William T. Lindstrom ABB Electrification, Smart Power Mephis, TN, United States, william.t.lindstrom@us.abb.com

In mid 2018, ABB acquired GE Industrial Solutions, GE’s global electrification solutions business. Since then, ABB has been busy integrating GE products into the ABB solution palette. One such integration combines GE’s Zenith ZTX and ZTG ATS series with ABB’s breakthrough TruONE™ technology to deliver an ATS that has improved system reliability, connectivity and ease of use. The new ATS series covers the ranges 30 to 1,200 A and 200 to 480 VAC.

ABB’s TruONE ATS technology

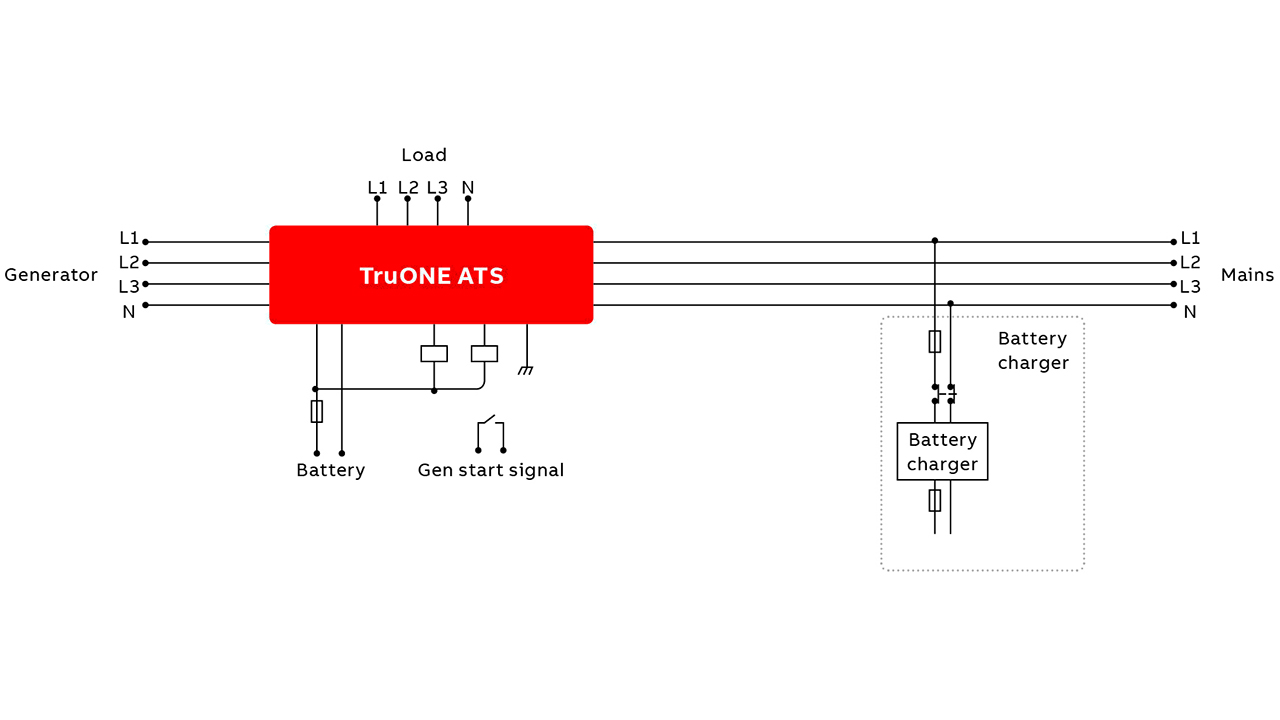

When a backup generator is utilized as an alternate source in a critical application – such as a data center, a health facility or transport infrastructure – an ATS starts the generator and switches the load over upon mains failure (and back to the mains supply when it returns).

For panel builders, installing a traditional ATS can be a complex task involving various sensors, controllers, switches and operator interfaces that all have to be configured and wired up. ABB’s TruONE ATS technology removes all this complexity as it requires just a single wire to be connected and uses standard enclosures.

TruONE is the first solution to package all the necessary sensors, controllers, switches and operator interfaces into a single, easy-to-install device that helps improve protection and makes installation simpler, more reliable and 80 percent faster →01–02. A modular design reduces downtime and service costs.

02a Traditional ATS installation approaches involve time-consuming and error-prone manual configuration.

02b TruONE has most of the ATS functionality needed in one package, this simplifying and speeding installation and increasing reliability.

02 TruONE’s architectural simplicity.

The Zenith ZTG and ZTX series

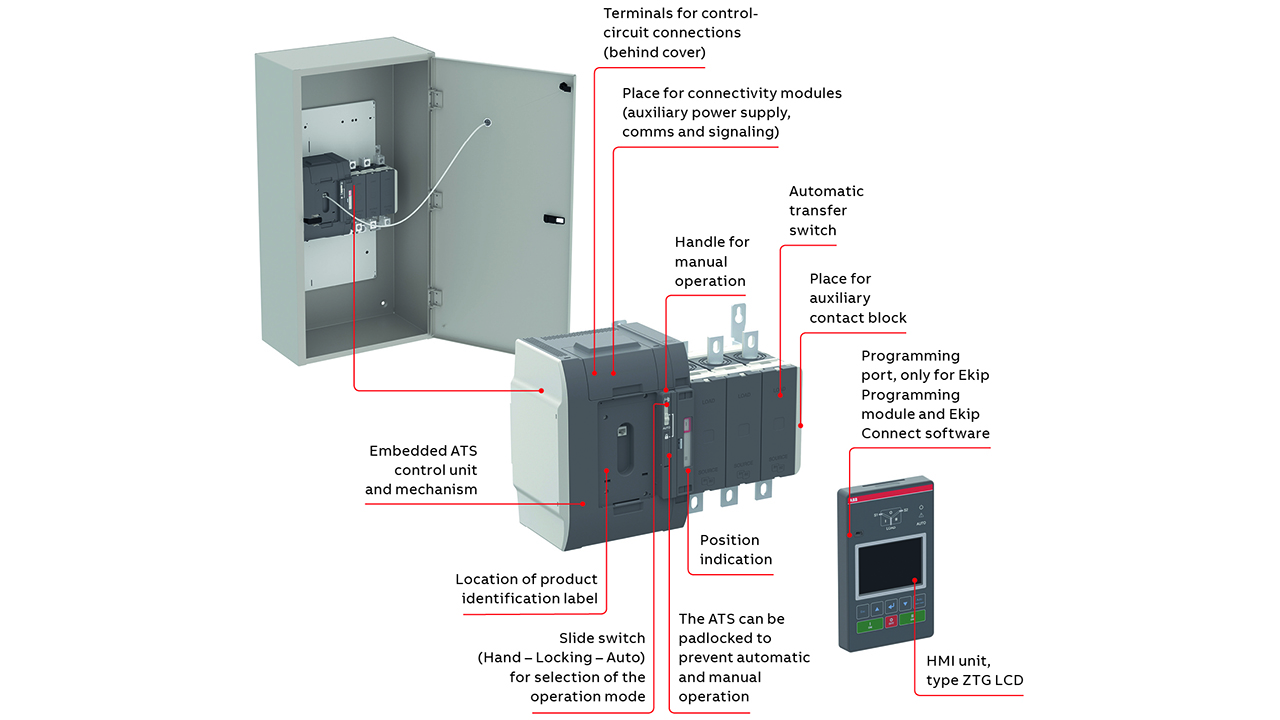

The Zenith ZTG and ZTX ATSs combine ABB’s TruONE with GE’s time-tested Zenith ATS family, which is renowned for its reliability and performance. The Zenith ATS thus incorporates both the switch and the controller in one seamless, self-contained unit within an enclosure →03–04. This reduces the number of wires and connections, provides up to 25 percent more space for wire bending in the enclosure and minimizes the potential for connection failures. The design also incorporates smart modular components that help reduce downtime and service costs by allowing controller and operating mechanism replacement in under 10 minutes.

The Zenith devices set new industry safety standards as the detachable human-machine interface (HMI) is completely electrically isolated – so potentially dangerous line voltages no longer need to be connected to the door →05. Further, IEC and UL test requirements are all met and/or surpassed by the Zenith.

The LCD HMI on the Zenith is password protected and allows access to features ranging from programmable set-points, time delays, digital I/O and access to switch status, event, and diagnostics information. For all models, ABB’s proprietary Ekip Connect computer software is an alternative to the HMI that enables remote as well as local programming. With this tool, ATS settings can be imported, exported, or modified via the USB port located on the HMI with no need to apply power to the unit. If multiple ATSs are on a network, Ekip Connect can be used to access all of the controllers, making commissioning and data access easy.

05a The HMI is plugged in via an Ethernet cable. This means the HMI is easy to replace, and in extreme circumstances, the ATS is fully capable of operating without an HMI.

05b The HMI is attached to the door exterior by two screws, with the HMI connector showing through and secured with a nut. An RJ45 cable connects the HMI to the TruONE unit.

05 The Zenith HMI.

One of the key inventions in the ATS design is the way it self-powers all the required functionalities via the mains connections (200 to 480 V AC, ±20 percent) without the need for any external voltage transformers.

Zenith ATS solutions are designed to last up to 6,000 cycles, which equates to 50 years of reliable operation, based on 10 transfers per month. All critical modules are customer-replaceable to simplify service and significantly reduce downtime and service costs.

The new device features a host of other design and engineering advances, including an ingenious contact construction that uses new materials and geometries to make load transfer more reliable.

Snap-on accessories for flexibility

Snap-on accessories – such as additional I/O, communication modules and terminal shrouds – can be added to the Zenith at any stage. These accessories lie within the device’s footprint and, as the name suggests, require no mounting tools.

Also, where auxiliary (position indication) mechanical contacts are needed in addition to the digital I/Os that are included as standard, they can also be simply snapped on without tools at any stage of the ATS solution creation. The same applies to the addition of different communication protocols (up to seven, see below), additional I/Os or a 24 V DC HMI auxiliary voltage supply.

Making the connection

An optimized interface makes advanced control, connectivity, and energy management much easier. With embedded connectivity, an auto-configure function and a range of programming options, setting-up with the Zenith ZTX and ZTG series takes a matter of minutes, as opposed to the potential hours of frustration that can occur with traditional ATSs. With no wiring, calibration, or troubleshooting work required, the new ZTX and ZTG are a big step forward in terms of expanding features and flexibility combined while improving ease of use.

With seven communications protocols providing all-round connectivity, the Zenith ATSs are part of the ABB Ability™ portfolio of solutions that boost customer productivity. Zenith has built-in condition monitoring and predictive maintenance functionality that ensures the device is available when it is needed.

To make system integration even easier, some Zenith models have the same user interface and software environment as the ABB Emax 2 smart air circuit breaker. Emax 2 enables a direct communication to the ABB’s energy management cloud-computing platform, ABB Ability Electrical Distribution Control System. Linking the Zenith ATS and ABB Ability Electrical Distribution Control System makes the ATS compatible with other ABB devices. Using a laptop with Ekip Connect Software, the Zenith ZTG can even be configured onsite before installation – without the need for an external power supply.

The Zenith is ideal for retrofitting old ATS equipment. The compact, lightweight (some 30 percent lighter than equivalent ATSs), and self-contained design along with the need for a maximum of only one control wire connection – ie, the Ethernet cable from the switch to the HMI should door-mounting be needed – makes replacement simple and quick.

As the power landscape continues its rapid evolution, the requirement for, and demands on, ATS equipment will continue to increase. ABB’s Zenith ZTX an ZTG will enable ATS operators to speed and simplify installation, improve reliability, lower costs, and improve power protection capabilities.

References

[1] R. Pelttari, “The power-of-one true ATS,” ABB Review 2/2018, pp. 90–93.