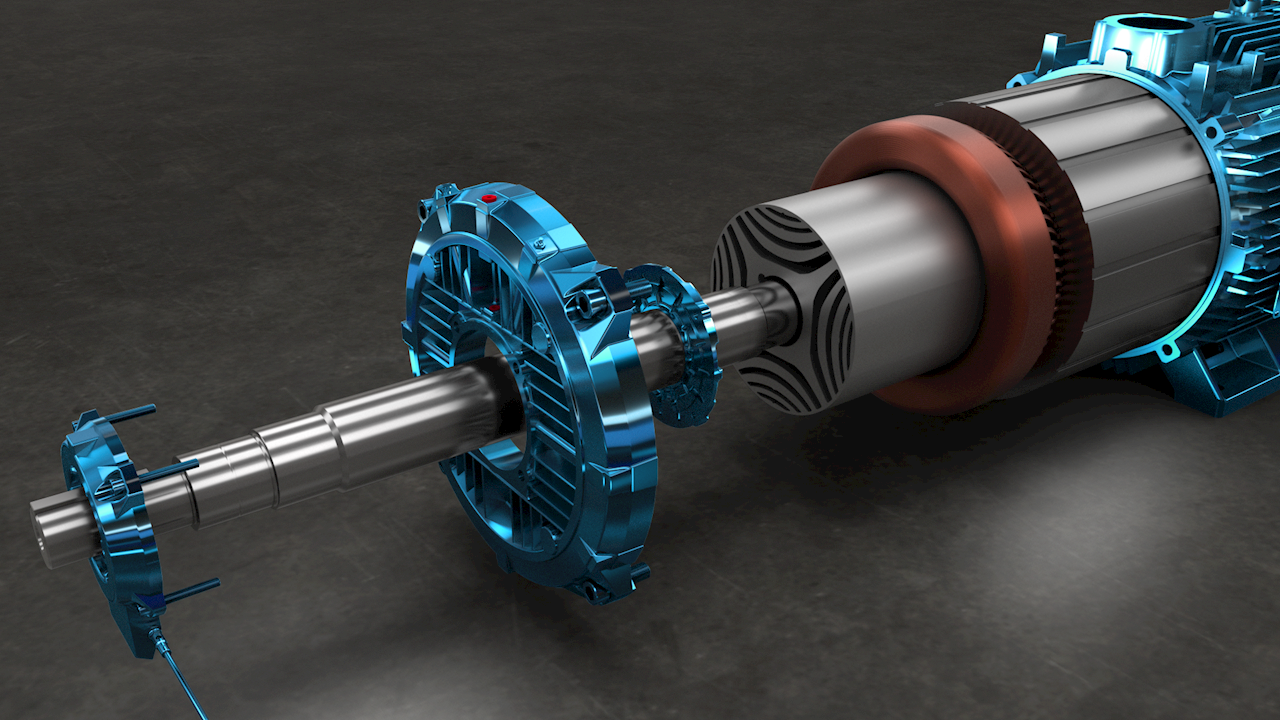

ABB's IE6 SynRM - rotor view

1. Benefit from unrivalled energy efficiency

ABB IE6 SynRM motors have been developed to meet the anticipated Hyper-Efficiency standard. That means they exceed the highest IEC efficiency classes in common use, setting a new benchmark for industrial performance.

Switching to an IE5 Ultra-Premium efficiency SynRM motor is already well proven to deliver major savings compared to an equivalent IE4 induction motor and drive package. When our IE6 SynRM motors are paired with ABB drives they offer an even greater benefit. Over a 20-year service life in a typical 110 kW application, the savings are increased by €51,200 and 92,200 kg CO2. For scale, that’s the equivalent of 21.5 gasoline-powered passenger vehicles driving for one year. These savings represent a 76% improvement over upgrading from IE4 to IE5, with the return on investment (ROI) cut to only 8 months.

Energy prices are volatile, and electricity often represents 30–50% of total operating costs in heavy industries. Every kilowatt saved boosts resilience against price shocks and competitiveness in one fell swoop. In fact, if all the 300-million plus industrial electric motor-driven systems operating today were replaced with IE6 motors, worldwide electricity consumption could be cut by up to 10%.

2. Fast payback and strong ROI

Cost is one of the chief barriers to adopting new technology. However, customers find the most powerful argument for switching to IE6 SynRM technology comes when they look beyond the upfront investment and consider the motor’s total cost of ownership (TCO).

For an IE6 Hyper-Efficiency SynRM motor, the upfront cost is just 2% of its TCO. Maintenance accounts for 1% and the remaining 97% is the cost of energy to run it. The more efficient motor soon pays for itself, sometimes in only a few months when energy prices are high. It will then go on to generate major savings for the rest of its working life. For companies operating hundreds of motors, the cumulative financial impact is transformed into a competitive advantage.

When an operator needs to replace older aging or failed motors that might have outdated IE1 or IE2 ratings, then the cost of replacing them with new high-efficiency motors, such as with IE4 Super-Premium efficiency induction motors, is financed straightaway by the very significant energy savings.

However, when it comes to considering what level of efficiency to specify for new motors it makes sense to specify the very best. Because the extra incremental cost for specifying an IE6 Hyper-Efficiency SynRM motor over an IE4 induction motor is paid back within months.

3. Lower maintenance and increased reliability

Downtime is the enemy of productivity. IE6 SynRM motors are designed for reliability. The rotor has no windings, magnets, or slip rings, eliminating common failure points found in other motor types. This results in lower maintenance costs and fewer unplanned outages.

A further benefit of SynRM motors is that they run cooler than conventional motors, reducing thermal stress on bearings and insulation. Cooler operation extends motor life and minimizes lubrication needs. For industries where uptime is critical, like petrochemicals or mining, this reliability can make or break the performance of a motor.

4. CO₂ reduction and ESG Compliance

Sustainability is on every operator’s agenda, but it’s more than just a passing buzzword. Governments and investors are demanding measurable progress toward decarbonization. Upgrading to IE6 Hyper-Efficient SynRM motors is one of the fastest ways to cut emissions without disrupting production. Every kilowatt-hour saved reduces CO₂ emissions by around 0.4 to 0.6 kg, depending on the local energy mix. For plants with 100 motors or more, this can mean thousands of tons of CO₂ avoided annually.

Every IE6 SynRM motor is included in ABB’s EcoSolutions™ portfolio, which includes third-party-verified Environmental Product Declarations (EPDs) to simplify reporting and regulatory compliance. The motors are 98% recyclable by weight, and their manufacture uses low‑carbon and recycled copper, reducing embedded emissions by up to 200 kg of CO₂ for each 75 kW unit.

On top of that, the SynRM’s design means the motor doesn’t use magnets or rare earths. By delivering high performance without these materials, customers can reduce electricity use, cut CO₂ emissions, and improve productivity without compromising on performance.

5. Flexible drop-in upgrades

ABB’s IE6 SynRM range makes efficient motor technology available as a standard solution for pumps, fans and compressor applications in large frame sizes 280 and 315 across a power range of 110 to 450 kW for speeds up to 3000 rpm, and 110 to 400 kW for speeds up to 3600 rpm.

The IE6 SynRM is the same size as the equivalent induction motor, making it an easy and straightforward drop-in upgrade for legacy motors.

Cement plant produces concrete evidence for energy savings

The cement industry currently represents about 7% of carbon dioxide (CO2) emissions globally and is the third-largest industrial energy consumer, that’s according to the International Energy Agency (IEA). That means the potential for energy savings, and avoidance of the associated CO2 emissions, is also huge. Therefore, ABB has explored the benefits of switching to our IE6 Hyper-Efficiency SynRM motors at a large European cement plant producing up to 3 million tonnes per annum (Mtpa).

Across the plant, numerous low‑voltage motors work tirelessly behind the scenes in applications ranging from conveyors and pumps to fans and dosing systems. Most of them could be direct-on-line (DOL) models with an IE2 energy efficiency rating.

If the plant’s motors were upgraded to IE6 SynRM and variable speed drive (VSD) packages, then our simulations show that the annual energy usage would be slashed from 93.30 to 67.65 gigawatt-hours (GWh). That 27.5% saving would save the plant more than Euro 2 million in energy costs per year (based on an energy price of Euro 0.084 per kilowatt-hour (kWh)). If we anticipate a lifetime of 20 years, then the savings could be Euro 40 million. Of course, the higher the local energy price then the higher the potential savings.

Technology for today, not tomorrow

Upgrading to IE6 SynRM motors is one of the most impactful steps industrial companies can take today. It’s a proven technology that delivers energy savings, cost reductions, and CO₂ cuts from day one.

In an era where energy efficiency equals business resilience, the question is no longer “Can industry afford to upgrade?”—it’s “Can industry afford not to?” The time to act is now.