Ravago Lavrion is the Greek production plant of Ravago Hellas, which specializes in Building Insulation materials (XPS). It joined the Ravago Group as part of a broader European asset acquisition from Dow in 2018 and is the only Ravago plant in Europe producing raw Polystyrene in continuous, uninterrupted mode supporting local market and other European XPS plants.

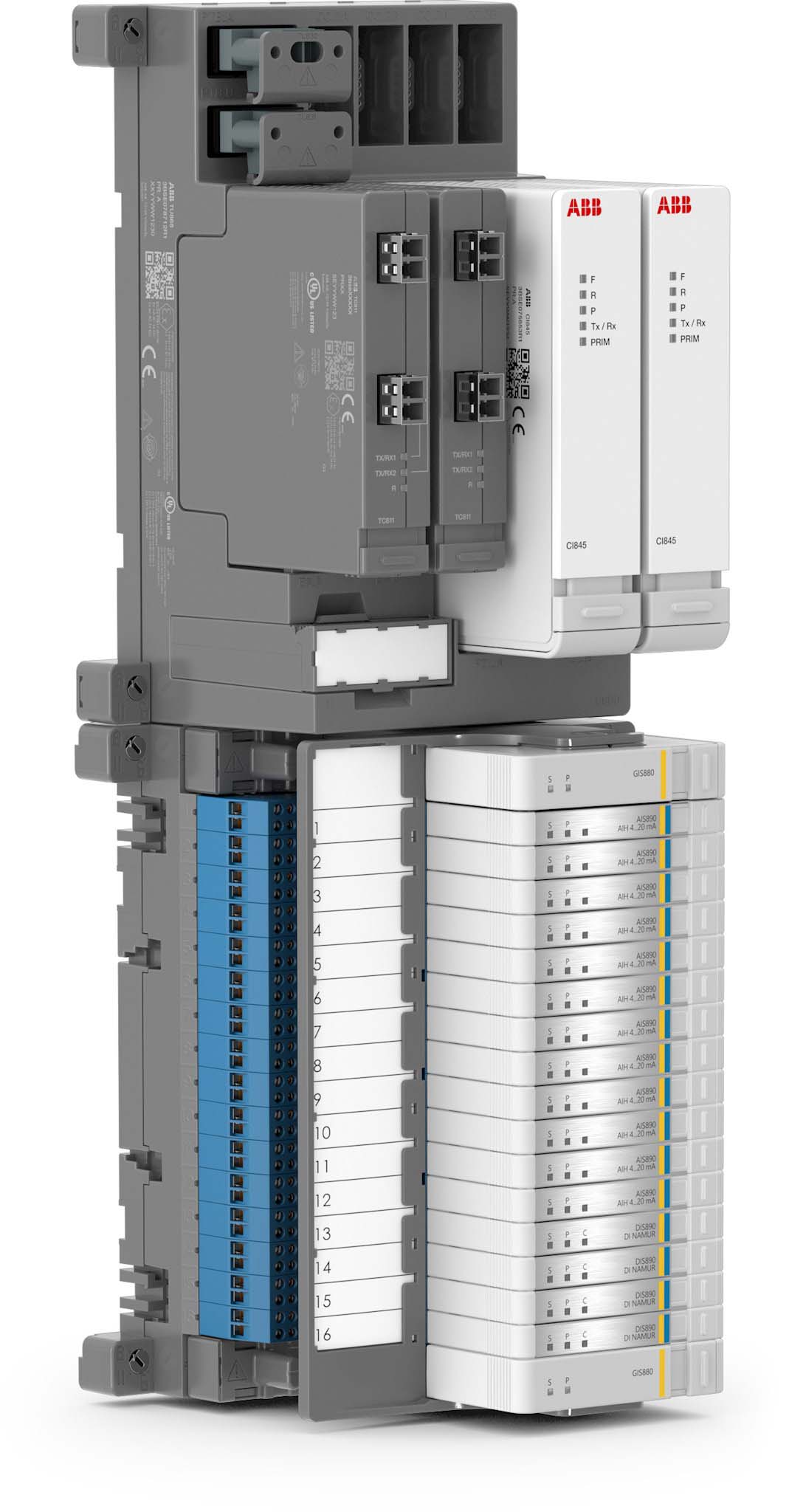

Recently, the Lavrion plant commissioned its new ABB Ability™ System 800xA® DCS in a smooth migration from the legacy MOD5 Process Control System, which had reached its end-of-life and required replacement. Ravago sought a modern, future-proof system that could be implemented in a manner that would safeguard continuous operation of its high-value PS production line. It was also looking to get the best possibilities for enabling digital transformation, as well as the highest protection against cyber risks.

Following technical assessment discussions, ABB was selected to supply the equipment and undertake the seamless DCS transition. The aim was to give Ravago the latest technology platform that would be capable of supporting critical production tasks and ensuring full regulatory compliance, with absolute minimal operational disturbance.

Seamless project delivery with ABB’s Adaptive Execution™

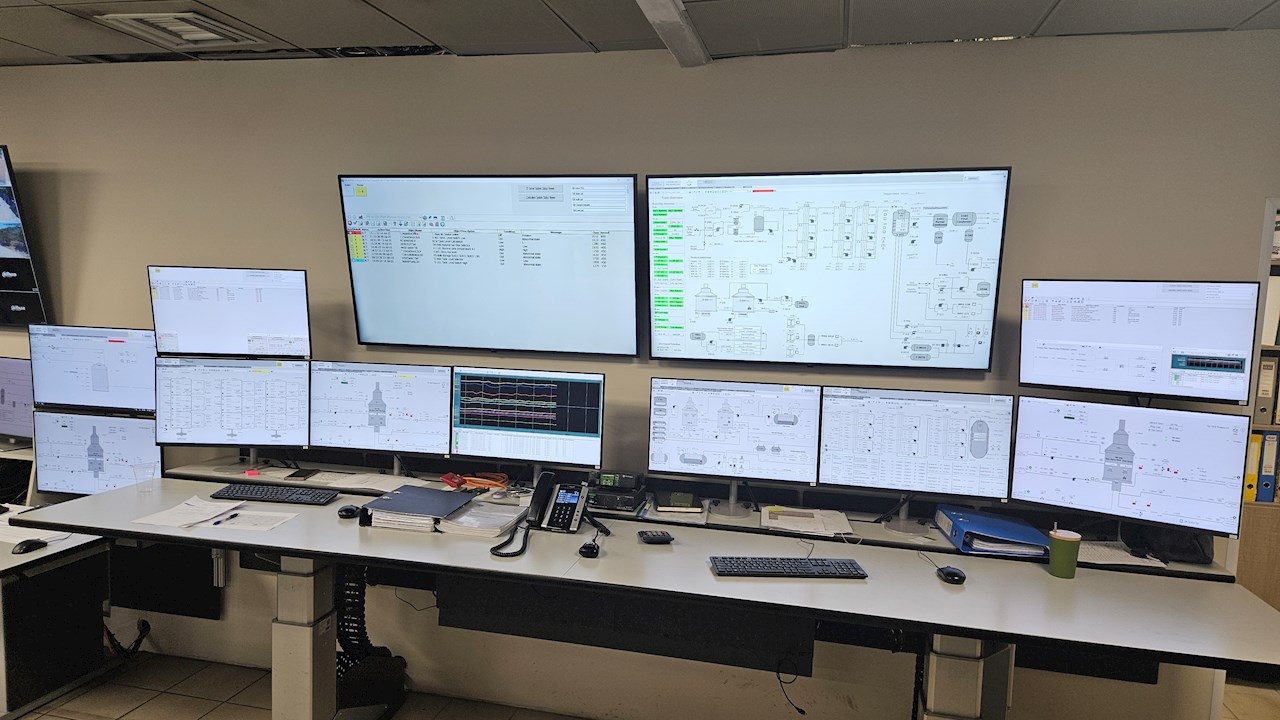

The scope of supply for ABB covered the complete 800xA DCS migration including redundant architecture, engineering stations, operator stations, historian, MES connectivity, virtualization and the latest cyber security features. The contract was booked in the fourth quarter of 2022, and the project duration was approximately 12 months from kickoff to full commissioning.

The project was delivered using ABB’s Adaptive Execution™ methodology – an integrated, digitally enabled approach that combines standardized workflows, early-stage collaboration, and modular execution. This framework empowered the project team to proactively identify and address potential challenges, implement design refinements early, and maintain schedule discipline. The result was a streamlined execution that achieved measurable reductions in both cost and time.

Digitalization and sustainability benefits

The 800xA implementation supports Ravago’s digital transformation initiatives since it allows system virtualization and includes the integrated historian for process traceability and MES logging. Furthermore, remote access and NIS2 cyber security readiness, as well as possibilities for a digital twin expansion, are enabled.

Process efficiency was improved since the new DCS now gives the plant improved operational reliability, eliminating emergency shutdowns and associated energy waste. The tighter control of the line also provides safer operation, thereby minimizing environmental risks to the local community.

Mutual success: DCS migration strengthens long-term ABB-Ravago collaboration

“The Ravago project demonstrates what can be achieved when local expertise is combined with global engineering excellence,” said Fotis Fotopoulos, Digital Manager in ABB’s Energy Industries division. “This project proves what ABB’s Adaptive Execution can accomplish – seamless, risk-mitigated DCS modernization for a critical process. Ravago’s confidence in awarding us a three-year ABB Care agreement speaks volumes about the long-term value we deliver.”

Ravago’s Maintenance & Project Manager, John Papanikolaou, is equally satisfied with the results of the DCS migration. “The transition from MOD5 to ABB Ability System 800xA was executed flawlessly without a single production interruption – which was critical for our continuous PS manufacturing process,” said Mr. Papanikolaou. “ABB's Adaptive Execution gave us confidence throughout the project, and the new system has already enhanced our operational reliability while positioning us perfectly for future digital transformation initiatives. The local support from ABB Greece was exceptional, and their deep understanding of our unique production requirements has made all the difference.”