- Application: Automated handling and palletizing of folded leaflets in a high-speed commercial printingenvironment.

- Challenge: Skilled labor shortages and difficulty staffing night and weekend shifts made it hard for cobot expertVulcan Automation’s end customer to keep up with production demands. Operators were spendingvaluable time on repetitive manual tasks instead of optimizing machine performance.

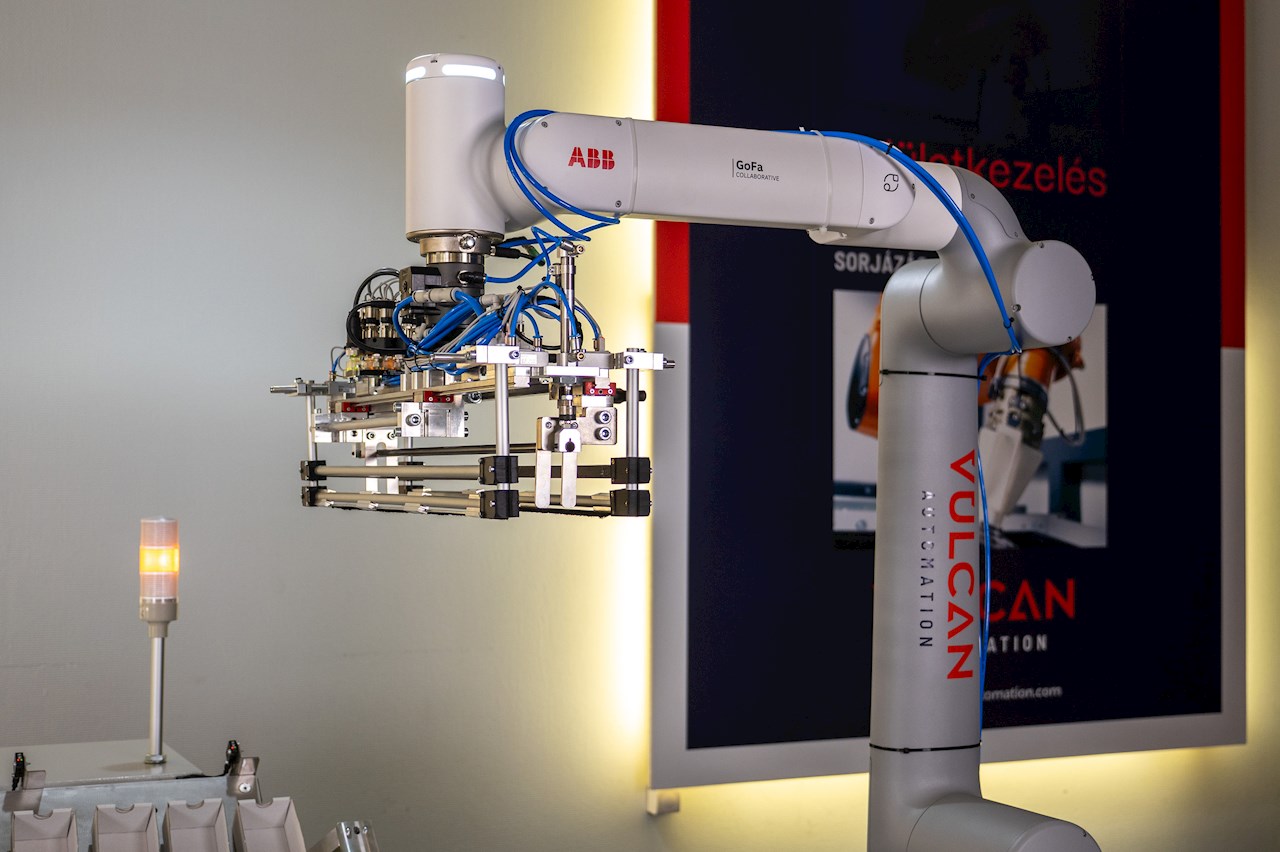

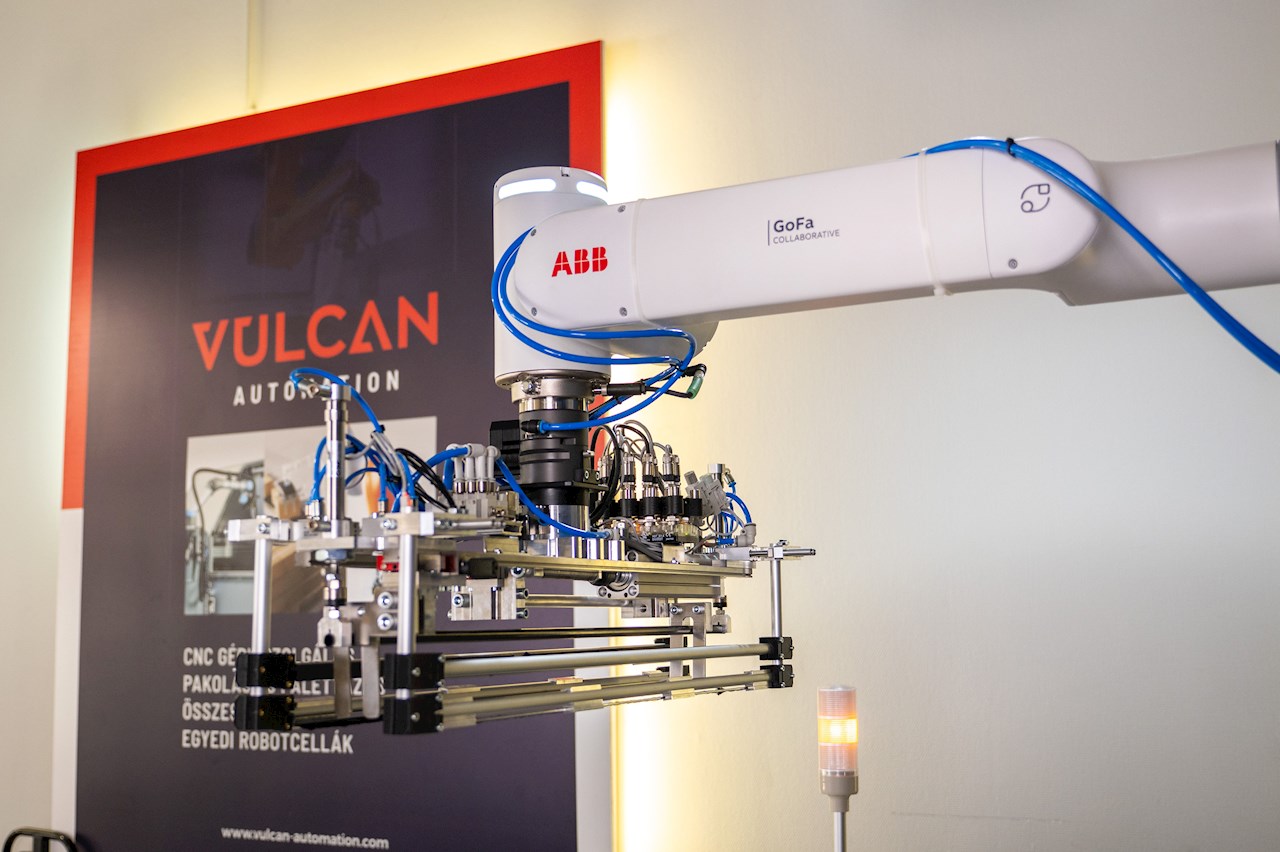

- Solution: The cobot expert developed a flexible robotic cell powered by ABB’s GoFa™ cobot. The solutionautomates leaflet placement into trays and palletizing, using dual grippers and advanced partorientation handling, freeing operators for higher-value work and enabling scalable, round-the-clockproduction.

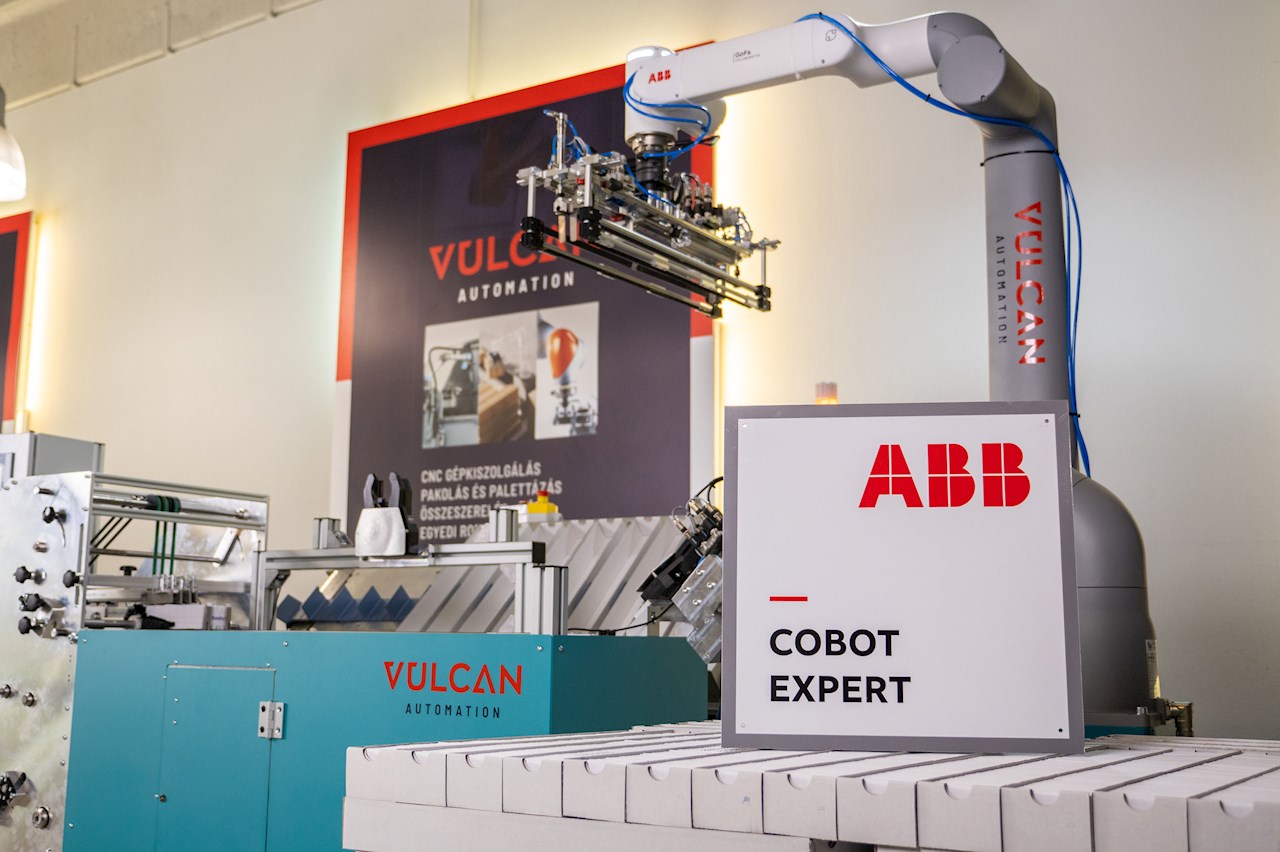

Vulcan Automation, a trusted Hungarian system integrator and a valued ABB cobot expert, renowned for deliveringcustomized cobot solutions across manufacturing, logistics, and printing industry, was approached by a leadingGerman printing house facing a critical operational challenge. Specializing in folded print materials for the cosmetics and pharmaceutical sectors. The customer needed a way to maintain high-speed production without overburdening their workforce. Like many in the industry, they struggled to find skilled operators willing to work on repetitive tasks like placing folded leaflets into trays and palletizing them. These monotonous duties not only drainproductivity but also affect operator’s wellbeing and retention.

As part of ABB’s Cobot Expert Program, Vulcan Automation benefited from specialized training, technical support,and access to cutting-edge collaborative robotics technology. This expertise enabled them to confidently design andimplement a tailored automation solution. Partnering with Vulcan Automation, the customer deployed a state-ofthe-art robotic cell centered around ABB’s collaborative and best-in-class GoFa cobot. The robotic cell is designed tomanage the entire post-print process: turning the leaflets 180 degrees when necessary for sampling and precisecounting, performing quality checks, and placing precise quantities into paper trays. Once a tray is full, GoFa automatically switches to a wider gripper to stack trays onto pallets. The precise motion control and tactile sensing capabilities of the cobot together with the gripper, securely pick the leaflets and position them, all without operatorintervention. The entire system is engineered for flexibility, allowing operators to configure leaflet sizes, tray dimensions, and pallet patterns via a user-friendly interface.

‘We chose the ABB GoFa because its long reach allows us to build taller pallets than with any other similar robotic arm, and we were already familiar with ABB’s software from our previous industrial robotics projects.’ Ákos Dömötör, CEO Vulcan Automation

The cobot expert chose the 10kg payload GoFa for its 14% longer reach and unique kinematic design, which offerssuperior orientation flexibility compared to other cobots. Additionally, the powerful software integration made itpossible through RobotStudio® and the user-friendly wizard easy programming, accelerated the development cycleand enhanced overall performance.

‘With a return on investment expected in under two years, the customer is now better equipped to scaleproduction and confidently accept new orders.’ Ákos Dömötör, CEO Vulcan Automation

By automating the repetitive task of tray and pallet handling, skilled operators can redirect their focus to optimizingprinting operations. With the flexibility to easily adjust to varying production needs, the customer is now able toexpand operations, reinforcing their leadership in the market.

Working together with cobot experts, ABB’s collaborative solutions are driving efficiency, elevating operational excellence, and unlocking new growth opportunities in complex industrial settings.

By automating the repetitive task of tray and pallet handling, skilled operators can redirect their focus to optimizingprinting operations. With the flexibility to easily adjust to varying production needs, the customer is now able toexpand operations, reinforcing their leadership in the market.Working together with cobot experts, ABB’s collaborative solutions are driving efficiency, elevating operational excellence, and unlocking new growth opportunities in complex industrial settings.

ABB’s Cobot Expert Program is a dedicated initiative for system integrators, distributors and automation enthusiastswho want to gain hands-on experience with ABB’s collaborative robots. The program offers training, tools, and certification to empower partners to lead the future of flexible automation.

Learn more about cobot expert program.

ABB (ABBN: SIX Swiss Ex) is a global technology leader in electrification and automation, enabling a more sustainable and resource-efficient future. By connecting its engineering and digitalization expertise, ABB helps industries run at high performance, while becoming more efficient, productive and sustainable so they outperform. At ABB, we call this ‘Engineered to Outrun’. The company has over 140 years of history and around 110,000 employees worldwide. ABB’s shares are listed on the SIX Swiss Exchange (ABBN) and Nasdaq Stockholm (ABB). www.abb.com

ABB Robotics & Discrete Automation as one of the world’s leading robotics and machine automation suppliers, is the only company with a comprehensive and integrated portfolio covering robots, Autonomous Mobile Robots and machine automation solutions, designed and orchestrated by our value-creating software. We help companies of all sizes and sectors - from automotive to electronics and logistics – to outperform by becoming more resilient, flexible and efficient. ABB Robotics & Discrete Automation supports customers in the transition towards the connected and collaborative factory of the future, operating leaner and cleaner for a better future. The business area employs approximately 11,000 people at over 100 locations in approximately 53 countries. go.abb/robotics

Vulcan Automation Ltd. is a recognized expert in the field of printing and packaging automation, serving an international client base. The company has particular strength in the design and construction of customized collaborative robot cells. www.vulcan-automation.com