ABB’s new ring bus architecture with static UPS is designed to provide reliable and available power to the most mission critical applications, like data centers, at minimal costs. Currently deployed, this unique system can be expanded at will – without limits to the number of UPSs or distance between them.

Silvio Colombi ABB Electrification Products, Quartino, Switzerland, silvio.colombi@ch.abb.com

Data centers and other mission critical systems rely on the stable electrical performance of the selected critical power architecture at all times. Technological advances focus on maintaining or improving performance and reliability while reducing total operational costs; this includes lowering the cost of equipment and maintenance, and energy.

Often, energy efficiency is a fundamental driver of innovation in the uninterruptible power supply (UPS) market, together with reliability and preventive maintenance. Improvements in operating efficiency can generate massive savings; an annual energy savings of $13,000 is achieved for every MW of installed UPS power (eg, $0.15/kWh) for each percentage point of improved efficiency. The reduced need to cool the system results in further savings.

Keenly aware of customer’s needs, ABB pursues all avenues to maximize efficiency when designing systems. From component selection through the converter topologies and operating modes to the critical power architectures, ABB’s novel ring bus configuration with static UPS addresses these needs.

Ring bus architecture basics and evolution

To increase reliability and availability of power supply to critical loads, many and varied UPS configurations have been developed: Paralleled Redundant (N+1 System), Block Redundant (Catcher System), Shared Redundant (4N/3 System), System plus System (S+S)→1. Each configuration has benefits and limitations. Traditionally, the ring bus or ISO (isolated) Parallel Architecture has only been deployed with rotary UPS systems, mainly due to the substantial technical challenges associated with the use of static UPSs.

The limited fault current capability and the potential back-feed of power from the output of the UPS to the dc link have posed barriers to design engineers. However, in 2014 efforts were made to rectify these difficulties. An initial version of ring bus architecture with static UPS became available to customers. Other design variations have also been explored since 2015. Currently, ABB is the sole supplier of the ring bus architecture with static UPS.

As configurations increase in their scale of power availability, so typically does cost. Hence, with reliability and power availability paramount, data center operators face a dilemma about architecture choice. These decisions are made more easily by mapping performance, availability and CapEx-OpE based on analyses of multiple factors→1.

Load sharing

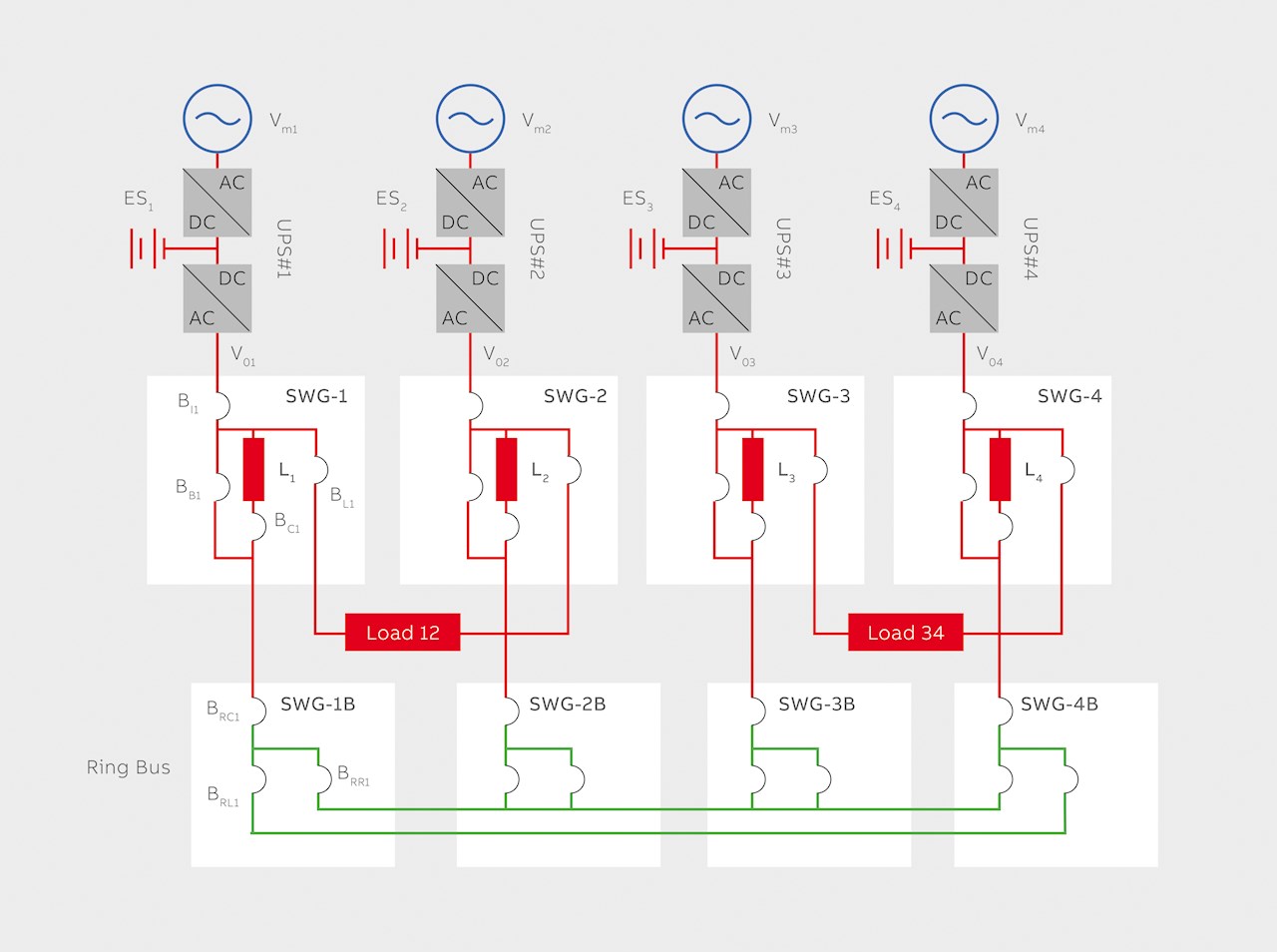

A ring bus technology with static UPS in a system with 4 UPSs and two dual corded loads functions so that every UPS can supply its local load cord and also transfer active and reactive power to the ring bus through a choke→2. The intent is to share the local loads equally between the different UPSs without any communication using droop controls, in particular frequency versus active power and voltage versus reactive power. This removes any limitation on the number of UPSs in the system and the distance between them. Also, the totality of the load is shared across all the UPSs in the ring, even in enormous rings. In large systems with other architectures, blocks of UPSs need to cope with the current limitations of low voltage (LV) breakers. The ring bus chokes are instrumental for the wireless load share as they make the impedance inductive.

If the second dual corded load is smaller, then UPS 1 and 2 push active power to the ring while UPS 3 and 4 receive active power from the ring→2. The net result is four UPSs that are equally loaded. In steady-state, the frequency of all UPSs is equal and the phase shift between the various UPS voltages depends on the sign and amount of active power exchanged with the ring bus. If the loads are perfectly balanced and all the UPSs are operational, there is no circulation of power through the chokes.

Fault isolation

The ring bus chokes are essential for the wireless load share and for fault isolation. A fault can occur anywhere in the system, eg, on UPS output (A), on the ring bus (B)→3. No single points of failure should be allowed to cause a partial or total load drop. The worst case scenario is a phase-phase short circuit on the ring bus→3; every UPS needs to provide fault current through its choke while supplying its cord of critical load. The quality of power delivered to the critical load must remain within the defined voltage window (VW) during faults too. Therefore, VW, fault detection time and fault isolation time are clearly related. When standard relays and breakers are used, fault detection and isolation times are typically one-half and two cycles, respectively. In such cases and during a phase-phase short circuit on the ring bus the UPS output current must remain at the limit of the inverter current limitation regime. This criterion determines the minimal inductance of the ring bus choke. If a fault occurs on the output of one UPS (A), the other UPSs are decoupled from that fault through two chokes →3; clearly a better scenario.

Ring bus architecture protection

To locate and isolate faults (by opening the appropriate breakers) in the system a number of circuit breakers (BI1, BBi, BCi, BLi, BRCi, BRLi, BRRi for every UPS) and the related logic and relays are included. As previously stated, if standard relays and breakers are used for fault detection and isolation, detection and isolation times are typically one-half and two cycles, respectively. This will differ, however, if other switches are used→4.

The bypass is the ring

Even though the most important source of faults in data centers is human error, elimination of errors is impossible; so data centers must be equipped with superior fault tolerant systems.

With the use of breaker BBi to bypass a choke when a given UPS has failed or is under maintenance, the quality of the voltage on the local load of concern can be improved because the voltage drop on the choke is removed. Because the bypass is the ring, synchronized inputs are not required, nor is there a need for connecting switchgear in parallel. The relays and breaker network make a superior fault tolerance possible, ABB’s unique self-healing structure is not only insensitive to an initial fault, but also robust enough to withstand subsequent faults.

Measuring performance: the VW pass-fail criteria

Power quality requirements depend on the load; in data centers these are the servers or, more precisely, the power supplies inside the servers. In essence, requirements specify the operating region and prevent interruption of the IT equipment. Depending on the power supplies used, requirements can differ→5.

Starting when a fault is applied, a time of X[ms] of clemency is considered from when the voltage starts to distort, then the rms voltage of the first cycle after clemency is measured and has to be > Y percent of the nominal voltage Vnom. As an example, applying the CBEMA requirements to a nominal voltage of 240V, 168V/20ms is obtained, ie, success is defined by an rms voltage greater than 168V measured on the first cycle 20 ms after the fault→5.

The choice of power supply configuration is critical for data center operators; especially the VW safety margin because the VW must be fulfilled under any fault condition; even the worst case scenario.

The utilization rate (UR) is related to the VW, the tighter the VW, the lower the UR, eg, a UR > 80 percent based on the CBEMA VW (70 percent – 20ms) can typically be reduced to 60 percent based on a VW (86.5 percent – 10ms). Clearly, if faults on the ring bus could be excluded by design, the UR could be increased substantially, but this is not realistic.

Operation modes, validation and results

When one UPS is offline due to maintenance needs or a fault→6, dual UPS power is fed to the loads and the remaining UPS provides balanced power. In steady state, the circulation of power from the ring to one side of the load occurs through the bypass breaker (BB1) whereas the instant the fault occurs, the power starts circulating through the first choke (L1), which is then bypassed→4.

If operating conditions exist under unbalanced load→7, the second dual corded load is smaller and UPSs 3 and 4 need to push power to the ring while UPSs 1 and 2 receive power from the ring. Hence, the global load is shared by all four UPSs – a clear benefit.

Developmental process

Seizing on innovation, ABB initiated the development of this unique ring bus architecture with an innovative program in which a few initial patents have been granted; a small power test rig was constructed to verify the hypothesized wireless load sharing results. The developmental program began with the design of a full scale system of 4 x 200kW UPSs in Riazzino, Switzerland and a 4 x 1000kW UPS in Plano Texas, USA→8.

Taking into account all necessary components (UPS, chokes, breakers, relays, PDU, etc,) these test centers were instrumental during the developmental phase and are still in use today to demonstrate and promote the ring bus architecture to customers and consultants alike. Relying on a comprehensive interface system that includes a synoptic screen that displays the status of all breakers, UPSs and electrical quantities of interest, ABB delivers a highly functional system.

Further advances include the development of a complete system model that employs transient simulation software to analyze system performance in fault and load-shifting events and power transfer capability for ring bus systems of any size. Other models have been developed to perform reliability estimation comparisons of ABB’s ring bus system with those of known architectures, thereby confirming that isolated parallel configurations have superior reliability due to the virtual lack of interaction between UPSs. The UPSs do not communicate: the only interactions, from a power connection perspective, are through the extremely reliable ring bus chokes.

Compelling results were obtained during ABB’s test of a phase-phase short circuit on the ring bus architecture with 4 UPSs→9. The pass-fail criteria used in this worst case is a voltage window of 86.5 percent – 10ms. With a nominal voltage of 235V, this translates into a voltage of 203.3V. Every 1MW UPS is loaded with 600kW. In this case, the voltages V1, V2 and V3 on the critical load (downstream from the PDU) are represented on channels 1, 3 and 5 which show rms voltages of 218.2V, 205.4V and 230.6V, respectively, when measured 10ms after the fault→9. The utilization rate, with this voltage window, is 60 percent – an excellent result.

Static UPS versus rotary UPS

A comparison of a ring bus architecture using rotary UPS with ABB’s ring bus →10 highlights the benefits of double conversion UPS: lower initial and maintenance costs and improved load protection.

Comparison with known architectures

ABB’s novel ring bus architecture with static UPS is more reliable than other solutions, requires less initial investment in materials and installation and consumes less energy during operation. Fewer units are needed and each unit functions at top efficiency; all these features translate to a lower total cost of ownership.

Specifically, the ABB ring bus architecture is a self-healing structure that offers:

• ultimate fault tolerance

• no single points of failure

• lower number of UPS modules

• higher UPS utilization rate and less stranded system capacity

• simple and safe scalability

• optimal utilization of breaker current capabilities

• concurrent maintenance for critical path equipment

• no communication among UPS

• no limitations on the number of UPS and their distance

• total system load shared across all UPS modules

• no need for synchronized inputs

• no needs for paralleling switchgears

• potential fault current limitation

ABB’s role as technical leader

Currently, ABB holds several patent families on the ring bus technology that cover the current implementation as well as future concepts. In this way, costs, feasibility and viability of this architecture is optimal today and in the future mission critical system market. These gains will ensure that ABB continues to fulfill its role as a global technical pioneer, supplying customers with the best solutions. By providing power reliably and efficiently, the unique ring bus architecture with static UPS does just that.