Guangdong MOOC Technology, with headquarters in Foshan, Guangdong province in China, is a leading machine builder that produces furniture component sanding machines. Their machinery is relied upon for precision automated sanding tasks by furniture and home furnishing component manufacturers throughout China and South-East Asia. This includes sanding and polishing of wood furniture parts, such as modular kitchen cabinets and doors, before they are assembled as the complete furniture.

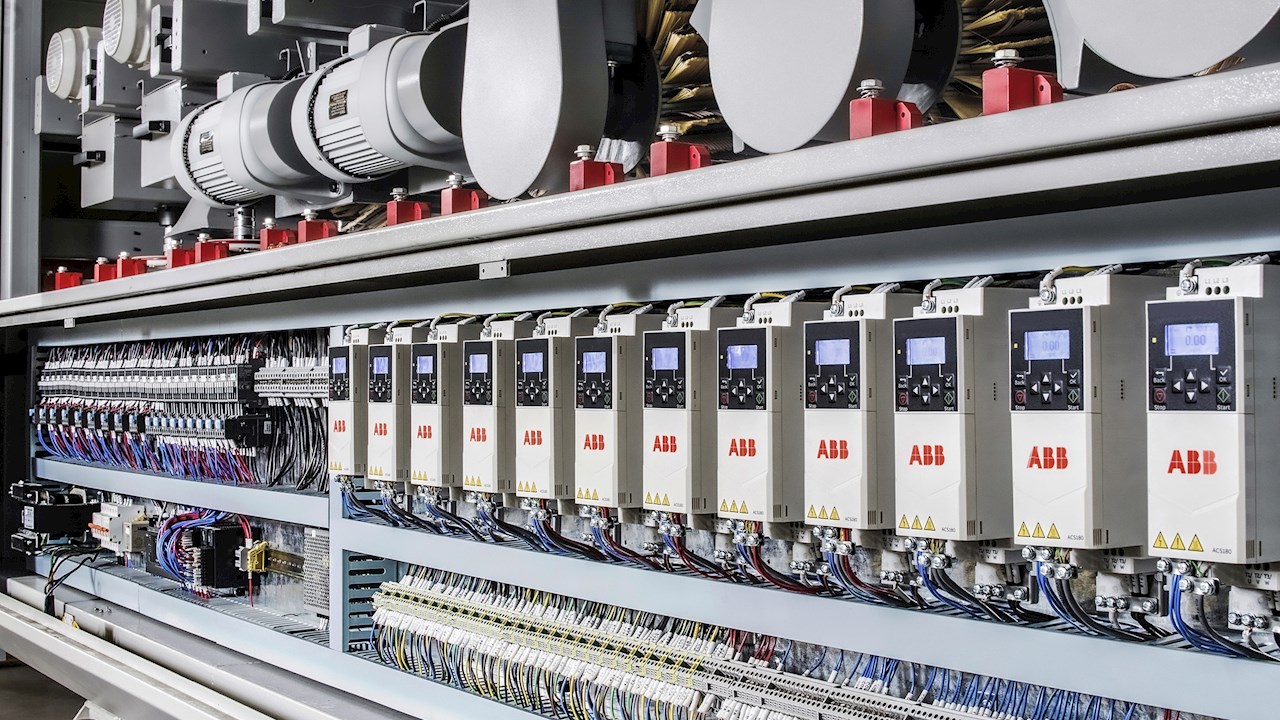

The sanding machine usually consists of a conveyor belt where the coarse, unfinished wooden or composite parts are fed in at one end and then come out with a finely sanded, polished surface at the outlet. A typical sander uses two motors at 2.2 kW per motor for moving the conveyor. The surface sanding is accomplished by means of 10 sanding/polishing drums in the machine that progressively smooth out the material’s surface as the furniture parts move forward in the conveyor. There are 10 pcs of 1.5 kW motors providing rotational force to these drums, with the speed and torque of the motors closely controlled by ABB’s compact ACS180 variable speed drives (VSD).

Impact overload was previously a challenge

Before adopting the ACS180 drive in the sanding machines, MOOC had earlier faced a problem where the load suddenly fluctuated on a motor. The previous VSD controlling the motor was not able to compensate for these load changes, causing the VSD to fault.

Because the previous VSD did not have sensorless vector control, the motor speed could drop significantly and become overloaded. This led not just to uneven sanding and poor surfaces on the furniture components but even tripping of the VSD, causing the machine to stop and upsetting the workflows.

Confidence and peace of mind that the machines will work well

Attempting to solve this problem – and give both MOOC and their customers that use the sanding machines peace of mind – MOOC decide to try ABB’s compact ACS180 machinery drive that is specifically optimized for this type of application.

One of the key features in the ACS180 machinery drive is the built-in sensorless vector control that makes the sanding process more accurate and also eliminates any risk of tripping the machine. This gives confidence to both MOOC and its customers that the unit will deliver good productivity and high quality pieces.

Small size, for a perfect fit

Furthermore, due to the compact size of the ACS180 VSD it could easily fit into the cabinet in the polishing machine where the previous VSD was situated before. This meant that MOOC saved time and money since no redesigning was required to fit the ACS180 in their machine. In addition, other useful features included as standard in the drive – like built-in Modbus connectivity and integrated functional safety, Safe Torque Off (STO) – have been helpful for both machine design and machine building.

Pleased with the change

Mr. Guiquan Yang, General Manager of Guangdong MOOC Technology, explains how the device has helped them. “Before we began using the ACS180, there was a risk of overload in the machines,” he says, “and this led to abnormal polishing speeds and sometimes even unexpected shutdown. Therefore, we were looking for a drives manufacturer that could provide a drive to help improve operational reliability and user friendliness, while also supporting with good local services when necessary.”

“Since changing to the ACS180 we have seen that it has excellent performance, with high torque reliability and strong overload capacity. This makes the polishing process more accurate and reduces the unexpected failure rate of the machines. Furthermore, the ABB brand reputation and the compact size of the ACS180 are also adding highlights to our sanding machine.”

The ACS180 is very user friendly, and commissioning is done via the control panel that can be held in one hand. Its easy-to-install and easy-to-use features greatly reduce the workload on the customer's technical engineering team. And, in case of any need, ABB’s experts and channel partners are ready to provide support at any time. Finally, the competitive price level of the ACS180 offers excellent value to both MOOC and its customers.

To find out more please visit the ACS180 website.