RML Machinery designs and engineers precision industrial automation and material handling solutions that elevate performance and modernise industrial operations.

Based in Hamilton, New Zealand, the company has been delivering automation systems to the FMCG, dairy, material handling, and industrial industries for over 40 years. Specialising in improving production equipment for filling, packing, and logistics applications, RML Machinery is driven by a commitment to designing solutions that improve production flow and increase efficiency for its customers. Following almost two decades of integrating ABB robots into their systems, RML Machinery has now qualified to become ABB New Zealand’s newest Authorized Value Provider (AVP).

“We’ve had great success integrating ABB’s industrial articulated robots like the IRB 660, IRB 460, and later models such as the IRB 2600 and IRB 1300 - into our systems to help customers overcome complex and long-standing challenges in their packing, picking, and palletizing applications for everyday consumer products.

Their customer base includes an impressive lineup of companies including Fonterra, Wilmar International, Froneri, George Weston Foods, Lactalis, and Goodman Fielder. “Without the support of trusted partners producing high-quality technology – like ABB Robotics - we wouldn’t be able to deliver the top-performing, pioneering solutions our customers rely on across the Asia Pacific region,” said Aron.

As an ABB Robotics AVP, RML Machinery will benefit from expert support via both local and global specialists. Additionally, they will have access to ABB’s RobotStudio®, an offline programming and simulation tool offering users advanced robot programming and optimisation for testing, validation, and visualisation. This comprehensive support ensures AVPs are equipped with the resources to drive success in their projects and operations and deliver faster implementation of solutions for their customers.

"As an ABB Robotics AVP, we’ve supported our already experienced technicians to upskill further."

“We pride ourselves on our consultation, design, engineering, service, and commissioning capabilities which are always delivered with a genuine dedication to helping companies that are the backbone of their communities success. As an ABB Robotics AVP, we’ve supported our already experienced technicians to upskill further, enabling them to provide even more recommendations to our customers thanks to certifications in robotic programming. This expertise allows our team to consistently help customers identify the best options for upgrading their machines, whether it be for end-of-life replacement, retrofits or better precision control using robotic and vision automation,” said Aron.

Elaborating further, Aron explains that achieving ABB AVP status reinforces that RML Machinery is no ordinary system integrator, but one that excels in being a trusted partner with deep product knowledge. By aligning itself with an industry leader like ABB, RML demonstrates its drive to stay current with the latest technology trends, tools, and best practices, allowing the company to deliver world-class systems with both local and global support.

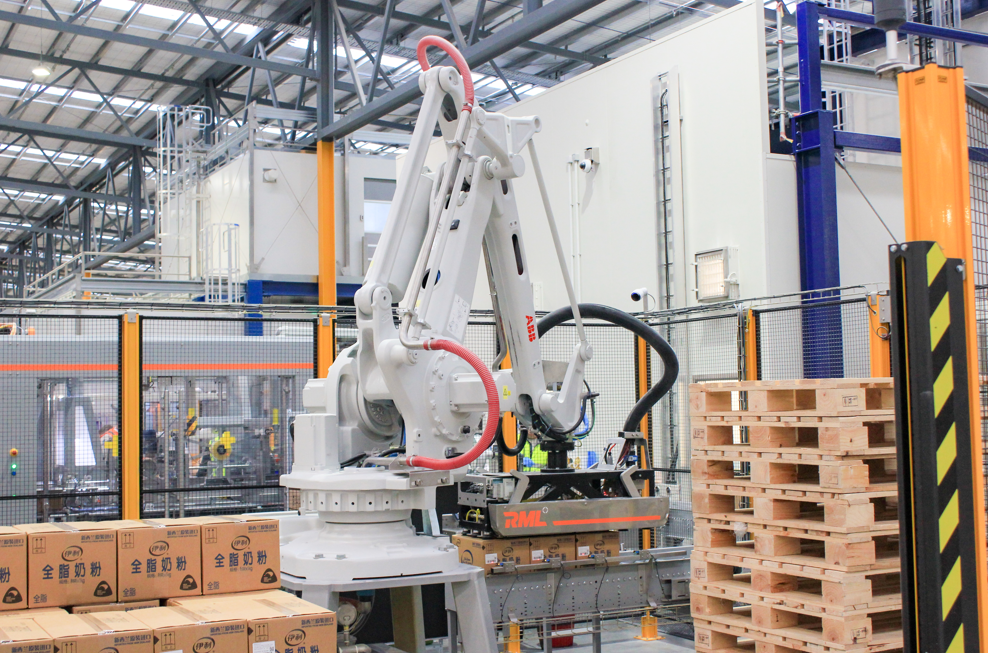

A milk powder bag track and trace case packer and palletiser system designed by RML Machinery and supplied to Oceania Dairy.

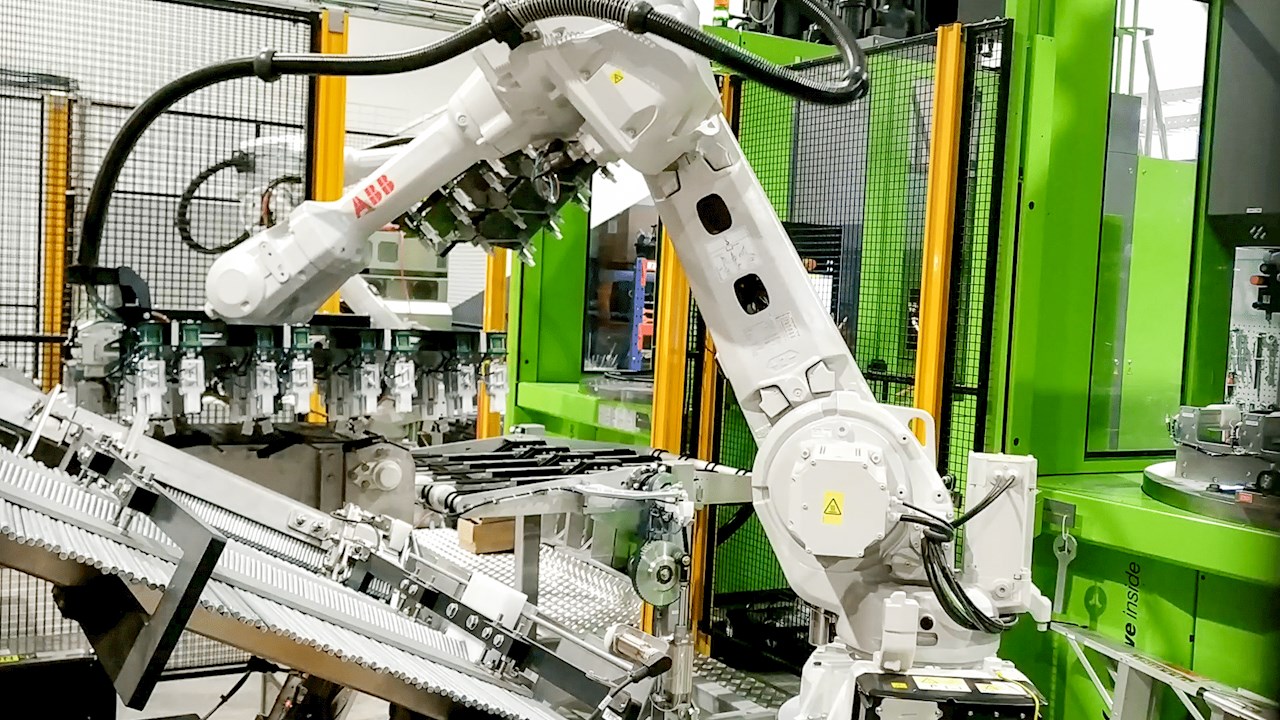

An injection machine loader system designed by RML Machinery played a key role in helping Gallagher Group re-shore its manufacturing operations back to New Zealand.

A premium honey jar top load case packer system designed by RML Machinery and supplied to Comvita.

An ABB industrial robot transferring cases containing 20kg Frozen Milk Concentrate Bags, as part of a system designed for an RML client.

A case packing and palletising line, designed by RML, streamlines the packaging process for Hubbards cereal boxes.

An alternate view – the custom-built case packing and palletising line for Hubbards cereal boxes.

(L-R): Alex Chaloner, Automation Team Leader for RML Machinery; Peter Bradbury, Channel Manager for ABB Robotics Australia & New Zealand; Aron May, Sales Executive for RML Machinery.

A testament to RML Machinery’s success, the company has continually enabled its customers to reduce costs, boost productivity, and minimise unplanned downtime since integrating robots into their customised systems.

One example is Oceania Dairy, which approached RML to assist in overcoming challenges in automating a manual case packing and palletising application. Established to meet the growing international demand for New Zealand milk powder - an internationally recognised and respected source of highly valued dairy nutrition that nourishes people for better, healthier lives – Oceania Dairy was also seeking a solution that ensured full product traceability.

In addition to automating the packing and palletising process, the company required a system that could track each pouch from the filling room, through to case packing, and finally onto the pallet, for comprehensive and reliable traceability for quality control and compliance purposes.

The solution is a new top-load case packing system that integrates product orientation, RSC erecting, robotic loading (using the RML Hawk robotic loading system), and tape closing to efficiently load foil milk powder pouches into cases and seal them for palletising.

The closed cases are then conveyed to the palletising system where each case is scanned and collated. An ABB industrial robot picks the collated cases from the conveyor and places them onto a pallet, diligently following a pre-determined pattern. The robot stacks the cases layer by layer until the pallet is full. Once fully loaded, the pallets are seamlessly conveyed to staging zones, where they are either held for forklift operator pickup if needed, or accumulated until the conveyor is filled with pallets of cases.

“The commitment of RML to high-quality service is at a level we had not seen before,” said Robbie Breen, Canning & Pouch Production Manager at Oceania Dairy. “RML are consistently solution-oriented, and have always been ready to help, even during the hard times. The trust and reliance that has grown out of this partnership has led to us achieving numbers we previously did not think would be possible.”

RML Machinery also played a key role in assisting Gallagher Group in reshoring the manufacturing of their Ring Top Fence Standards to New Zealand. Gallagher required a robotic solution capable of processing a vast range of fence SKUs (from full Fence Standards to the multitude of supplementary parts) that make up their fencing product line.

To overcome this challenge, RML designed a two-cell system. One cell manufactures the foot end of the Standard, while the second completes the assembly by adding the Ring Top. Each cell is equipped with an ABB IRB 4600 robot, responsible for all product handling and transferring components between cells.

The solution has provided Gallagher with greater control of their product quality, expanded their SKU processing capabilities, and allowed them to manage their international supply chain from their home base in New Zealand.

Peter Bradbury, Channel Manager for ABB Robotics Australia & New Zealand, said, “The RML team has proven itself to be an outstanding engineering company with a solid reputation and loyal clients on both sides of the Tasman. They’re already well recognised in major FMCG and industrial sectors in Australia and New Zealand, and I have no doubt that their newly acquired AVP status will catapult them to greater visibility and recognition - both within ABB and through new collaboration opportunities with other like-minded companies in the APAC market.”