Greg Parsons ABB Process Industries, Process Automation San Diego, CA, United States, greg.parsons@us.abb.com

In the parts service sector, too many companies still rely on a reactive parts management strategy in which parts wear down and eventually fail; this can cost up to five times more than using a proactive approach [1]. ABB grasps that digitization can foster a customer’s ability to take proactive control of their spare parts management to reduce the risk of unplanned costs, poor performance and downtime associated with perfunctory reactive parts management [2]. After all, why wait until a crucial part fails to replace it? And, why not utilize the technical capabilities emerging from digitization to empower customers to seize control of their part management?

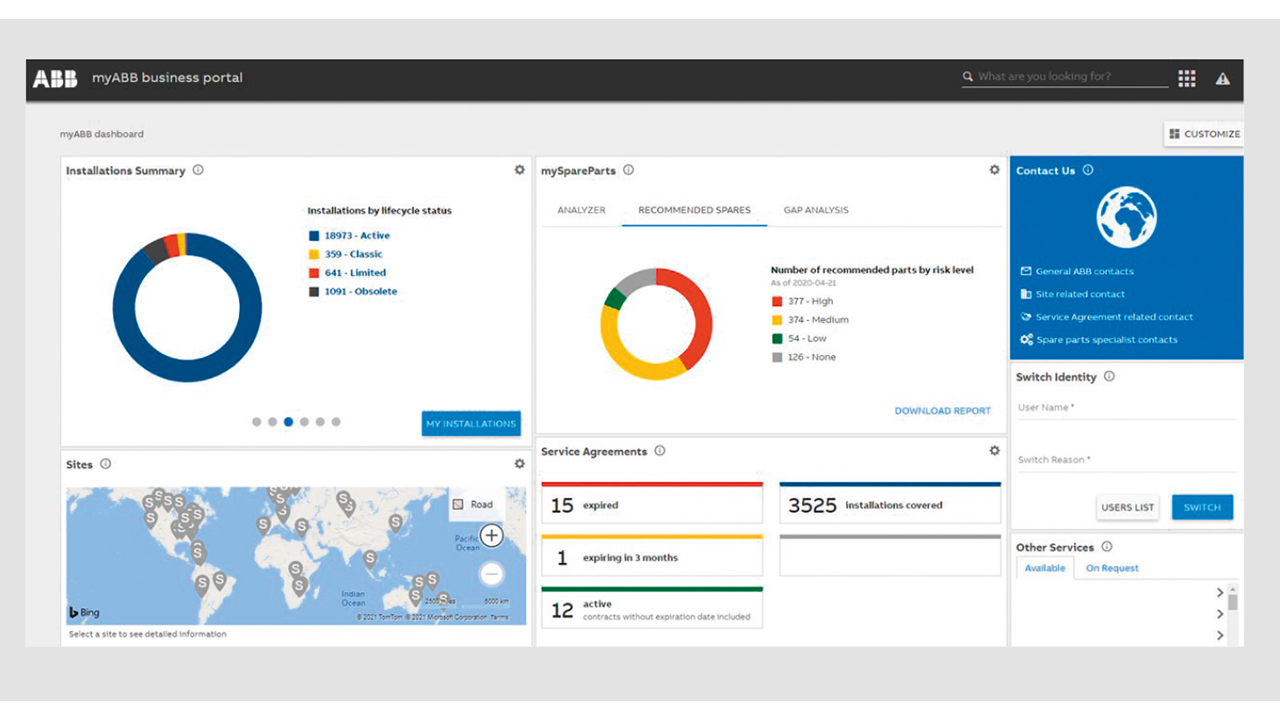

Now, customers can access a set of self-service digital tools for control systems, robots, drives and other ABB products through system-specific applications and widgets on myABB business portal. In 2020, ABB added parts to this product lineup by introducing the mySpareParts widget. This self-service process enables customers to scrutinize their site inventory through the mySpareParts Analyzer, compare this with their installed base in mySpareParts Manager and with what is available in the global ABB supply chain.

Recognizing the challenges

Frequently, companies mistakenly consider parts separate from the system in which they operate [1]. The reality is that with ever evolving and changing technologies, parts management requires both a systematic approach and systemic understanding. Only then can companies adequately evaluate and assess the criticality of parts in the system. Moreover, not all parts are created equal – some are more critical than others. Malfunction of some parts might pose a safety risk and result in a shut down, others might simply reduce the production speed, while others might adversely affect system performance. Consequently, intrinsic risk must be defined [1]. To have the optimum level of critical spare parts available, customers require a “birds eye view” of their asset and spares ecosystem. By knowing which parts are installed in their system, customers could fully assess and understand the criticality and interdependency of each part in the system and the impact of a failed individual part on the system and its performance. Nevertheless, such a strategic approach to parts management is a balancing act; establishing the comparative importance of parts and analyzing the likelihood of failure or disruption is challenging.

The current state of affairs

By basing decisions predominantly on the cost of parts or their historical usage, many companies underestimate their critical spare part stock by up to 60 percent [3]. The potential cost or financial implications of asset failure, production downtime or reputation damage from an interruption to “normal service” are not considered. This reactive approach to parts management can also have unexpected consequences due to potential supply chain unpredictability. Typically, when the author of this article asks customers about spares, the common response is, “we’re good on parts” and the author’s reply is how do you know? Many find it challenging to answer that question because there has to be some documentation of the process, in order to reach that conclusion. In practicality what we find is that there are gaps that ABB can address. There are even cases where the customer does have everything that they need which carries validation within itself that they are doing everything correctly today. However, this is not a static process, lifecycles and support structures change. This needs to be evaluated on a regular basis.

The failure to plan nurtures a potential for waste of manpower, materials and machine time; and this raises the manufacturers‘ costs and ultimately the price of a product.

ABB’s mySpareParts management solution

The solution to such challenges lies with a comprehensive proactive yet tailored digital parts management approach. With a detailed inventory of the installed-base on-site captured, companies could better define their parts strategy and enact it. Customers also gain from measuring spares holdings value against the cost of potential downtime, suboptimal performance and loss of reputation if customer commitments cannot be met. By evaluating the system under normal operating conditions, customers can understand the supply chain – before costly problems occur. Clearly, a holistic parts management program must understand what will happen when a part fails – before it fails.

Enter ABB’s mySpareParts Manager, a proprietary software platform, designed to generate the customized recommended parts, gap, and supply chain information, along with reports for the identification of risk. This is accomplished by examining important information including:

• Current install base

• Item to part associations

• Site Inventory

• Product lifecycle

• Site parts product and location information

• Parts risk level

mySpareParts widget

The widget gives customers a “birds eye view” of the data needed to make proactive decisions to ensure production availability and prevent or reduce stock-related disruptions. The widget, mySpareParts, is a centralized platform that currently has three views: mySpareParts Analyzer, Recommended Spares and Gap Analysis →01.

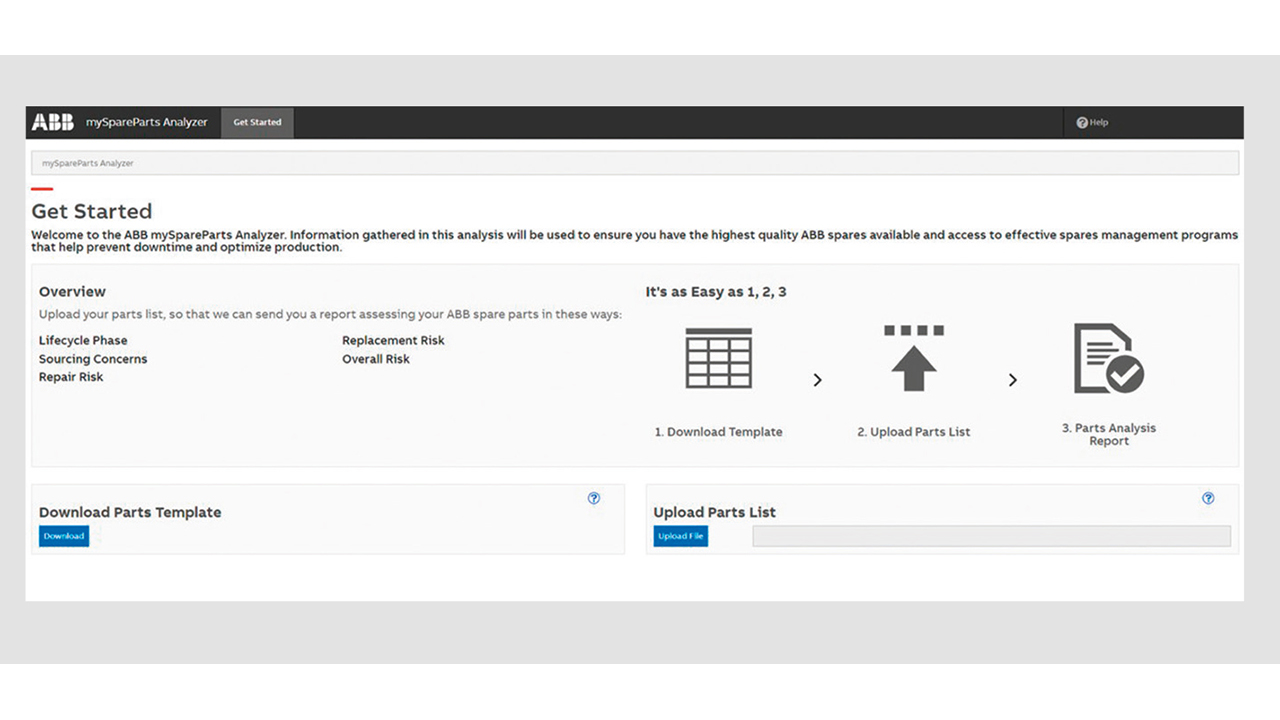

mySpareParts Analyzer is a self-service tool that allows customers to upload their existing spare parts inventory and allows ABB to analyze and report to customers →02. Customers gain insights into risk factors →03, lifecycle status and replacement options based on country stock and replaceability, and repairability. A core element of the risk analysis is evaluation of the risk of failure →03. This product takes into account the “intrinsic risk” of each item in a customer’s installation. To accomplish this ABB has built a library of risk for over 1.5 million parts using an internally developed proprietary Bayesian model.

ABB’s mySpareParts Analyzer, thus, helps companies identify gaps in spare parts inventory to prevent downtime, optimize production, and facilitate strategic thinking around their existing spares inventories.

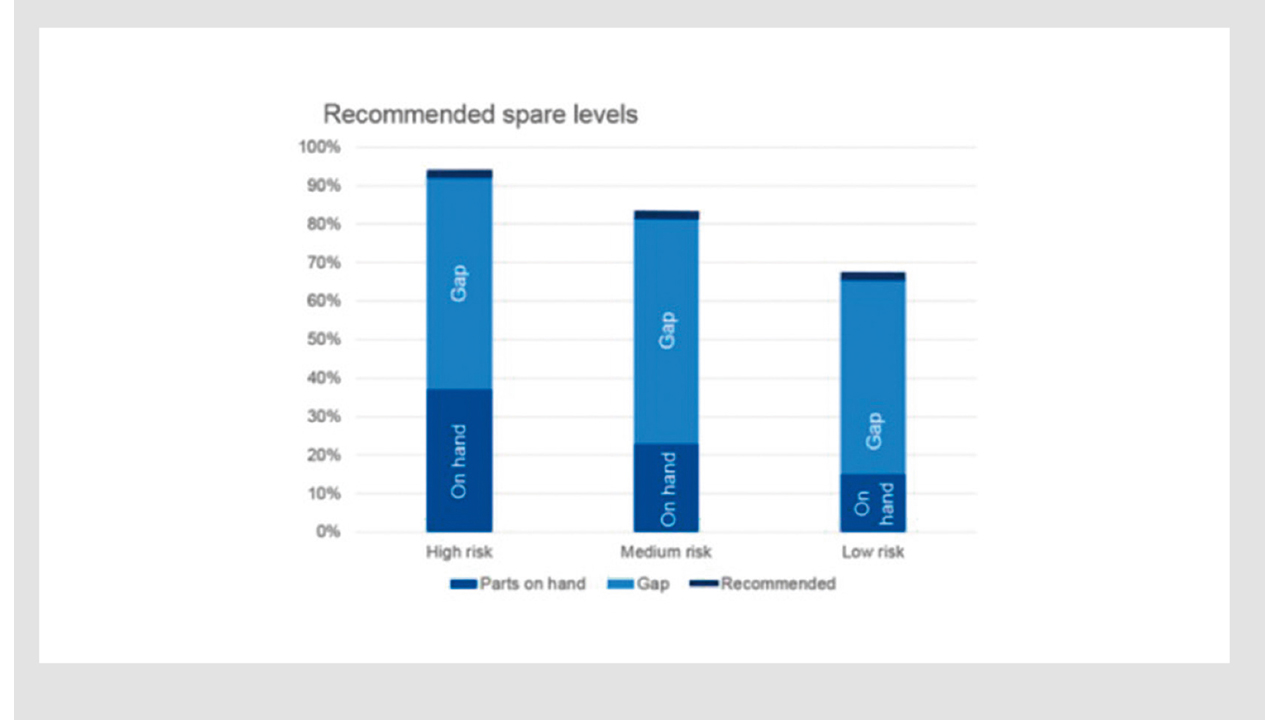

Inputs from the mySpareParts Analyzer tool and ABB’s ServIS install base management tool are combined in the mySpareParts Manager. Customers are provided with two additional views: Recommended Spares and Gap Analysis →01. With Recommended Spares, the customer sees a list of items that ABB recommends to stock based on the customer’s site-specific install base and includes important data such as part inventory risk to process as well as lifecycle. Gap Analysis combines the Recommended Spares information with the Analyzer Spare information and proactively searches for missing and excess inventory items. The user can filter information at will. For instance, a customer can filter only those items that are classified as high risk with late life cycle statuses. The customer sees how many of these parts ABB recommends to stock. These reports are delivered in a document called a Parts Fingerprint.

Collaboration for a tailored solution

ABB works together with the customer and the ABB MySpareParts Manager tool to edit all the site-specific information to identify a path forward. The complexity surrounding spare parts does not stop once the optimal spare part holding has been identified. It is essential that a robust and effective inventory management solution is in place to protect these assets. ABB can tailor a spare parts inventory management solution to suit a customer’s specific goals, maintenance strategies and operational needs; this ensures critical operational spares will be immediately available where and when they are needed. While ABB’s primary option is to always provide spares directly to the customer, occasionally a vendor-managed spare parts inventory system may be included in an ABB Service Care Agreement.

Taking analysis one step further

ABB Parts Fingerprint solution is an in-depth systematic process designed to provide customers with a spare holding recommendation for the purpose of arriving at an agreed optimal spares holding. Informed and defined by the customers installed base, risk of part failure to the process at an individual part level, the environment within which the part is operated and the supply chain, this solution allows ABB to share information on customer spare parts; thereby enabling customers to take control of their spare parts strategy and management.

With expertise and understanding of their own parts and equipment, ABB relies on an iterative three stage process to address evolving life cycles and obsolescence: assess, implement and sustain. Outputs include reports for Recommended Spares, Spares Gap Analysis and Supply Chain Analysis. The process captures detailed equipment configurations down to the part number level. It includes an audit of the existing parts held by the customer and captures quantity and quality information to facilitate improvement recommendations. It also promotes analysis of the supply chain and identifies parts issues proactively →04.

Parts Fingerprint case studies

ABB managers of a chemical company in Louisiana, USA recognized that to ensure maximum production, they needed optimum availability of their existing control system. They needed to know if gaps existed between critical high-risk spares that might be needed and their actual on-site availability. →03. Based on the Parts Fingerprint from ABB’s ServicePro Service Management System, ABB helped this customer to understand their parts situation and to decide whether to upgrade their control system, thereby ensuring high production availability. As part of the IAEN Service Account Management initiative, in 2020, ABB Malaysia executed an end-to-end Parts Fingerprint process for a customer →05. Starting with the data collected from the SPDC scan of the ABB’s 800xA Power Management System and combining that with the information shared by the customer through the Parts Analyzer. The Parts Fingerprint report showed the installed components- and recommended spare parts quantity, matched the recommendation with the customer inventory gathered from the Parts Analyzer, and highlighted the gaps between recommended parts and actual stock. After a common evaluation of the Parts Fingerprint report, the customer proceeded to supplement the existing stock with the agreed items identified to represent a potential operational risk.

A view to the future

An additional Supply Analysis report view is scheduled for release in 2021. Here, the gaps identified are compared with the supply chain – against the local, regional and main stocking centers – to develop a customized stocking plan. Additionally. a more in-depth analysis of a customer’s order history, recent failures, etc. will be possible.

With mySpareParts management solution, customers get the data they need – including elements like intrinsic risk, main regional and local stocking plans, lifecycle impact on products and parts, all compared to the products and services for their needs throughout the lifecycle of their plant and product. Moreover, customers understand what is recommended, combined with their current situation, in order to form a plan of action – this facilitates decision making. With the analytical power of ABB’s digital toolset, customers are empowered by this proactive approach to systems and parts management to mitigate risks.

References

[1] Marshall Institute website: [Online] Available: https://www.marshallinstitute.com/[Accessed July 6, 2021].

[2] J. Bughin et al., “Why Digital Strategies Fail” in McKinsey Quarterly, Jan. 25 2018, Available: https://www.mckinsey.com/business-functions/mckinsey-digital/our-insights/why-digital-strategies-fail [Accessed July 5, 2021].

[3] GrowthPoint Marketing website: [Online] https://growthpoint-inc.com/ [Accessed July 5, 2021].