ABB’s 1700 V LoPak1 modules, with longer lifetime and better electrical performance, are available from June 2020, with the introduction of an optional pre-applied thermal interface material (TIM).

TIM provides better thermal conduction than heat conductive paste (table 1) and, after the drying-out process, is solid at room temperature allowing for easy module handling and installation by the customer (figure 1). It is applied during module fabrication by ABB Power Grids and compatible with automated stencil printing, providing the process repeatability required for volume production.

| Table 1 – Comparison on materials used between base plate and heat sink |

||

|---|---|---|

| Appearence |

Paste |

TIM |

| Color |

White or grey |

Grey |

| Base material |

Silicone fluid with filler |

Phase change material with filler |

| Consistancy@room temperature |

Viscous |

Hard |

| Thermal Conductivity (W/mk) |

0.8 - 3.0 |

5.2 |

TIM plays a critical role in the heat flow path, which effectively controls the temperatures within the module body by carrying the heat from the active devices to the external world (figure 2). The flow of heat through the module is determined by the individual layers that are in contact along the path. The base plate / heat sink interface contributes the highest amount of thermal resistance for the entire module, when heat conductive paste is used. The paste is a thick, viscous material applied manually by the customer using stencil printing.

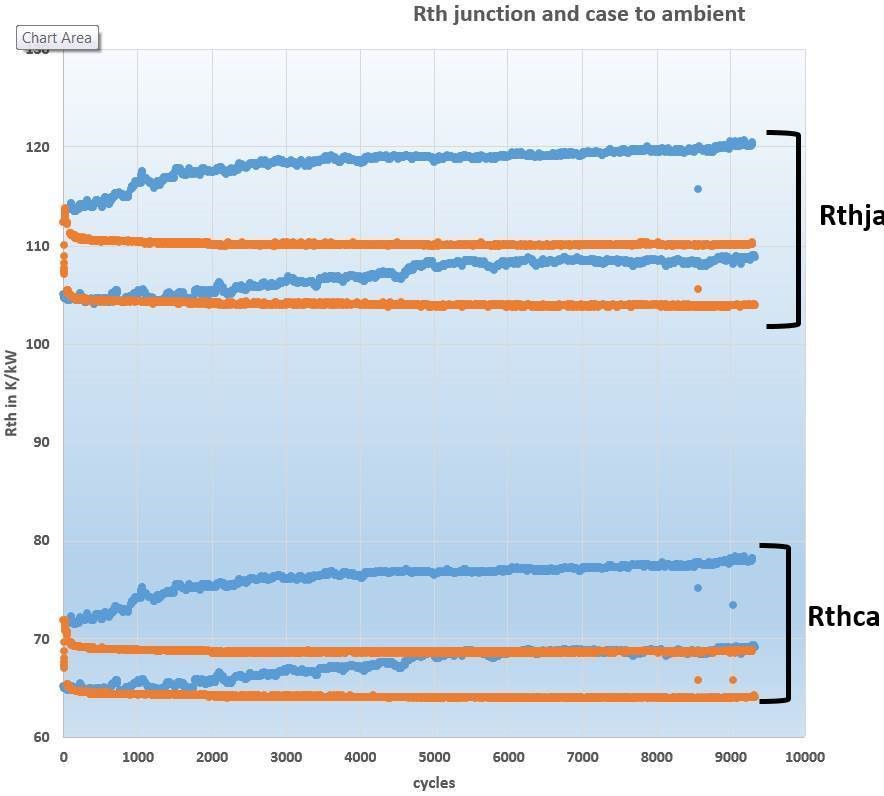

Following a temperature cycling test of 9,400 cycles (table 2), where TIM is used instead heat conductive paste, the following was achieved:

- A 7 percent improvement in the average thermal resistance for the entire thermal pathway from the IGBT junctions to ambient

- An 11 percent improvement from case to ambient

| Table 2 – Performance of TIM compared to heat conductive paste | |||

|---|---|---|---|

| Thermal resistance, average over 9400 cycles |

Paste |

TIM |

Improvement |

| Junction to ambient (K/kW) | 114.75 |

106.66 |

7 % |

| Case to ambient (K/kW) |

73.92 |

65.93 |

11 % |

The improved performance stability of TIM, compared to heat conductive paste, is seen during the thermal cycling test (figure 3). The initial thermal conductivity of TIM is comparable to heat conductive paste. However, TIM layer suffers from less material loss after pump-out than heat conductive paste. TIM becomes viscous at temperatures above 45 °C. It spreads out during thermal cycling to provide a homogeneous coating at the base plate/heat sink interface, so it shows virtually no change in thermal resistance during power cycling. The thermal resistance of the heat conductive paste increases during power cycling, showing the degradation at the thermal interface. This does not occur with TIM, so using it provides improved reliability for the module during power cycling/operation.

About LoPak

LoPak are medium power IGBT modules (figure 4) which enable extra transient over-current capability by taking advantage of the IGBT module’s maximum operating junction temperature of 175 °C, compared to the typical 150 °C. The current configuration is a 1700 V phase-leg (half-bridge) IGBT module with copper base plate, using ABB’s uniquely designed SPT++ IGBT and diode devices and offered with 450 A, 300 A and 225 A current ratings.

This combination provides outstanding safe operating area (SOA) and over-temperature capability. Within its product class, LoPak benefits from ABB’s know-how in robust electrical performance and high reliability.

The detailed design and virtual prototyping used by ABB makes the LoPak module’s current distribution well-balanced during switching and especially controlled under overload conditions. Excellent field feedback has confirmed that the LoPak modules carries the same DNA for high reliability and robustness as the entire family of ABB’s high-power semiconductors.

The LoPak module is a key part in ABB’s expanding catalog of products to support the renewable energy and industrial marketplace.