Embarking on an ambitious project like Mission to Zero might seem overwhelming, especially for smaller companies with limited resources.

Ali el-Abbassi, Local Product Group Manager at ABB Electrification’s Smart Buildings facility in Ede, the Netherlands, has two simple but powerful words of advice: “Just start.”

The journey to net zero begins not with massive investment, el-Abbassi said, but with a mindset shift.

“Over-planning can paralyze teams and stand in the way of progress,” he continued, stressing the importance of incremental action and flexibility. “Once you have data and discuss it with your team, the way will appear.”

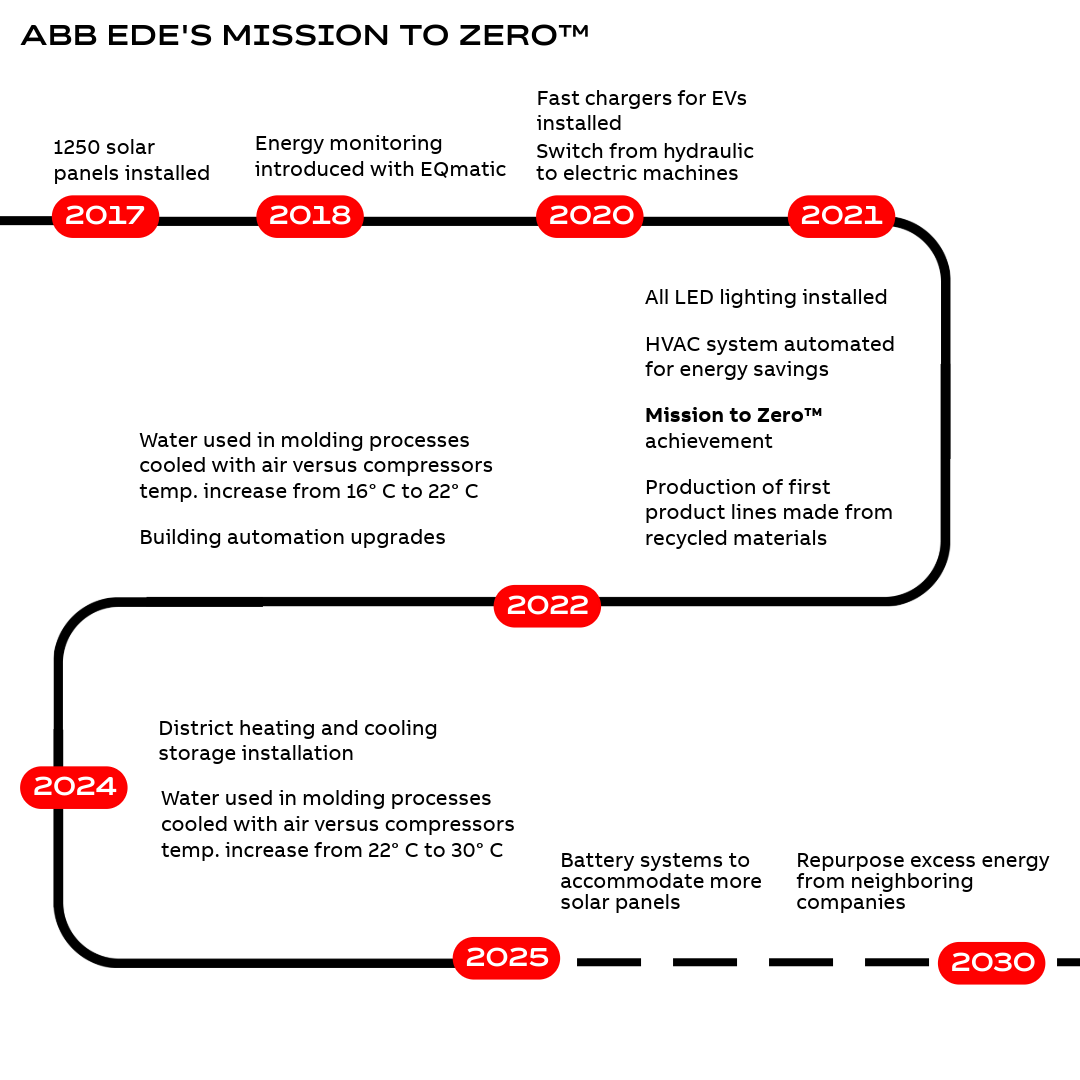

When Ede embarked on its journey to Mission to Zero in 2022, el-Abbassi and his team had a strong head start. By then, the factory, which produces junction boxes and energy distribution enclosures, had already built a strong track record of sustainable manufacturing. It had fully electrified hydraulic molding machinery, converted to all-LED lighting, and installed 1,250 rooftop solar panels to power its operations.

“Ede has always been motivated by sustainability,” said Ali el-Abbassi. “It’s both part of our culture and a day-in, day-out passion. With Mission to Zero, we wanted to get the entire unit onboard and build awareness to help us achieve our goals. The timing was perfect.”

Achieving Mission to Zero through a combination of smart building solutions, renewable energy, and ABB tools and technologies further fueled the team’s passion. It served as a springboard for continuous improvement and innovation. Ongoing efforts include deeper automation to improve energy efficiency, incorporating recycled materials into product development, eliminating manufacturing waste, and reducing emissions by optimizing delivery routes.

“There is no finish line,” el-Abbassi said. “Mission to Zero is motivation to keep going. This is just the beginning as we expand the boundaries of our sustainability goals and encourage others to do the same.”

A measured approach

Ede is a real-life case study in the power of collaboration to drive change. From daily department-level check-ins to cross-functional collaboration, environmental responsibility is woven into the team’s rhythms, routines, and decision-making.

“Sustainability is not just about technology,” el-Abbassi said. “It starts with our attitude, behavior, and other human elements.”

This collective commitment powered the team’s path from day one. A multi-disciplinary task force created a roadmap using ABB’s Energy Asset Manager to baseline the factory’s energy consumption. “It was a real eye-opener,” said Rene Wienholts, Innovation and Technology Manager. “Before, we had very little visibility into how much energy specific machines were using.”

Patterns emerged: energy use spiked when machinery restarted on Monday mornings after a weekend off, for example. These insights led to practical changes, including better load balancing and deploying ABB smart building technologies to automate lighting, heating and cooling.

Smart sensors now shut down lights in unoccupied rooms. A recently installed underground heating and cooling storage system leverages seasonal shifts to maintain optimal temperatures without compressors. Warm air is stored underground in the summer and heats the factory during colder months, and vice versa.

Balancing input and output

With electricity demand and grid congestion growing nationwide, the Ede plant is focused on powering operations in the most effective and efficient ways possible. “We have to be hyper-aware of our usage, down to every kilowatt,” Wienholts explained. “Electrification and energy reduction must go hand-in-hand. The more we dig in, the more we discover we can still do more.”

The team has taken creative steps to balance both sides of the energy equation. The site uses solar during peak daylight, when others are drawing more from the grid, and only uses surplus electricity from the grid at night, when demand is lower. Systems that take more power are run at night, rather than during the day, to reduce energy usage. A local transport company that delivers products to customers, for example, charges their electric truck on-campus overnight using ABB fast chargers.

Sharing the journey - and the lessons

From day one, the team shared its plans with local government officials, neighboring companies, and other community stakeholders. “We committed to updating them on our progress and making our learnings accessible to all, because we see this both a shared responsibility and a collaborative learning journey,” Wienholts said. “The more we share, the more we all gain.”

Ede has become a showcase of energy-conscious innovation. Journalists, customers, suppliers, and local stakeholders tour the facility to see first-hand how digital tools can decarbonize manufacturing operations. The team’s willingness to share – and learn – has created a positive ripple effect.

A longstanding logistics partner, for example, was inspired to purchase an electric delivery vehicle it now charges using ABB technology. Even coffee became a catalyst for change: teh site relaced its global vendor with a local supplier on a similar Mission to Zero journey. “If we’re on the same path, it makes sense to support each other,” el-Abbassi said.

This is the second story in a series about progress made at our first Mission to Zero™ sites around the world. The first site featured was our Porvoo, Finland facility. Mission to Zero is our journey to reach net-zero emissions and more sustainable operations. Bringing together technologies using ABB digital solutions and renewable energy, we’re increasing efficiency and reducing emissions at our sites. To learn more, visit our webpage.