Rajesh Ramachandran Process Automation and ABB Ability Bengaluru, India, rajesh.ramachandran@in.abb.com; Sohrab Bhot Process Automation Digital Mumbai, India, sohrab.bhot@in.abb.com

Is the world truly ready for the digital revolution? From a needs perspective – yes. Today’s industrial enterprise, whether in the process, energy or hybrid sector, is an asset-intensive producer – one that is highly complex with fast-moving processes and a myriad of input points; all with a high degree of interdependence.

In today’s highly competitive business environment industries search for every possible operational advantage to generate operational excellence →01, to enable them to produce the highest quality products, at the fastest rates, with the best and most reliable asset performance, cost-effectively. With production equipment pressed to maximum capacities, state-of-the-art industrial automation can be utilized to impose efficiency on the production process. By extracting value from a manifold of data generated by, and stored in, existing operational- (OT), engineering- (ET) and information technology (IT) systems, industries can achieve massive gains in productivity and make better business decisions. In this context, industrial enterprise management teams and operators alike acknowledge the power of digitalization to help achieve challenging outcome targets in today’s complex operational and business environment. And, yet, many companies struggle – not knowing where to begin their digitalization journey [1].

At the vanguard of digital innovation, ABB combines its vast industrial and automation experience with its capability to develop or utilize innovative digital technologies to help industries on their digitalization journey. In July 2020, ABB launched the ABB Ability™ Genix Analytics and AI Suite; this comprehensive and integrated enterprise grade digital transformation solution consists of a range of software, applications and services to help customers to improve productivity, process performance, product quality, efficiency and safety. In this way, ABB is poised to help customers successfully navigate digitalization.

Understanding the challenges

Given the high efficacy of employing digital technology – eg, 40 percent increase in productivity – it is surprising that enterprises are slow to digitalize. Currently, enterprises typically only exploit 30 percent of their generated data. This hesitation limits their ability to apply data analytics in a meaningful way and restricts their ability to harness potential business value [2,3]. Clearly, there is a gap between the acknowledgement of the efficacy of using digital technologies and being able, or willing, to harness the unimaginable value associated with digitalization [4]. By analyzing available trends, ABB investigated this conundrum and found that the root cause is not the lack of desire to digitalize but in knowing just where to begin. This is compounded by the scarcity of available and easy to implement market solutions, eg, requiring minimal change management; immediate in terms of results; customizable according to needs and preferences, and completely relevant in how impact is created.

As with any journey through uncertain and unchartered territory, insight leads to clarity and understanding. Clearly, the industrial world needs a quick, configurable, relevant solution, one that is high on impact and aligned with strategic business objectives. ABB’s digitalization concept crystallized out of this insight. This concept builds upon ABB’s common business ethos, namely, to address and alleviate customer's concerns over adopting digital technologies to ensure productivity gains. This conceptualized proposition takes into account the five “Ss”:

• Speed – rapid implementation; generating value in the shortest possible time

• Smartness – inherently intelligent with several pre-built features, driven by industrial domain knowledge

• Security – characterized by the highest standards of cyber security, thereby ensuring that customers are protected from exposure to cyberattacks and data privacy breaches

• Scalability – the ability to be implemented from edge to enterprise; and configurable based on context, requirements or preferences

• Simplicity – with complete ease-of-data integration, a high degree of interoperability, out-of-box integration, and easy-to-understand visualizations and applications

Digitalization – the path from idea to realization

Launched in June 2020, ABB Ability™ Genix is an enterprise-grade open architecture-based platform and suite that harnesses the power of industrial analytics and industrial AI to convert cross-functional data into actionable insights. The key lies in collecting, combining and contextualizing data from a multitude of sources across a diverse set of systems – OT (real-time data from operational technology), IT (functional data from information technology) and ET (design information from engineering) systems. For example, OT data from a critical asset, eg, a turbine, indicates how this asset is performing; the ET data indicates just how well or how poorly this turbine performs according to compliance specifications in regard to integrity and operational safety; and IT data indicates how to keep the asset performing at a desired condition with the right maintenance strategy, spare parts inventories, risk and investment planning, and more.

The ABB Ability™ Genix has evolved into a powerful platform, extending from the asset level through to asset ecosystems at plants and ultimately to the entire enterprise, covering all stakeholders, and yet critically, the basic unit remains the asset. Of course this includes the collation of the massive data that each asset generates. Since customers rely on assets designed and delivered by ABB eg, analyzers, instruments, drives, motors, generators, switchgear, propulsion systems and turbochargers, ABB is perfectly positioned to know how best to extract, converge, contextualize and utilize this data for prediction possibilities, flag improvement potential, and foster business opportunities.

However, this requires a new unified analytics model that relies on domain knowledge and AI. Historically, Original Equipment Manufacturers (OEMs) provided models for equipment based on physics, and, or, first principles, often referred to as digital twins.

Nonetheless, industrial manufacturing relies on a system of equipment or assets that all work in unison to complete a process. The effort of creating a first-principals-based model for such a complex system of assets would be prohibitive →02. The application of machine learning (ML) models, which are purely data driven, although quite promising, has drawbacks for industry. These models only provide insight about the conditions and anomalies for which the dataset has been trained. ML models have an inherently limited scope in an industry context because such situations have yet to occur. For this reason, ABB combines industrial domain knowledge with data driven AI/ML models to maximize algorithms for optimization.

Unleashing the power of data

Idolized in science fiction until as recently as three decades ago, the idea of autonomous manufacturing plants has been a dream for many. Recently, the rapid emergence of self-reporting and self-performing equipment have once again fired the imagination and this excitement permeates manufacturing enterprises worldwide as Industry 4.0 begins to unfold.

At first glance, Industry 4.0, is driven solely by automation. This perception is not entirely erroneous. Smart sensors and the Internet of Things (IoT) are among the most visible harbingers of this industrial transformation. And, automation, with ABB at the forefront, has a long history of bringing quality, accuracy and precision to industrial processes. But, automation does not propel digitalization, the scale and sheer ubiquity of automation does. Moreover, data plays the most decisive role – data from IT, OT, ET, and geospatial sources and others. The focus is on how to capture data, integrate it, contextualize it, store it and analyze it; and how to create insights from data that span functions and systems →03.

Managing the data value chain is key to achieving the five “Ss” of speed, smartness, security, scalability and simplicity – every element is dependent on the effective capture and treatment of data. The power of managing the smart data value chain is evident: Solution providers typically spend over 80 percent of their implementation effort on understanding industrial processes and data sources; and designing methods to capture data. But, this involves complex change management and implies a delayed return on investment (ROI) – invariably leading to company decisions to deploy only limited digital point solutions that will never match the impact of an enterprise-wide digital transformation. To achieve an enterprise-wide outcome, a seamless and secure edge computing integration is advantageous. Thus, ABB created the connection between the powerful industrial analytics and AI platform, ABB Ability™ Genix, and ABB Ability™ Edgenius, ABB’s operations data management tool. By offering this comprehensive integrated solution, ABB offers industrial enterprises a compelling argument to extend their digital transformation capability across the entire value chain; thus enabling strong outcomes on key indicators like operational excellence, asset integrity and performance, safety, supply chain optimization, energy efficiency and sustainability.

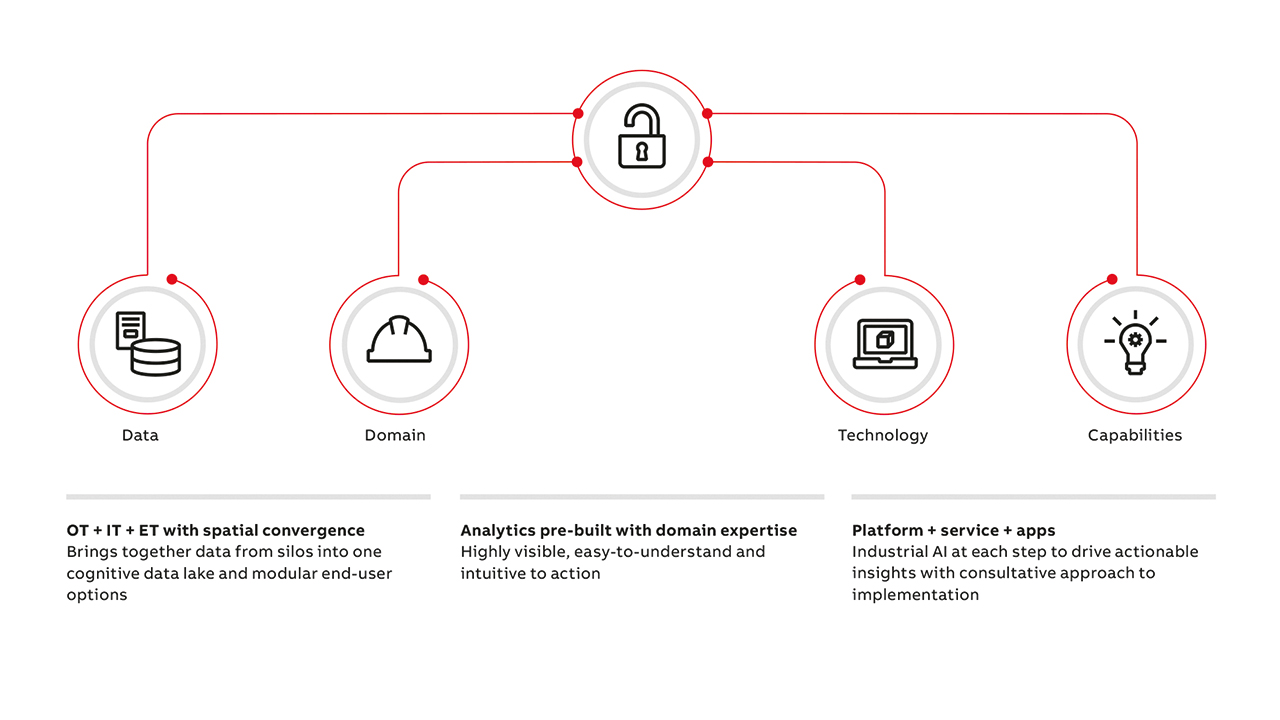

With data as the starting point of every element of the value chain, ABB Ability™ Genix and ABB Ability™ Edgenius uniquely combine ABB’s inherent strengths: domain knowledge, technology expertise and digital capabilities across the industries served. For ABB what really makes the difference in industrial analytics and the Industrial Internet of Things (IIoT) is the word “industrial”.

Unless digital technology is deeply integrated with operational processes, the path to Industry 4.0 adoption will languish and the value gained will be limited. At ABB, all expertise and industry-specific practical knowledge is therefore harnessed to create relevance in addition to transformation →04.

Achieving exceptional value – the ultimate result

At the end of their digitalization process, customers gain from a comprehensive solution; extensible from edge to enterprise; easily deployable on cloud, on premise or in a hybrid model. ABB has a solution in the ABB Process Automation asset and digital portfolio for every step customers choose to take on their digital transformation journey.

The first step is the introduction of smart equipment – assets that create digital footprints and data points. This step helps industries monitor asset health and performance, process, safety with real-time- or near-real time data. Only then can digital value-driver solutions be implemented.

Despite an understanding of the benefits of digital transformation, programs often run for multiple years and can be daunting. To alleviate apprehension, ABB created small pre-built analytics applications with clear value drivers for incremental benefits in mind. ABB’s digital portfolio combines data and domain expertise as the force behind applications to address five families of value drivers – operational performance management, asset integrity and performance management, safety, sustainability and supply chain optimization →04. Nonetheless, for full long-term benefits, such analytics applications must be built on a robust, scalable and modular platforms such as ABB Ability™ Genix. Some examples of pre-built analytics applications include: system anomaly detection, opportunity loss manager and heat exchanger fouling.

Additionally, the power of the ABB Ability™ Genix platform can be leveraged for rapid development of a specific analytics solution.

For example, a smart predictive maintenance solution collaboratively developed for ABB’s Azipod® gearless steerable propulsion system identifies potential anomalies and generates an early warning signal for maintenance teams – AI/ML-based models prevent failure. The engine for anomalous condition detection and early warning is based on the integration of real-time data of winding temperatures, speed, torque, power and inlet, outlet cooling air temperatures drawn from internal collaboration. Here, pilot implementation studies demonstrated an increase in lead time, of over one hour; this allows issues to be addressed before they potentially result into catastrophic failure.

Together, ABB Ability™ Genix, ABB Ability™ Edgenius with packaged analytical applications based on industry value drivers are heralding the way in which digital technologies, Industry 4.0 principles, industrial analytics and AI are shaping the future of industry.

References

[1] McKinsey & Company, “Unlocking Success in Digital Transformations”, in McKinsey & Company, Oct. 29, 2018, Available online: https://www.mckinsey.com/business-functions/organization/our-insights/unlocking-success-in-digital-transformations [Accessed June 7, 2021].

[2] Accenture, “Artificial Intelligence”, in Applied Intelligence website, in Accenture, Available online: https://www.accenture.com/in-en/insight-artificial-intelligence-future-growth

[3] M. Gualtieri, “Hadoop is Data’s Darling for a Reason”, in Forrester, Jan. 21, 2016, Available online: https://go.forrester.com/blogs/hadoop-is-datas-darling-for-a-reason/ [Accessed June 7, 2021].

[4] E. Charalambous, et al., “AI in production: A game changer for manufacturers with heavy assets”, in McKinsey & Company, March 7, 2019, Available online: https://www.mckinsey.com/business-functions/mckinsey-analytics/our-insights/ai-in-production-a-game-changer-for-manufacturers-with-heavy-assets [Accessed June 7, 2021].