Designed to deliver further innovations in e-mobility, the state-of-the-art center will drive ABB’s R&D projects for electric vehicles (EVs).

Located on the TU Delft Campus, the complex, which will house up to 120 people, marks the return of ABB’s EV charging business to the home of its conception. The students who founded Epyon, the EV charging startup acquired by ABB in 2011, were from Delft University of Technology.

“ABB has led the way in EV charging and is proud to have played a key role in driving adoption rates across the world,” explains Frank Muehlon, Head of ABB’s global business for E-mobility Infrastructure Solutions. “That is why we wanted to locate our E-mobility Innovation Lab in Delft, in the heart of the university campus, where we are surrounded by the brightest tech talents and startups in the Netherlands.”

ABB Electrification invests approximately $400 million per year into R&D to remain at the forefront of technological leadership and set the standard when it comes to sustainable mobility. The research pushes the boundaries of e-mobility, predominantly in the areas of charging, storage and digitalization. The new lab will enable the company to strengthen its collaboration with EV manufacturers to drive further performance and progress across not only the booming electric car market but also for e-buses and e-trucks.

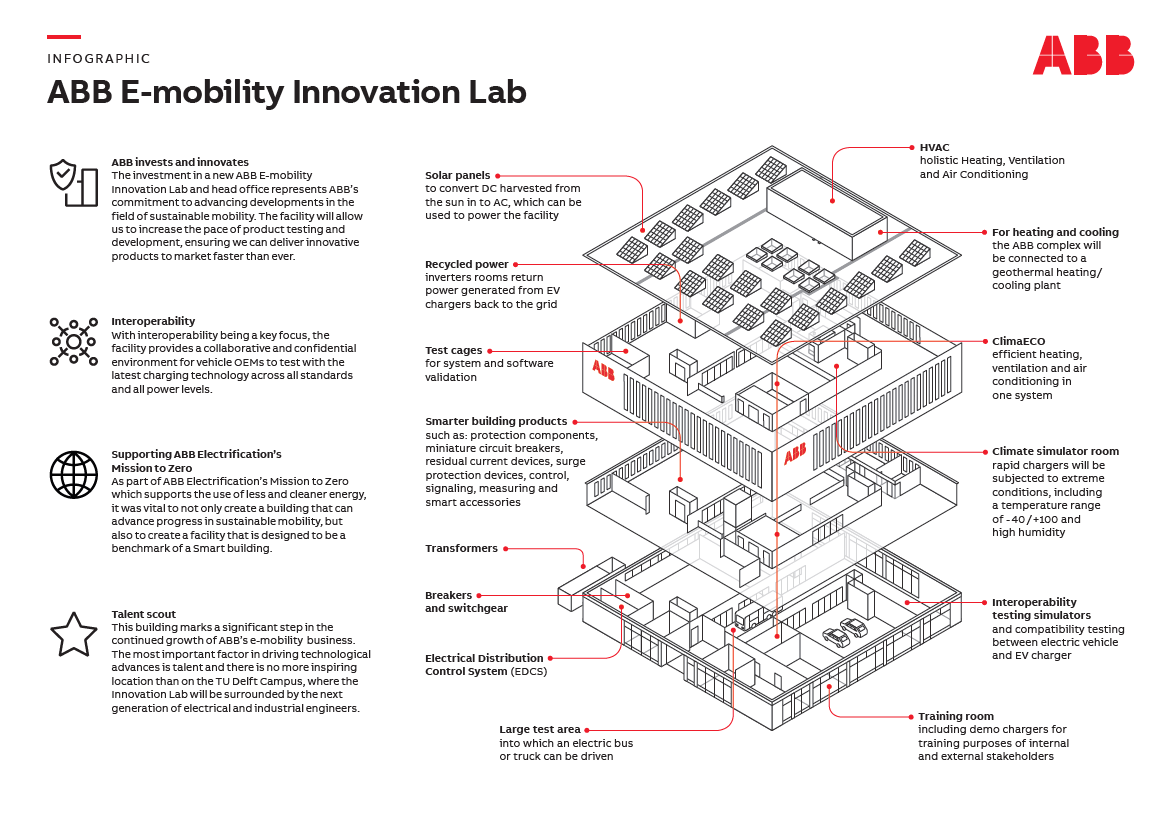

With interoperability the key focus for ABB chargers, the building has been fitted with the latest technology to ensure that ABB chargers are compatible with all types of vehicle. Due to the unique size of the lab’s open area the entire range of EVs are able to actually drive into the lab. Yet by creating a fully digitalized operation, not every vehicle needs to drive into the lab for testing. Almost 95 percent of all tests are conducted using a digital twin of the vehicles which are loaded into a simulator.

Experts from ABB and vehicle manufacturers will be collaborating together on the design and operability of the charging products. The testing will help identify areas for improvement, either in the vehicle or the charger, so solutions can be developed as a team.

Because of the critical need for charging equipment to work all the time in all conditions, a purpose-built climate chamber tests how vehicles perform in extreme temperatures. The charging solutions will be subjected to extreme conditions, including temperatures from -40 to +100 degrees Celsius and high humidity. “In the climate chamber we are actually challenging the equipment to the harshest conditions we can,” explains Andreas A. Mueller, Global Product Manager E-mobility Infrastructure at ABB.

As part of ABB’s commitment to sustainable development, the building is designed to be a benchmark of a smart building. For heating and cooling use, power comes from geothermal and solar energy, with excess electricity fed back into the grid. The overall energy efficiency of the building is improved through a range of ABB Smart Building technologies. "We see more and more fleets converting into electrical fleets – and seeing that, we see a higher need for electrification of whole sites. That really brings together much more than ever the automotive world and the electrical world – and ABB is positioned exactly at that interjunction,” shares Muehlon. “Our innovation lab in Delft will be key to drive all of that innovation, to push the boundaries, and to maximize the user experience for our customers and for the EV drivers."