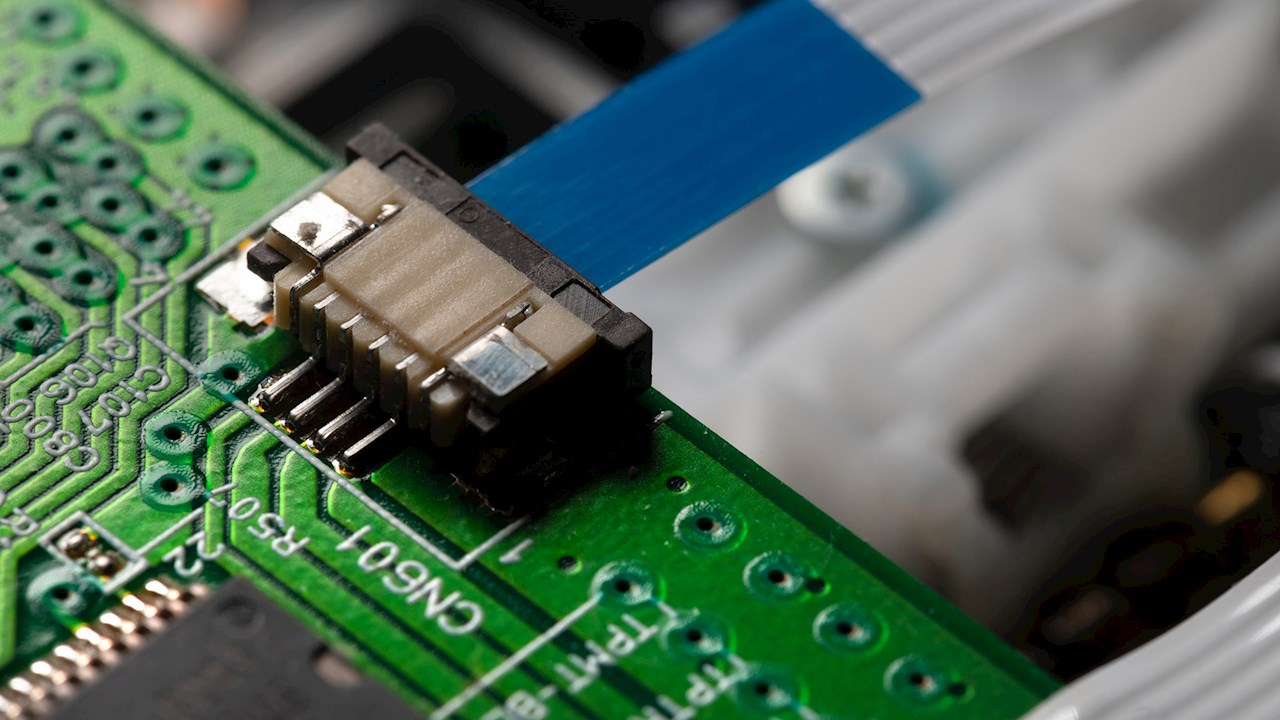

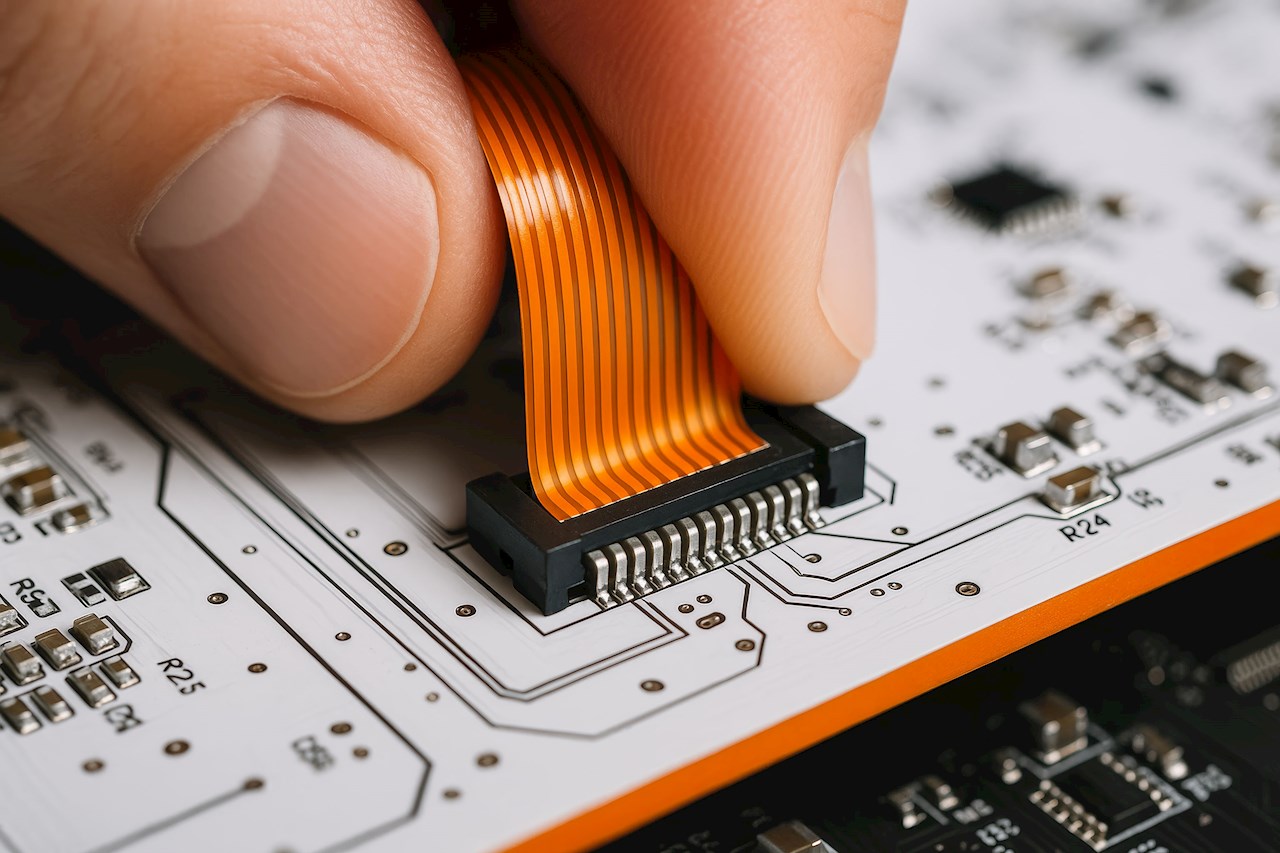

As a vital component of electronics used in everything from smartphones to electric vehicles, flexible printed circuits (FPCs) require precise and consistent assembly to ensure they achieve the required quality.

For manufacturers, a common challenge when automating their production processes is being able to handle the wide variety of cable types and connector geometries without impacting on yield, changeover speed and return on investment.

The solution: The combination of ABB robots together with, force control and modular design

ABB’s GoFa™ cobots and IRB 1100 robots are helping to provide manufacturers with a solution to this challenge by enabling fully automated FPC cable insertion and locking. Equipped with integrated vision and force control technologies, these robots are ideally suited to delicate production operations by ensuring accurate component placement and real-time quality verification.

In this application, the robot handles the task of positioning and inserting the flexible cable into the board-mounted connector. Using force control, it detects resistance and dynamically adjusts its motion to avoid damaging the connector or pins. By combining force sensing with smart vision, each insertion is perfectly aligned within the required tolerances.

Built around ABB’s OmniVance modular platform, the automated assembly stage can be readily adapted to a wide variety of cable types. Users have a choice of three modular options, including a robot module integrated with vision and force control functions, a conveyor system module, and functional modules for pre-positioning and location, with the added ability to select different gripper options to suit specific cable sizes and configurations.

With ABB’s RobotStudio® software, users can also develop, simulate and test changes offline, enabling faster deployment and smoother transitions between product variants.

The outcome: Precision assembly with high yield and process flexibility

Preliminary testing has demonstrated that the system can accommodate an alignment margin of ±0.25 mm per side, with a maximum allowable deviation of ±0.4 mm between connector center and pin center. This tolerance, combined with the responsiveness of the force module and the accurate inspection provided by the vision system, ensures reliable and consistent performance, minimizing the risk of production errors.

By applying a standardized solution across their applications, manufacturers are achieving consistent performance and faster cycle times. With a target cycle time of 28 seconds, the setup delivers on the dual goals of speed and accuracy. The combination of force control and vision ensures 98 percent yield rates while providing a clear quality check for every cycle.

The modular design supports quick changeovers with minimal disruption. When switching between different cable types or board designs, operators simply replace the relevant gripper or alignment fixture. The entire process remains consistent, with RobotStudio ensuring that new parameters can be validated in a virtual environment before going live.

Why it matters

As the electronics industry continues to embrace miniaturization and higher connection densities, the need for fast, high-accuracy assembly processes is growing. Manual methods struggle to keep up with the yield requirements and quality standards expected in applications like electric vehicle battery connectors, wearable devices or medical electronics.

With ABB’s robotic solution, manufacturers can achieve the best of both worlds – the precision of advanced automation and the flexibility demanded by high-mix production environments. The result is a cable assembly process that not only meets performance goals but is also scalable, maintainable and ready for the challenges of tomorrow’s products.

Discover more about GoFa and IRB 1100

Contact us for more information