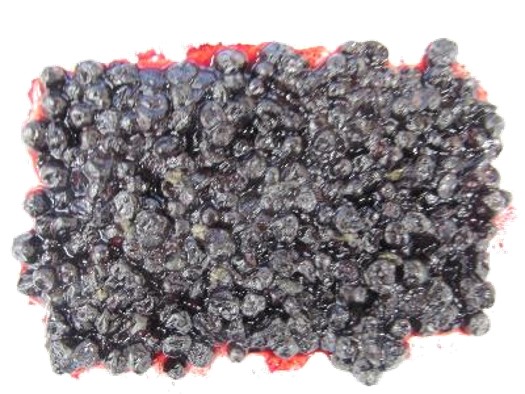

Fruit flies are very small, making them nearly impossible to see with the naked eye against a variable background like a crate of blueberries. Detecting the presence of fruit flies and removing them is a major challenge for produce growers, but now there’s a technological answer to this problem.

ABB has developed a system using spatial imaging combined with spectroscopy to generate an image that clearly distinguishes flies from fruit. The combined technology is known as hyperspectral imaging and could represent a major improvement in quality monitoring for the produce industry. The system could eventually be coupled with artificial intelligence to not only detect the presence of insects on fruits and vegetables but also trigger alarms and suggest remediation processes.

This was one of the many interesting examples of digital technology in the food and beverage industry presented at ABB Customer World in Houston the week of March 4th. There are several forces driving the digital trend in F&B. These include increased connectivity and internet bandwidth, computers capable of handling data analytics algorithms, and the proliferation of inexpensive sensors to collect data from devices in the field and on the plant floor.

ABB’s Rich Dovi, Jon Rodriguez and Roger Gaemperle showed several real-world examples that demonstrate how the industry has picked up the pace of digital adoption.

One project involved improving batch cycle times, quality and yield. The plant in question had experienced problems on all these fronts due to repeated manual adjustments to manage acid levels and viscosity. They were limited to producing two batches per week due to a highly iterative process. Following analysis using ABB’s reactor fingerprint and optimization service, the company identified a fix: increasing vacuum on the processing line to pull off more water, which in turn reduced batch time to 40 hrs. The firm is now producing three batches per week with better consistency.

In another process, ABB used artificial intelligence and machine learning derived from the chemical and pulp and paper industries to predict end-of-batch quality. The analytical model learns the various ways that batches can go wrong (i.e., failure modes) and identifies potential problems in real time. This allows operators to take corrective action immediately rather than waiting until the end-of-batch process.

ABB is also working to integrate factory data into blockchain solutions for end-to-end transparency. Data from the blockchain enable users to do production planning based on real-time demand feedback from retailers, for example. It could also be used to store and share cold-chain integrity data of products in transit.

Blockchain can also dramatically simplify the process of determining the source of a given product or ingredient. A test performed by Walmart to trace the origin of mangoes, for example, showed that while a conventional investigation took more than six days, the blockchain solution provided an answer in 2.2 seconds.

Digitalization in F&B is also being applied to energy optimization. One example of this is in a greenhouse located in the United Arab Emirates. Previously the facility only tracked aggregate energy use, mostly for cooling, but the installation of sub-metering provided data on specific end uses. More data was gathered using sensors to measure CO2 consumption, water flow and treatment, HVAC performance and other factors. The resulting data stream was fed into a cloud-based data visualization system that provides various analytic capabilities such as historical analysis to compare growing seasons.

These examples illustrate the tremendous potential that digitalization holds for the F&B industry, but it’s important to start the digital journey with a clear set of objectives. Whether it’s energy use, equipment availability, yield, quality or other related metrics, once they are established the business can focus on solutions aimed at achieving and exceeding those targets. As noted earlier, F&B can also leverage many of the techniques used in other industries.

As the cost of sensors, cloud storage and communications continues to fall, there will likely be a proliferation of sector-specific tools to address the unique needs of each F&B market segment. The time to get started on the digitalization journey is now.