Following a recent investment and transfer of knowledge and skills, ABB South Africa’s motor and generator factory in Alrode, near Johannesburg, is now fully compliant with the DTI's “greater than 70% local sourcing” regulations.

ABB’s commitment to the region also includes the modernisation of local manufacturing facilities, comparable to the best in the world. This has been demonstrated in the Alrode factory’s upgrade. Combining the best available materials with superior technology, the electric motors and generators produced in the Alrode factory will operate reliably in every industry and application, despite challenging process or application environments, with the lowest lifecycle cost.

Customer benefits

Local manufacture offers many benefits to customers, from ABB’s improved broad-based black economic employment (B-BBEE) rating to reduced costs, improved efficiencies and shortened turnaround times which result in better after sales service and access to spare parts.

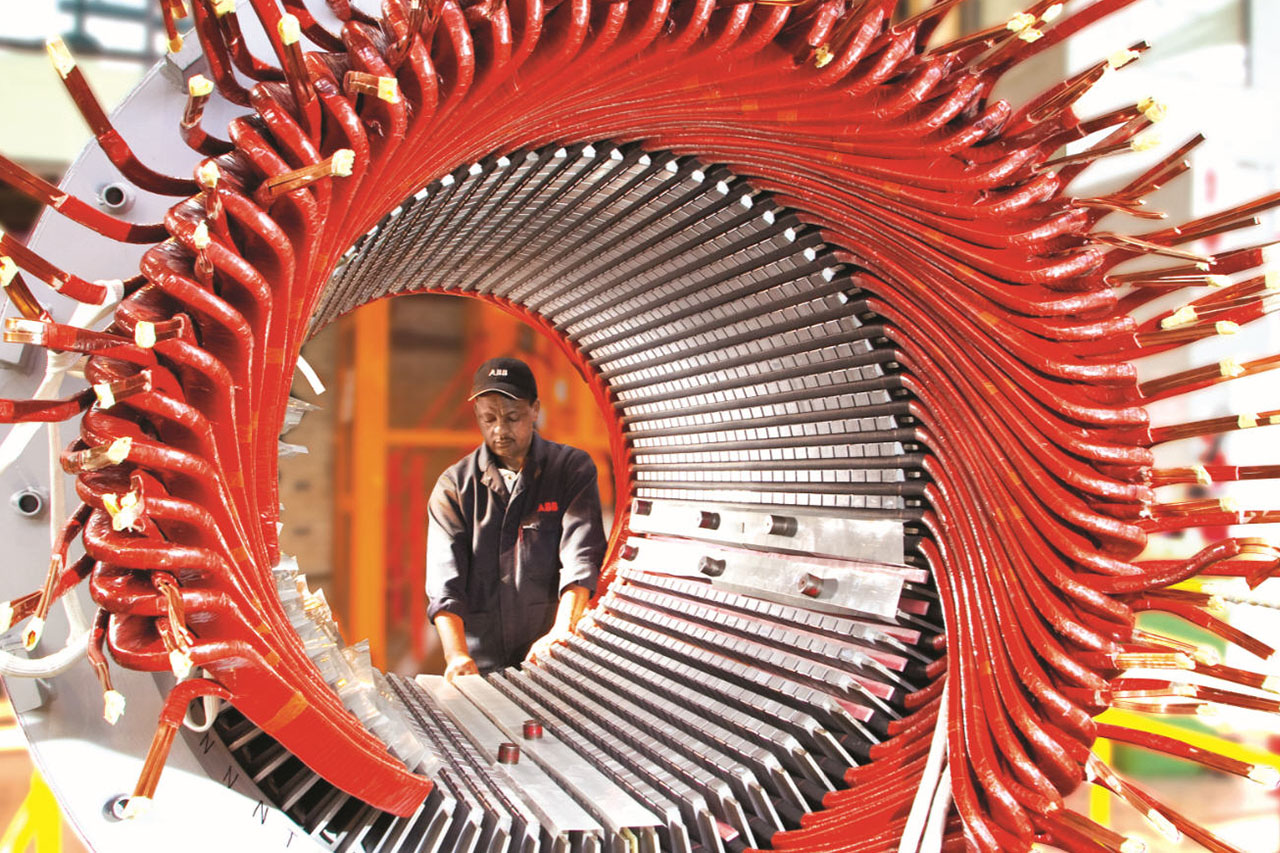

The motors and generators section of ABB’s 6000 m2 Alrode factory is equipped with a massive 15 tonne, high speed, balancing machine; cranes with lifting capacities of 80 tonnes; and an impressive 6 MW, 13,8 kV load test bed facility. The factory also houses ABB’s new dedicated, state-of-the-art, coil shop which produces the coils used within electric motors and generators.

This upgrade means that ABB’s Alrode factory can manufacture – and test inhouse – large induction and synchronous motors, and generators capable of producing between 550 kW and 20 MW of electricity, for power utilities, heavy industries and mines within South Africa and further field.

The factory can also support specific customer requirements by designing and manufacturing, to order, unique motors and generators tailored to local conditions, including the highly customisable “Q” range of engineered modular motors, to directly replace older, obsolete equipment, or to meet the demand for increased performance.

Product lifecycle management and repair services

ABB’s product lifecycle management model is designed to provide proactive service offerings for increased availability and performance. The company offers a dedicated field service programme which supports installation, supervision, commissioning and a full range of field-bound maintenance services, designed to increase the reliability of the motors and generators already in use.

The company’s after-sales and repair services ensure that ABB, or non-ABB, motors and generators deliver maximum availability throughout their lifetime. Through the application of the latest design techniques and insulation methods, motors and generators repaired by ABB stand to have a longer life within the parameters of their original design criteria.

The Alrode factory is also able to offer a full range of genuine OEM (original equipment manufacturer) spare parts, including commissioning parts, operational parts, preventative maintenance kits and capital parts. ABB can also recommend upgrades or replacements which offer the customer enhanced performance over their operational lifetime.

Being fully compliant with the DTI’s requirements bodes well for the company since it can now offer its products and services to a greater number of customers and can bid for more tenders. Building an agile and customer-focused organisation is part of ABB’s focus on customer centricity. It will increase ABB’s competitiveness in the market and create new opportunities for export into neighbouring countries.

ABB’s Alrode factory was established in 1981 to produce components for high voltage (HV) motors and generators for local and international customers. Since its inception, the facility has produced thousands of large and powerful motors and generators for ABB’s local and international customers.

About ABB

ABB (ABBN: SIX Swiss Ex) is a pioneering technology leader with a competitive offering for digital industries. With a history of innovation spanning more than 130 years, ABB is a leader in digital industries with four customer-focused, globally leading businesses: Electrification, Industrial Automation, Motion and Robotics & Discrete Automation, supported by its common ABB Ability digital platform. ABB operates in more than 100 countries with about 147 000 employees. www.abb.com