ABB has introduced a wireless condition-monitoring bearing sensor that enhances safety and supports evidence-based decision making. Information delivered by the sensor allows customers to quickly assess the health of their bearings and decide when to schedule maintenance. Safety is enhanced since service personnel do not need to get close to operating machinery to assess a bearing’s condition.

Michael Konruff ABB Motors and Generators Greenville, SC, United States, michael.konruff@us.abb.com

Mounted bearings play a critical role in many applications, such as material handling in grain storage, the food and beverage industry, and mining. Downtime due to a failed bearing can be quite costly, not only due to lost production but because of secondary damage. Many times, bearings are located in hard-to-access or remote locations, making regular inspections difficult and time consuming. In view of these challenges, ABB has developed the Ability Smart Sensor for Mounted Bearings – part of the ABB Ability Digital Powertrain. The sensor allows customers to monitor bearings regardless of their locations; furthermore, it provides analytics that open the door to early identification of potential issues with associated equipment.

What customers want

Although ABB has applied sensors for its mounted bearing products previously, there were many unknowns before starting the development of the current project. To gain more knowledge regarding customer needs and requirements, the company performed an extensive “Voice of the Customer” polling. Over 100 customers of different types were interviewed. People interviewed included maintenance managers, operations managers, industrial distributors, reliability engineers, OEMs and others that use mounted bearings. The data from the interviews was aggregated into different buckets based on customer needs and secondary interviews were conducted to validate and prioritize the findings.

The results indicated that customers desire help when it comes to maintaining and troubleshooting bearing products. One of the major reasons for this is that demographics are changing. Highly skilled maintenance mechanics with years of experience, who could often diagnose bearing issues based on small alterations in sounds or temperatures, are nearing retirement age and companies are not generally able to replace them with like-minded workers. Furthermore, when customers do find replacements, the newer workers tend to be computer savvy, but have lower mechanical aptitude.

Also, many customers don’t understand condition monitoring technology or how to evaluate condition monitoring data. Some customers outsource this task but doing so is very costly. Often the analysis is performed by people who aren’t experts in bearings. While some customers have already adopted a condition monitoring program, many don’t have a formal program. They either don’t have the resources or consider the current cost of analysis too high.

Most customers, however, see a benefit when it comes to monitoring their asset health and the uptime that results. Also, the Internet of Things is just getting underway and many of the customers who were interviewed believe that it will have a significant impact on reducing the barriers that have prevented condition monitoring solutions from becoming widespread.

The “Voice of the Customer” survey pointed ABB to a solution: an easy-to-use, low cost condition monitoring system would fill most customer requirements. That seems pretty straightforward, but is it possible? As mentioned, ABB had previously had a sensing solution for bearings, but its market acceptance had only been lukewarm. Why would a new solution be any different? The answer is that technological advances in electronics, connectivity, sensing, and the Cloud have changed the game.

Improved safety and reduced costs

A new bearing sensor was developed as a collaborative effort between ABB and external vendors. ABB now offers a wireless condition monitoring solution that allows customers to quickly assess the health of their bearings. The sensor will let plant operators know when a bearing’s performance shows signs of trouble, thus allowing the operator to decide when to replace it to avoid catastrophic failure, all of which provides a significant benefit from a cost and safety standpoint.

Because the sensor is wireless, installation costs are lower than is the case with traditional sensor technology. Installed sensors also eliminate the need for maintenance visits to monitor equipment or to take readings with handheld tools, and built-in diagnostic capabilities reduce the need for condition monitoring analysts. Moreover, since machines must be operating to take condition indicator readings, safety is improved for reliability personnel as they don’t need to get close to machinery or use their fingers to gauge temperatures. All of this adds up not only to a safer service environment, but one designed to help customers make better decisions. Indeed, thanks to information delivered by the new Ability Smart Sensor, customers will be able to determine how running equipment under different operating conditions influences machine life, when to order spare parts and how to optimize maintenance and repair schedules.

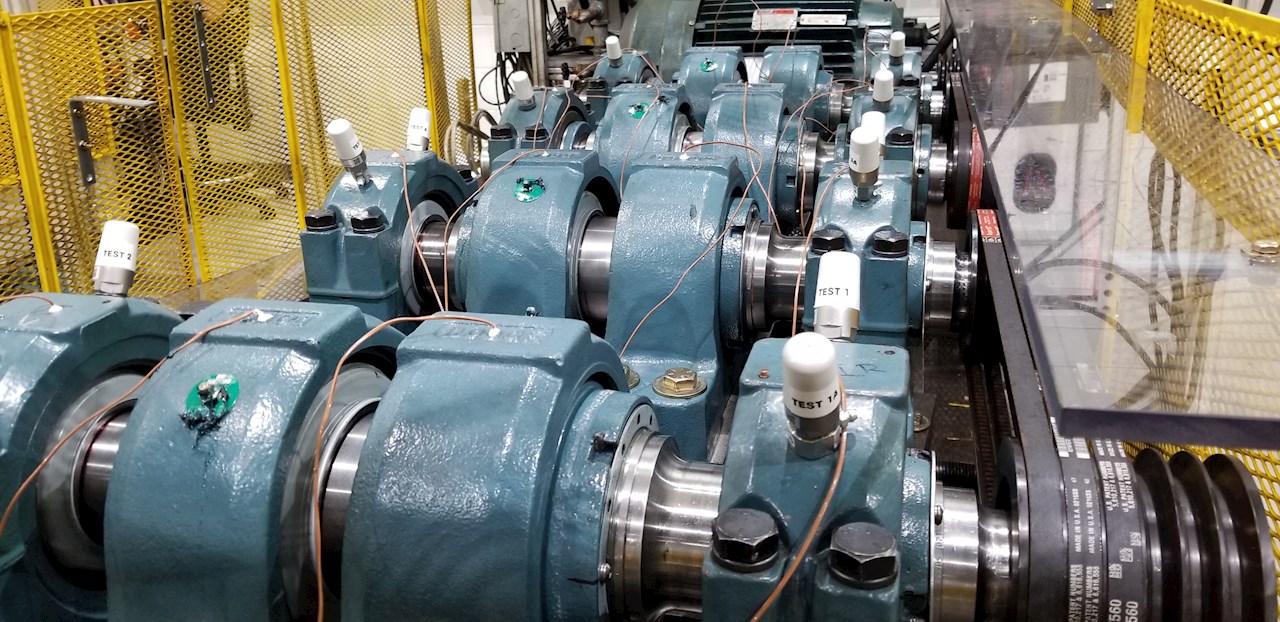

The sensor is very simple to install and mounts directly onto a bearing’s housing using simple tools →1–2. Newer bearing housings will be modified to accept the sensor and a retrofit adapter will be available for the installed base as well. The sensor, which is powered by a non-replaceable small lithium battery that has a life expectancy of three years, includes accelerometers to measure vibrations, and temperature sensors to measure bearing temperature as well as temperature inside the sensor. The sensor housing is sealed to maintain its ATEX certification.

From quick views to deep dives

Bluetooth protocol is used to connect to Android or iOS mobile phones using the same app as the Smart Sensor for Motors or through a gateway to connect to ABB Ability or customer reliability systems. Life is made easier for customers since they can log into one ABB Ability interface and check the condition of their bearings or motors. Depending on the capabilities of plant reliability people, there are options for viewing the vibration and temperature data. The mobile app provides a quick view of condition health in a stop light format and also provides some basic information regarding temperature and vibration measurements. If customers want to view more detailed information, the application on ABB Ability allows more sophisticated users to look at trend lines or extract the data in order to perform their own analysis.

Embedded into an on-board microprocessor are advanced algorithms that ABB developed to detect various faults in the bearing. Validation of the algorithms and sensor performance was accomplished through extensive testing in the Greenville Advanced Development Lab on bearings with seeded faults. The true test of performance is how the sensor works under actual operating conditions so several beta test sites at key customer locations were used to further validate the sensor and application.

Feedback has been very positive. The sensor has 30 days of data storage capacity, so customers can look at trends directly from the sensor. New versions of firmware can be installed by an over-the-air feature built into the sensor.

The Smart Sensor for Mounted Bearings is the latest technology offering in the ABB condition monitoring arsenal and complements the Smart Sensor for Motors. Both sensors provide asset health conditions that can help ABB customers maximize uptime.